Setup & Operation

Tensioning The Blade

Setup & Operation HDSdoc091108 2-8

2

2.5 Tensioning The Blade

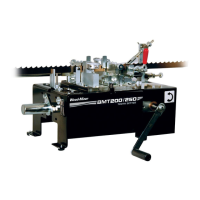

See Figure 2-5. Tension the blade by turning the hydraulic tensioning handle clockwise until the

tension gauge indicates the recommended tension.

See Table 2-1. The recommended tension for different blades is shown below.

The tension gauge should be checked occasionally when adjusting the cant control or while cut-

ting. Ambient temperature changes will cause tension to change. Adjust the tension handle as

necessary to maintain the recommended tension level.

CAUTION! Changes in temperature could cause increased

pressure in the blade tensioner and loss of fluid from the gauge.

Release the blade tension when the mill is not in use to avoid

damage to the tensioner.

FIG. 2-5

Blade Type Acceptable Range Ideal Tension

B375IH929 12,4 - 14,5 MPa (1800 - 2100 psi) 13,8 MPa (2000 psi)

B275IH1030 14,5 - 16,5 MPa (2100 - 2400 psi) 15,9 MPa (2300 psi)

B275IH741030 14,5 - 16,5 MPa (2100 - 2400 psi) 15,9 MPa (2300 psi)

TABLE 2-1

SM0243

Blade Tensioner

Gauge

Cant Control

Blade Tensioner

Handle

Loading...

Loading...