Page 20

The X-Terminator 2 RTR 4WD Nitro Buggy features front, centre and rear gear differentials that each feature o-ring seals and cup-style

housings. All three differentials are packed with differential grease that is good for most driving conditions.

You can make ne-tuned adjustments to each differential by removing the differentials from the chassis, opening them up and replacing

the grease already inside the differentials with silicone differential oil.

●

Front and Rear Differentials: Adding heavier silicone oil will tighten the differentials and adding lighter silicone oil will loosen

the differentials. If your X-Terminator 2 RTR 4WD Nitro Buggy feels 'loose' (uncontrollable) during turns, you can tighten the

front differential or loosen the rear differential. If your Nitro Buggy is 'pushing' (understeer) during turns, you can loosen the front

differential or tighten the rear differential.

●

Centre Differential: For the centre differential, using a lighter weight oil will cause the differential to unload easier. Generally, this is

good for loose tracks with little traction. Using a heavier weight will provide a more even amount of power to the front and rear. On loose

tracks, this can cause the X-Terminator 2 RTR 4WD Nitro Buggy to be too 'squirrely' (uncontrollable) or cause the rear end to slide out.

For this reason, we only suggest using heavier oil if you are driving on a high-traction surface.

For general use, we recommend using XTM Racing 50K oil in the centre, 30K in the front and 10K in the rear. Some might consider

this light, but it's a pretty good starting point. If the track or tyres seem to have a lot of traction, then you might use 70K in the centre,

50K in the front and either 50K or 30K in the rear.

For your convenience, we show you how to remove and disassemble the front differential. Removing and disassembling the

centre and rear differential is similar.

●

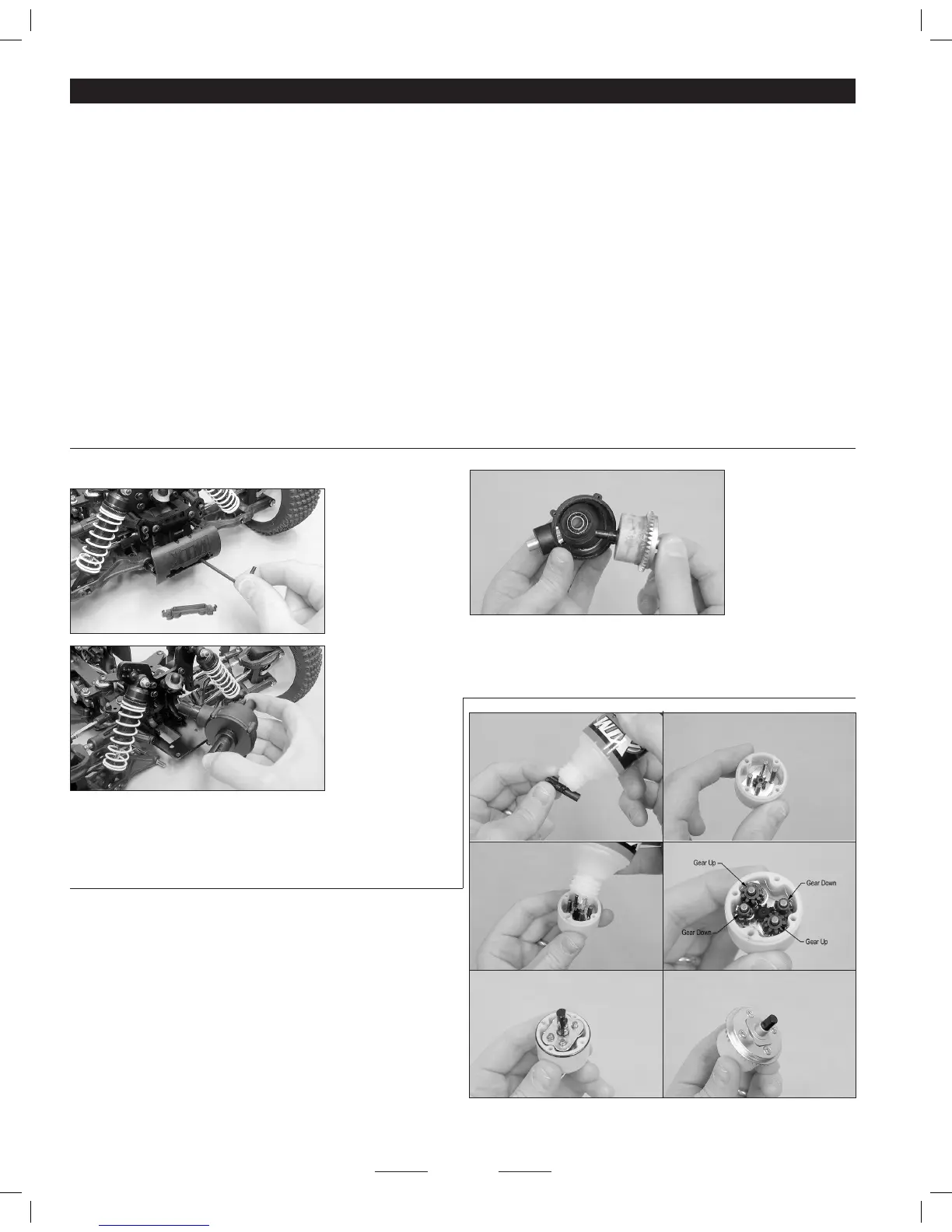

Remove the screws from the bottom of the chassis that hold the

front bumper and the differential assembly in place.

●

Use a small flat

blade screwdriver to

pry the screw cover off

the front of the bumper

and remove the two

screws from inside the

bumper, then remove

the bumper.

●

Next, remove the

upper hinge pins, then

remove the screws

that hold the upper

hi nge pin sup port

p l a t e i n p l a c e .

R e move the upper

and lower hinge pin

support plates.

●

Pull the front half of the diff case straight out, then remove the

hinge pins and drop the lower suspension arms and pull the diff

assembly straight out.

●

Remove the two CVD drive shaft cups from the diff assembly,

then remove the four

screws that hold the

diff halves together.

●

Pull the diff halves

apart, then pull the diff

assembly (w/ring gear

attached) out of the

diff housing.

●

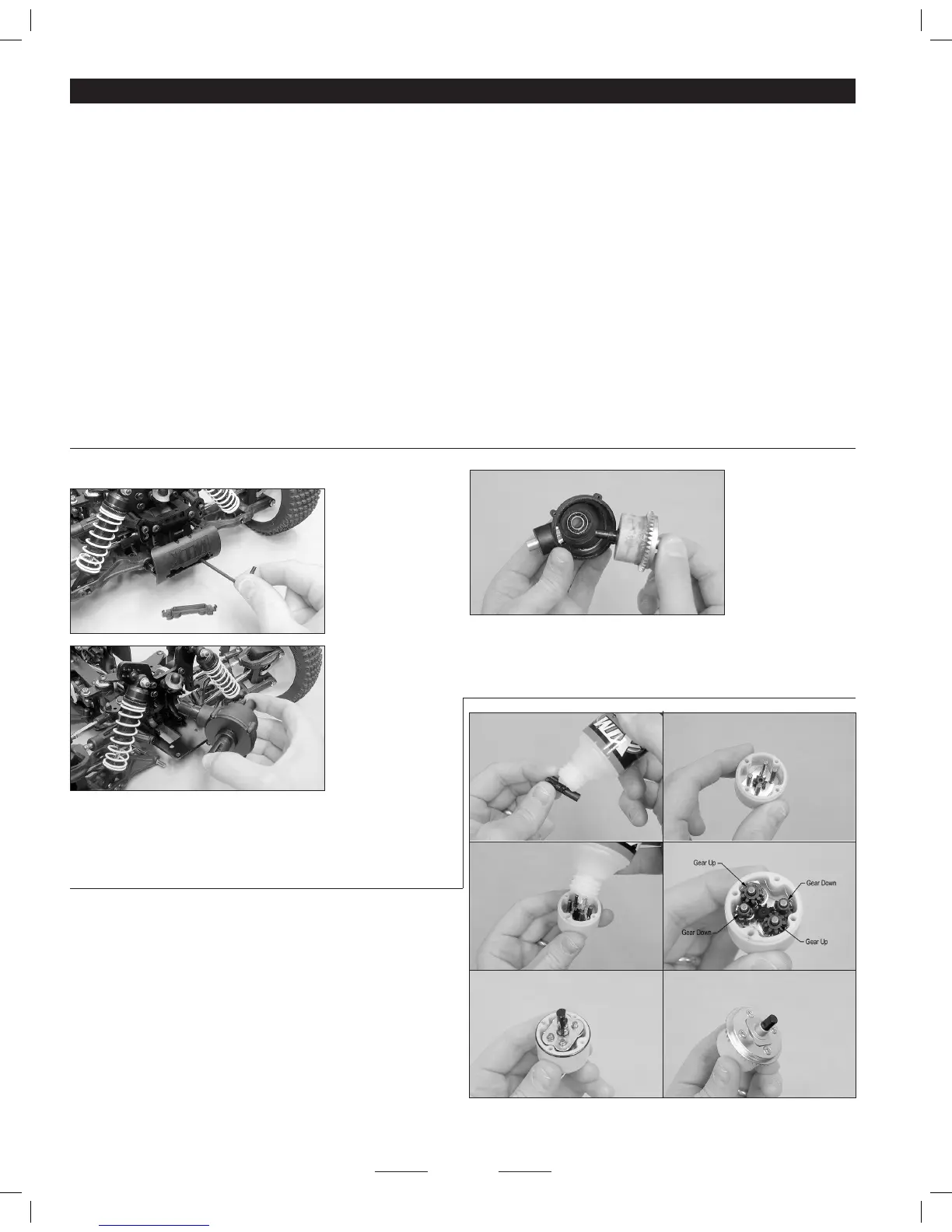

Remove the four screws that hold the diff case together, then pull

the diff case apart to open up the diff. You can now remove the

grease inside the diff and rell the diff with the differential oil

of your choice, using the instructions below.

Figure 1

Figure 2

Figure 3 Figure 4

Figure 5 Figure 6

1) Apply a light coat of silicone diff oil to the output gear o-rings. DO NOT install the

output gears dry or the diff may leak (gure 1).

2) Install one metal plate, one output gear and the four diff pins into the diff cup

(gure 2).

3) Fill the diff cup 2/3rds of the way full with your choice of silicone diff oil (gure 3).

4) Install the diff gears onto the pins. NOTE: Notice the direction that each gear

is installed (gure 4).

5) After installing the diff gears, ll the diff cup completely with diff oil, then let it "rest"

until any trapped air bubbles disappear. SEE NOTE BELOW.

6) Apply a light coat of silicone diff oil to the large o-ring, then install the o-ring over the

"step" in the diff cup. Next, install the second output gear and metal plate (gure 5).

7) Press the metal diff end-cap into place, then install the ring gear. Tighten the four screws

equally in a criss-cross fashion to prevent warping the diff cup or ring gear (gure 6).

NOTE: It's important that there are no air bubbles in the diff oil. Having too much air in the differential will cause the oil to work inconsistently and result in

poor vehicle performance.

Loading...

Loading...