31

©

2019 Columbus McKinnon Industrial Products GmbH

E

LECTRICAL

C

ONNECTION

ATTENTION: Work at electrical installations may be carried out by el ectrical experts only. The local regulations have to be

strictly observed, e.g. EN 60204-32 / VDE 0113.

Preparation

Before beginning work on electrical components the mains current switch must be switched OFF and secured against unintentionally

being switched back on.

Before connecting the chain hoist ensure that the electrical data on the nameplate match the local supply specifications.

• The mains supply cable must be an insulated cable with 4 flexible leads. The ground (earth) lead must be longer than the live leads.

Cable ends have to be provided with end sleeves.

• The cross-sections and the fusing of the various models and cable lengths see tables.

Control switch connection

• The length of the pendant control cable is determined by working conditions. Attach the tension relief wire in a manner that the

pendant control cable hangs load-free. Cable ends have to be provided with end sleeves.

• Wiring and terminal connecting diagrams are included with the hoist.

Mains Supply Connection

1. The mains supply cable must be connected to the electric chain hoist before it is connected to the mains supply.

2. On chain hoists with an electric trolley (CPE-VTE) the three phases of the mains supply are to be connected to the terminal strip

within the terminal box on the trolley. The ground/earth wire is to be connected to the special ground/ earth connection within the

terminal box of the chain hoist.

3. On chain hoists without electric trolley the mains supply and the ground/earth wire are to be connected to the terminal strip within the

terminal box of the chain hoist.

4. After removing the terminal box cover, connect the wiring as shown on the wiring diagram label inside the terminal box cover.

Attention: On hoists with direct control the ground/earth wire should always be connected according to the wiring diagram.

Should the mains supply source not provide a ground (earth) connection please consult the manufacturer.

5. After replacing the terminal box cover, connect the other end of the supply cable to the mains supply.

6. Check the motor's direction of rotation.

The wiring diagram included has been drawn for a normal, clockwise rotating installation.Should the user's mains supply not fulfil these

requirements, e.g. the hoist lowers when ''lift'' is selected (or vice versa) switch the unit OFF immediately and exchange two of the three

phase connections in the mains connection.

Attention: Under no circumstances may the wiring in the pendant control be tampered with.

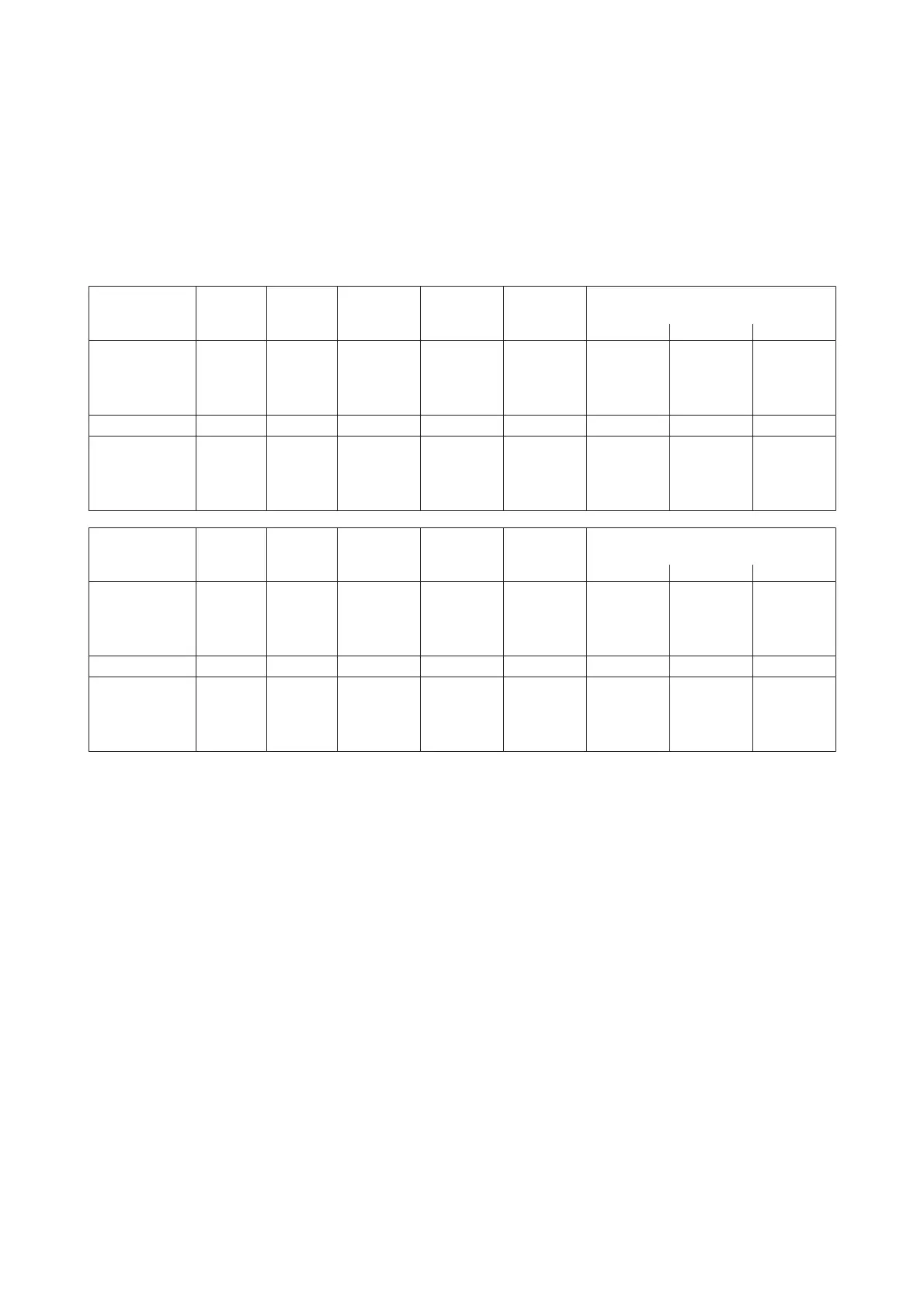

Model

P

n

[kW]

ED

[%]

I

a

/I

n

I

n

[A]

Fuse

(delayed-action)

[A]

Wire cross-section mm

2

for wire length

0 - 50 m 50 - 100 m 100 - 150 m

CPE 16-8

CPE 25-5

CPE 32-4

CPE 50-2

2,3 40 4,7 5,3 16* 1,5 1,5 2,5

CPE 100-2 2 x 2,3 40 4,7 6,4 16* 2,5 2,5 —

CPE 20-8

CPE 30-5

CPE 40-4

CPE 75-1,6

2,8 25 4,7 6,4 16* 2,5 2,5 —

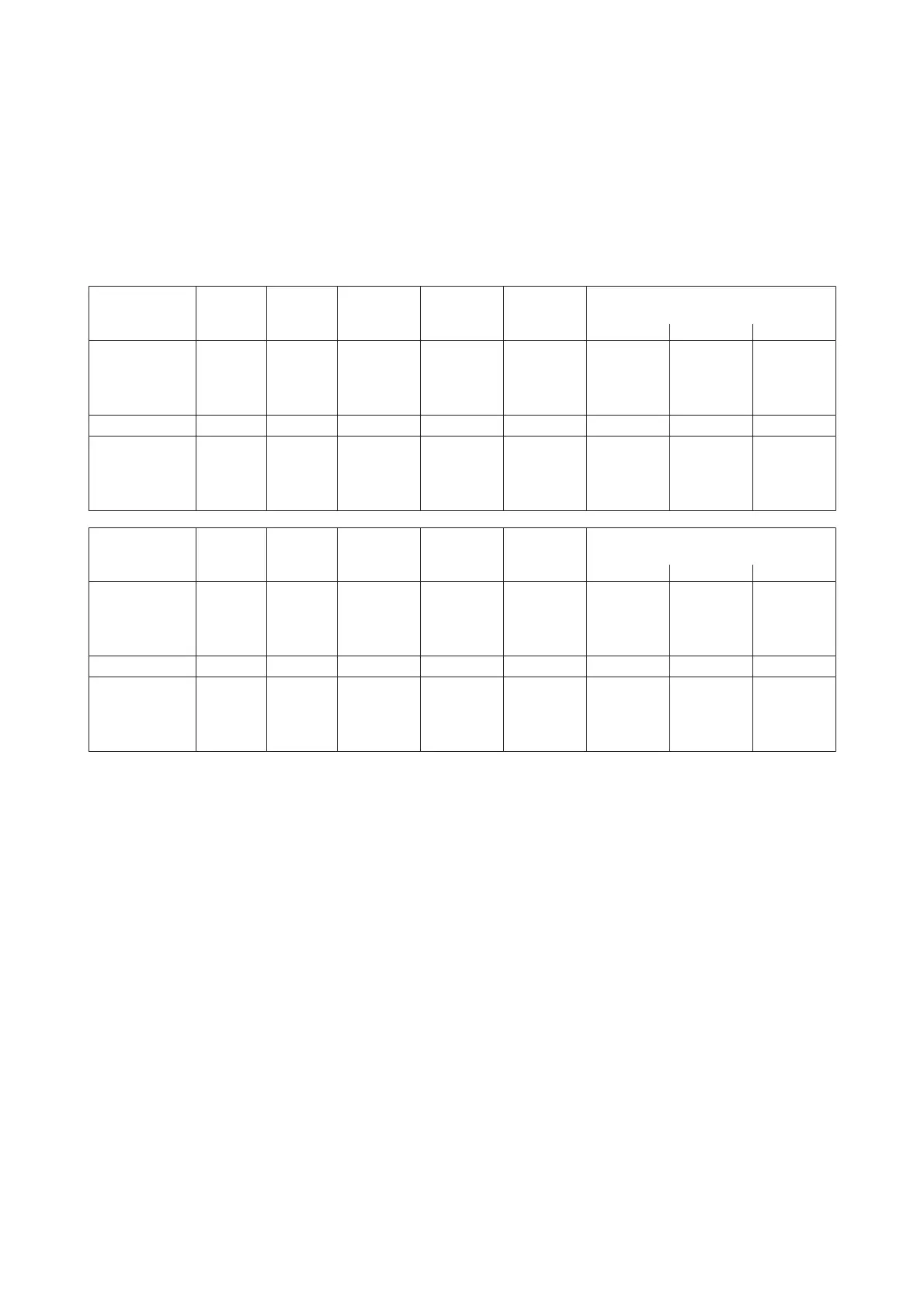

Model

P

n

[kW]

ED

[%]

I

a

/I

n

I

n

[A]

Fuse

(delayed-action)

[A]

Wire cross-section mm

2

for wire length

0 - 50 m 50 - 100 m 100 - 150 m

CPE F 16-8

CPE F 25-5

CPE F 32-4

CPE F 50-2

0,58/2,3 20/40 1,8/4,4 3,3/5,5 16* 1,5 2,5 2,5

CPE F 100-2 2 x 0,58/2,3 20/40 1,8/4,4 4,0/6,8 16* 2,5 2,5 —

CPE F 20-8

CPE F 30-5

CPE F 40-4

CPE F 75-1,6

0,7/2,8 15/25 1,8/4,4 4,0/6,8 16* 2,5 2,5 —

all data for 400 V, 3 Phases, 50 Hz – *for direct control, at independent control 10 A

Loading...

Loading...