EGCP-2 Engine Generator Control Package Manual 26086

52 Woodward

100

20mA

-100

4mA

0

speed bias ->

0

100%

Figure 3-30. Direct (Import/Export) Process Action

(This example is using a 4–12–20 mA transducer.)

Process Import/Export Hardware

• EGCP-2 Control can take a 4–20 mA, or 1–5 Vdc input signal from a

transducer. Input signal conditioning is selected by a dip switch on the back

of the control, switch position 4, switch number 4. Closing this switch selects

the 4–20 mA input hardware. Opening this switch selects the 1–5 Vdc input

hardware. See the EGCP-2 layout diagram for switch location on the unit.

1

2

3

4

Dip Switch # 4

SW - 4

___________________________

1. +5V RS-485

2. 123 ohm RS-485 Termination+

3. 123 ohm RS-485 Termination -

4. 4-20 mA Process Input

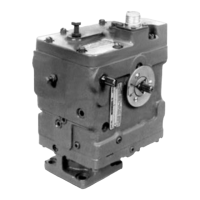

Figure 3-31. EGCP-2 Control Dip Switch

Process Dynamics

• Process Master Uses Process PID to control.

• Gain, Stability, Derivative, Filter, Droop.

• Slaves to the Process Master use Load Control PID Values to track master

system load reference.

• Load Gain, Stability, Derivative, Filter.

Process Gain

• Sets system gain response while in process control.

• Effective at active master unit only. Slaves rely on Load Control dynamic

settings to control response to master load reference.

• Should be set with maximum number of units operating in process control

mode.

Loading...

Loading...