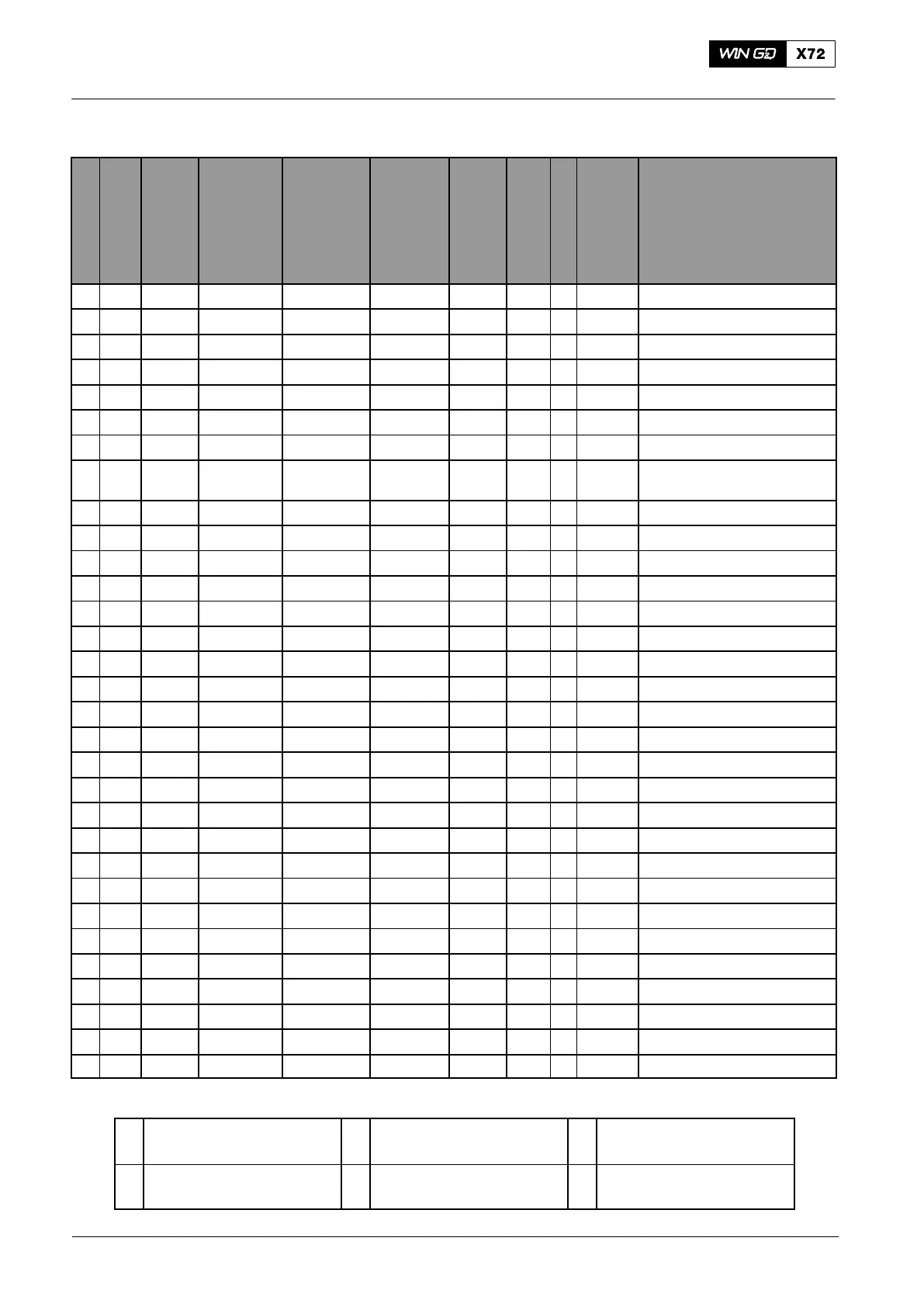

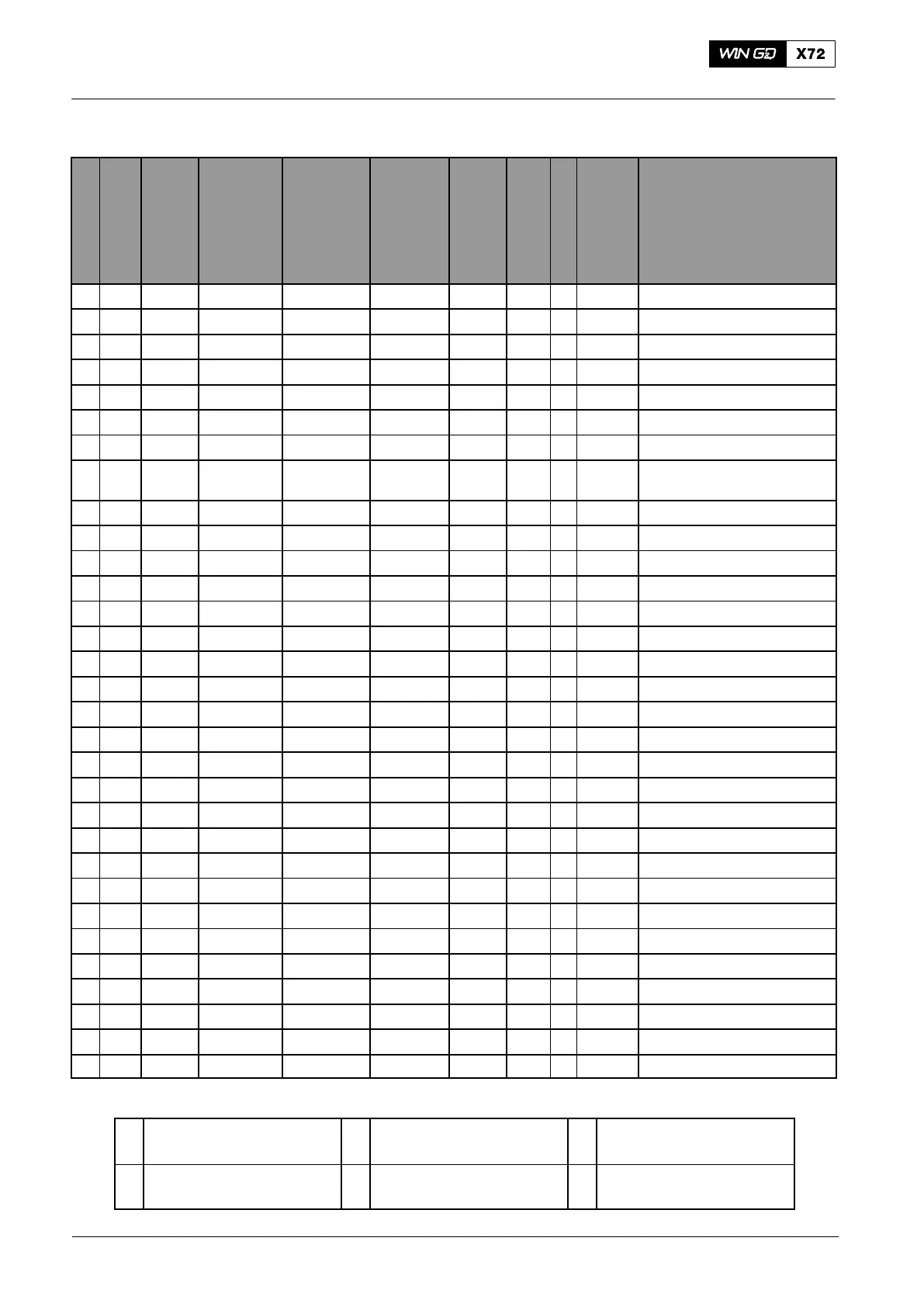

Maintenance0352−1/A1

Winterthur Gas & Diesel Ltd.

8/ 11

Position

Pre-tensioning

pressure (bar)

Tightening torque

or reference torque

(in brackets) [NM]

Step 1

Step 2

Delta L [mm]

Tightening angle

or control angle

(in brackets) [*]

Control angle from

step 1 to step 2 [*]

Lubricant

Thread size

Comments

1 1500 (495) O M85

2 20 Nm

45°

K M12

3

0.5 ±0.04

O M56 See on page 1 position 3

4 225 O M30 Or hand-tight with a spanner

5 136 O M16

6 136 O M16

7 1500 700 bar 1500 bar 65 O M80

8 1500 All screws

with 600 bar

All screws

with 1500 bar

O M48 See on page 1 position 8

9 170 K M64 Hydraulic jack Group 9710

10 1500 1000 bar 1500 bar K M64

11 1500 1100 bar 1500 bar 15 O M56

12 14−15 M

G¾“

13 5 K −

14 150 O M16

15 10 O M10

16 1500 (75) O M33 See on page 1 position 16

17 1500 (165) O M80

18 1500 1000 bar 1500 bar 20 O M33

19 (15800) 41 M M85

20 (900) 50 M M30

21

1.3 ±0.06

M M39

22 1600 (80) K M30

23 3900 (25) M M56

24 (15000) 57 M M85

25 1500 O M60

26 (1200) 65 M M30

27 1500 11.5 to 13.5 M M105

28 300 K M24

29 N M12 See on page 3 position 29

30 100Nm

40°

N M72

31 190 N M36x1.5

M MOLYKOTE PASTE G−N

On threads and contact surfaces

C MOLYSLIP COPASLIP

On threads and contact surfaces

N NEVER SEEZ NSBT8

On threads and contact surfaces

K NO ADDITIONAL LUBRICATION O LUBRICATING OIL SAE 30

On threads and contact surfaces

Tightening Values of Important Screwed Connections

2015

Loading...

Loading...