Overview

Toothsetter Introduction

Overview BMT10013doc082115 1-1

1

SECTION 1 OVERVIEW

1.1 Toothsetter Introduction

There are four steps to maintaining blades used on the Wood-Mizer sawmill. They should

ALWAYS be followed in this order:

1. Blade Cleaning

2. Sharpening

3. Deburring

4. Toothsetting

See Figure 1-1. The blades supplied by Wood-Mizer have a raker-style set in the teeth. If

you look at a blade from the top, you will see that the teeth are set (or bent out) in a

repeating sequence; straight, left and right. The teeth that are set left and right do the cut-

ting. The straight teeth (rakers) clear the cut of sawdust.

See Figure 1-2. As the blade is sharpened, the tip of the tooth recedes and the set

becomes smaller. Correct setting is one of the most important factors in the cutting ability

of a blade. Check used blades regularly to see if they need resetting.

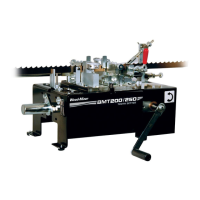

The BMT100-2/BMT100-3 Toothsetter allows you to accurately and evenly set the teeth

of a bandsaw blade. The spring-loaded clamping mechanism lets you position a tooth in

front of the gauge and clamp it in place. You can then measure the set. The tooth is bent

by clamping the blade further. This chapter describes proper setup and operation of the

toothsetter.

FIG. 1-1

FIG. 1-2

Set After

Sharpening

Original

Set

Loading...

Loading...