WORKHORSE CUSTOM CHASSIS

Service Manual

W SeriesWCC

SECTION

6.2

PAGE

4

Engine Mechanical

W Series Chassis

TOC

© 2006 WorkhorseCustom Chassis — All Rights Reserved

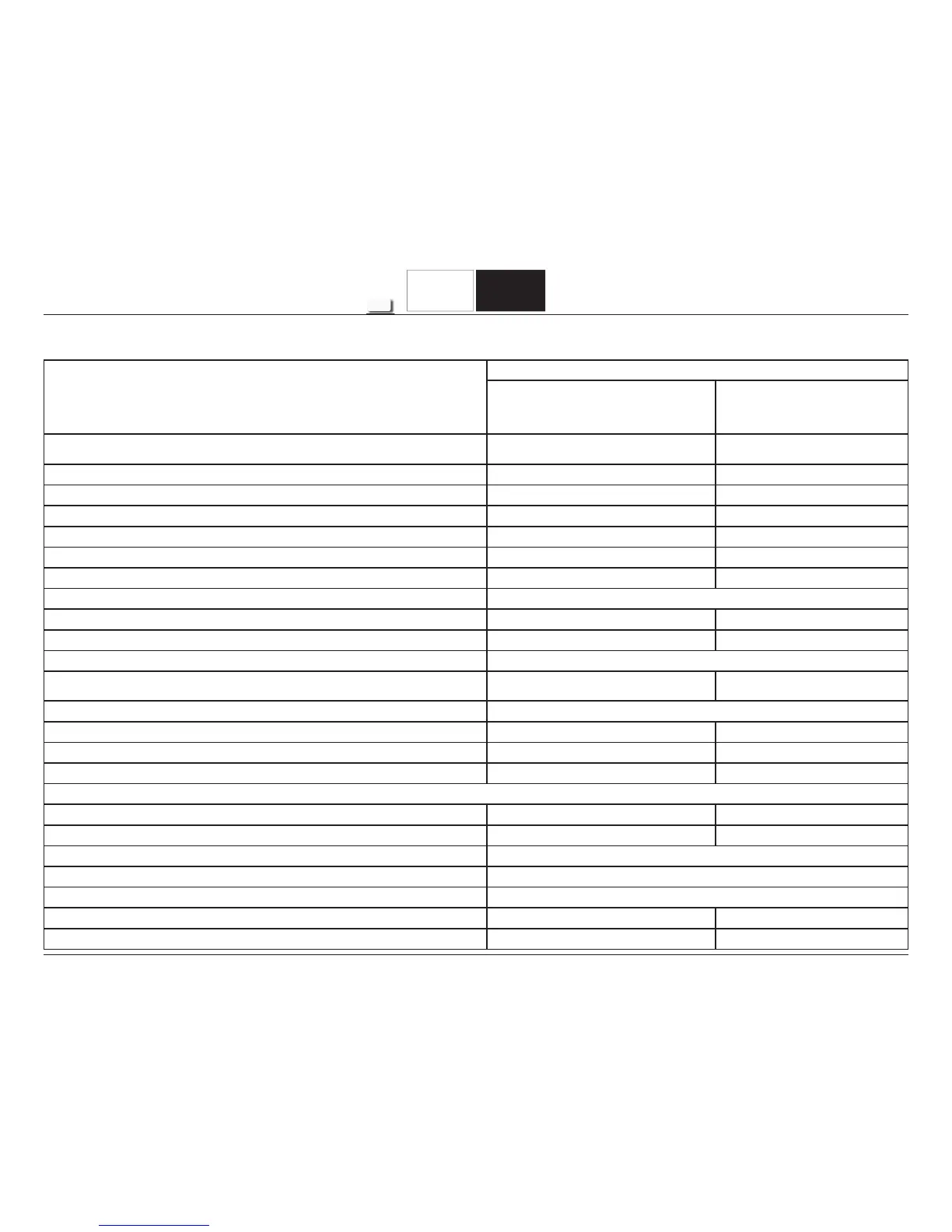

FASTENER TIGHTENING SPECIFICATIONS

L18 (8.1L) ENGINE

Application

Specifi cation

Metric English

Air Cleaner Outlet Duct Clamp 4 N·m 35 lb in

Air Conditioning (A/C) Belt Tensioner Bolt 50 N·m 37 lb ft

Battery Cable Channel Bolt 9 N·m 80 lb in

Camshaft Position (CMP) Sensor Bolt 12 N·m 106 lb in

Camshaft Retainer Bolt 12 N·m 106 lb in

Camshaft Sprocket Bolt 30 N·m 22 lb ft

Connecting Rod Nut - First Pass 30 N·m 22 lb ft

Connecting Rod Nut - Final Pass 90 degrees

Crankshaft Balancer Bolt 255 N·m 189 lb ft

Crankshaft Bearing Cap Bolts - First Pass 30 N·m 22 lb ft

Crankshaft Bearing Cap Bolts - Final Pass 90 degrees

Crankshaft Bearing Cap Studs - First Pass 30 N·m 22 lb ft

Crankshaft Bearing Cap Studs - Final Pass 80 degrees

Crankshaft Oil Defl ector Nut 50 N·m 37 lb ft

Crankshaft Position (CKP) Sensor Bolt 12 N·m 106 lb in

Crossbar Bolt 100 N·m 74 lb ft

Cylinder Head Bolts - In Sequence

• First Pass 30 N·m 22 lb ft

• Second Pass 30 N·m + 120 degrees 22 lb ft + 120 degrees

• Final Pass - Long Bolts #1, 2, 3, 6, 7, 8, 9, 10, 11, 14, 16, 17 60 degrees

• Final Pass - Medium Bolts #15, 18 45 degrees

• Final Pass - Short Bolts #4, 5, 12, 13 30 degrees

Cylinder Head Coolant Hole Plug 50 N·m 37 lb ft

Drive Belt Idler Pulley Bolt 50 N·m 37 lb ft

8.1L (L18) ENGINE

Loading...

Loading...