WORKHORSE CUSTOM CHASSIS

Service Manual

W SeriesWCC

SECTION

6.2

PAGE

23

Engine Mechanical

W Series Chassis

TOC

© 2006 WorkhorseCustom Chassis — All Rights Reserved

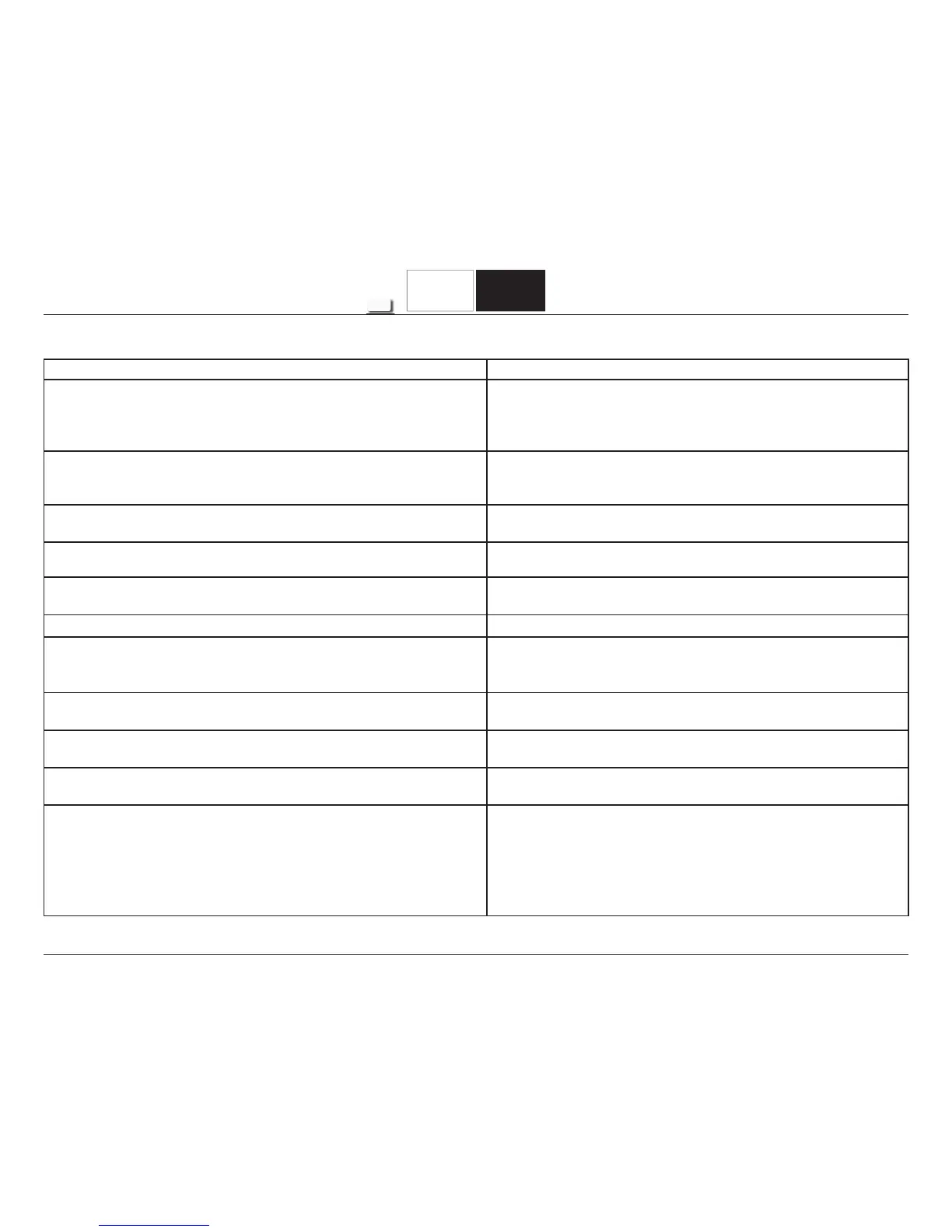

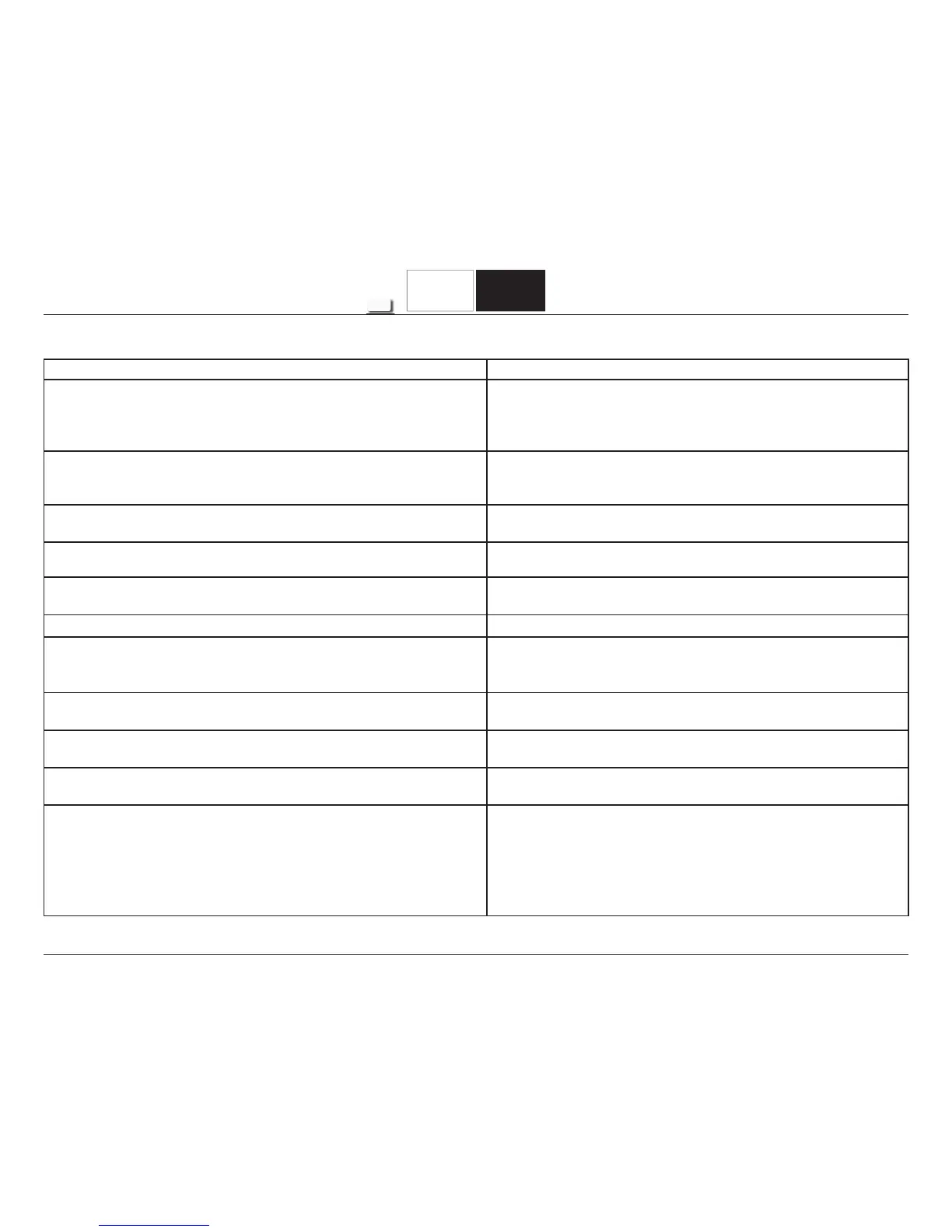

LOWER ENGINE NOISE, REGARDLESS OF ENGINE SPEED

Cause Correction

Low oil pressure 1. Verify proper oil level.

2. Perform an oil pressure test. Refer to Oil Pressure Diagnosis and

Testing .

3. Repair or replace damaged components, as required.

Worn accessory drive components

Abnormalities, such as severe cracking, bumps, or missing areas in the

accessory drive belt and/or misalignment of system components.

1. Inspect the accessory drive system.

2. Repair or replace, as required.

Loose or damaged crankshaft balancer 1. Inspect the crankshaft balancer.

2. Repair or replace, as required.

Detonation or spark knock Verify the correct operation of the ignition controls system. Refer to

Detonation/Spark Knock .

Loose torque converter bolts - automatic transmission only 1. Inspect the torque converter bolts and fl ywheel.

2. Repair or replace, as required.

Loose or damaged fl ywheel Repair or replace the fl ywheel.

Damaged oil pan contacting the oil pump screen

An oil pan that has been damaged may improperly position the oil pump

screen, preventing proper oil fl ow to the oil pump.

1. Inspect the oil pan.

2. Inspect the oil pump screen.

3. Repair or replace, as required.

Oil pump screen loose, damaged, or restricted 1. Inspect the oil pump screen.

2. Repair or replace, as required

Excessive piston-to-cylinder bore clearance 1. Inspect the piston and cylinder bore.

2. Repair, as required.

Excessive piston pin-to-bore clearance 1. Inspect the piston, piston pin, and connecting rod.

2. Repair or replace, as required.

Excessive connecting rod bearing clearance 1. Inspect the following components:

• The connecting rod bearings

• The connecting rods

• The crankshaft

• The crankshaft journals

2. Repair, as required.

Loading...

Loading...