34

©

2019 Columbus McKinnon Industrial Products GmbH

Attention: Maintenance work requires subsequent function testing with nominal load.

Daily Checks

• Visually check the pendant control switch and all cable for damage.

• Function check of the brakes (incl. triggering the EMERGENCY STOP button)

• Function check of the limit switches

• Function check of the overload circuit breaker

• Electric chain hoists with trolley:

• Check that the trolley runway is free from obstructions

• Check that the end stops on the trolley runway are fitted and secure.

Regular Inspections, Service And Testing

According to the existing national/international accident prevention or safety specifications, lifting units must be checked

• At least once per year by a competent person

• According to the risk assessment of the operating company,

• Before the initial start-up,

• Before restart following a shutdown

• After basic alterations. The concerned use conditions (e.g. operation in galvanizing facilities) can dictate shorter inspection intervals.

Repair work may only be carried out by a specialist workshop that uses original Yale spare parts. The inspection (mainly consisting of a

visual inspection and a function check) must determine that all safety devices are complete and fully operational and cover the condition

of the unit, suspension, equipment and supporting structure with regard to damage, wear, corrosion or any other alterations.

Initial operation and recurring inspections must be documented (e.g. in the CMCO works certificate of compliance).

If required by the trade association, the results of inspections and appropriate repairs must be verified.

If the hoist (from 1 t lifting weight) is fitted on or in a trolley, or if the hoist is used to move a lifted load in one or several directions, the

installation is considered to be a crane and the further inspections must be carried out, in accordance with DGUV Vorschrift 54 Cranes.

Paint damage should be touched up in order to avoid corrosion. All joints and sliding surfaces should be slightly lubricated. In case of

heavy contamination, the unit must be cleaned.

ATTENTION! Power supply must be disconnected while inspecting the device, unless the type of the examination excludes

this!

Maintanance of the load chain

The load chains are case-hardened and carry the designations 11 x 31 DAT.

The CPE/F electric hoists are specially designed to use this type of chain. For this reason only chains that have been approved by the

manufacturer may be used in these hoists.

Non-compliance with this specification will render the legal warranty or guarantee void of CMCO Industrial Products GmbH with

immediate effect.

Lubricating the load chain

The load chain must be lubricated before the first start-up and every month, however after 50 hours of operation at the latest. Under

some extreme conditions such as an increased dust effect or a particularly heavy-duty use, the intervals are to be shortened

appropriately.

The service life of the load chain can be increased through careful lubrication to 20-30 times compared with a chain that is not serviced.

• The chain must be cleaned before lubrication. Burning off is not permissible. Cleaning methods that do not deteriorate the chain

material are to be used (e.g. vapour degreasing, alkaline dip degreasing).

Cleaning methods that can cause hydrogen embrittlement, e.g. pickling or dipping in acid solutions, as well as surface treatments, which

can hide cracks or damages, are to be avoided.

• The chain must be lubricated in a tension-free condition so that a lubrication film can be formed at joints. This can happen e.g. through

dipping in oil.

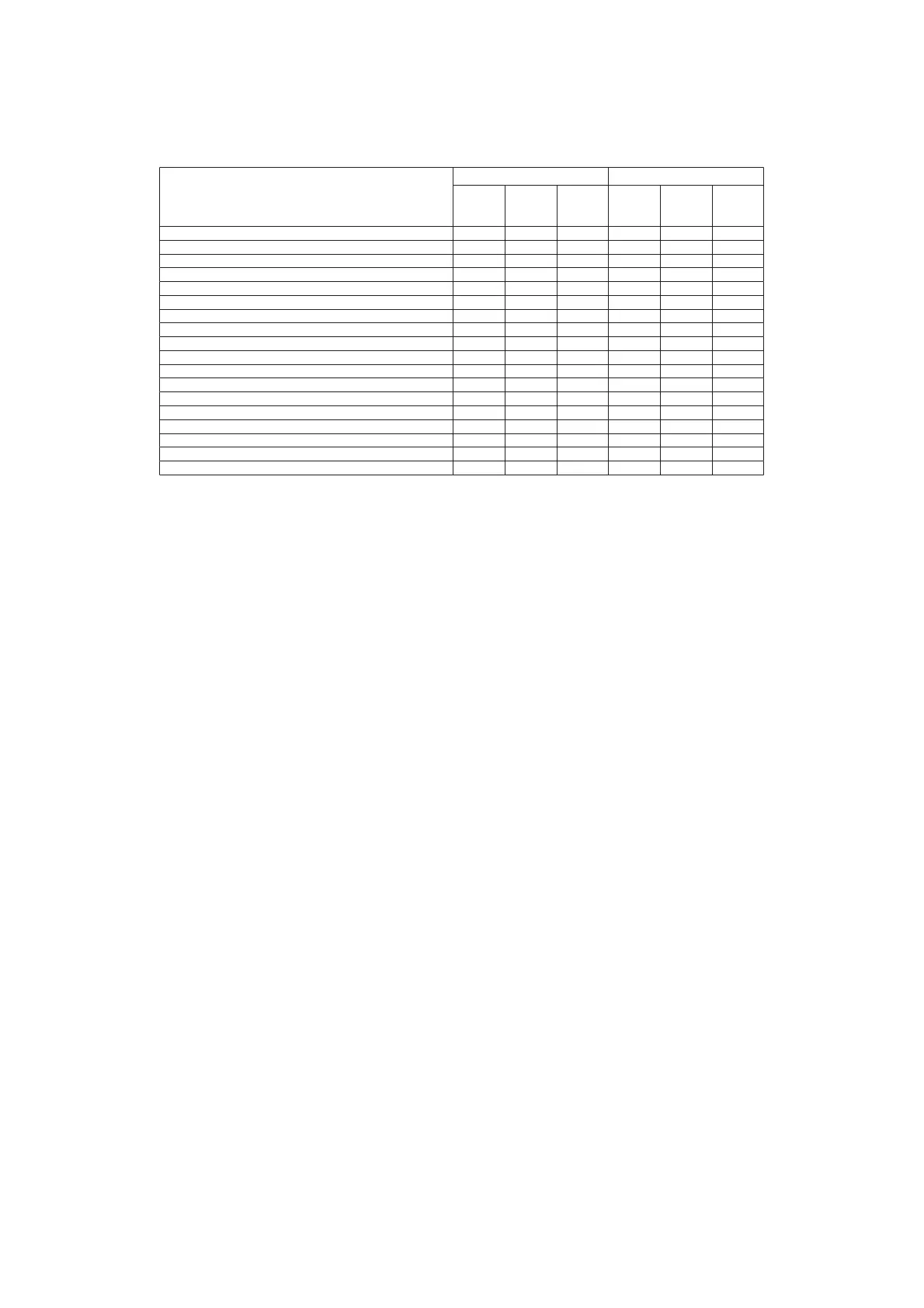

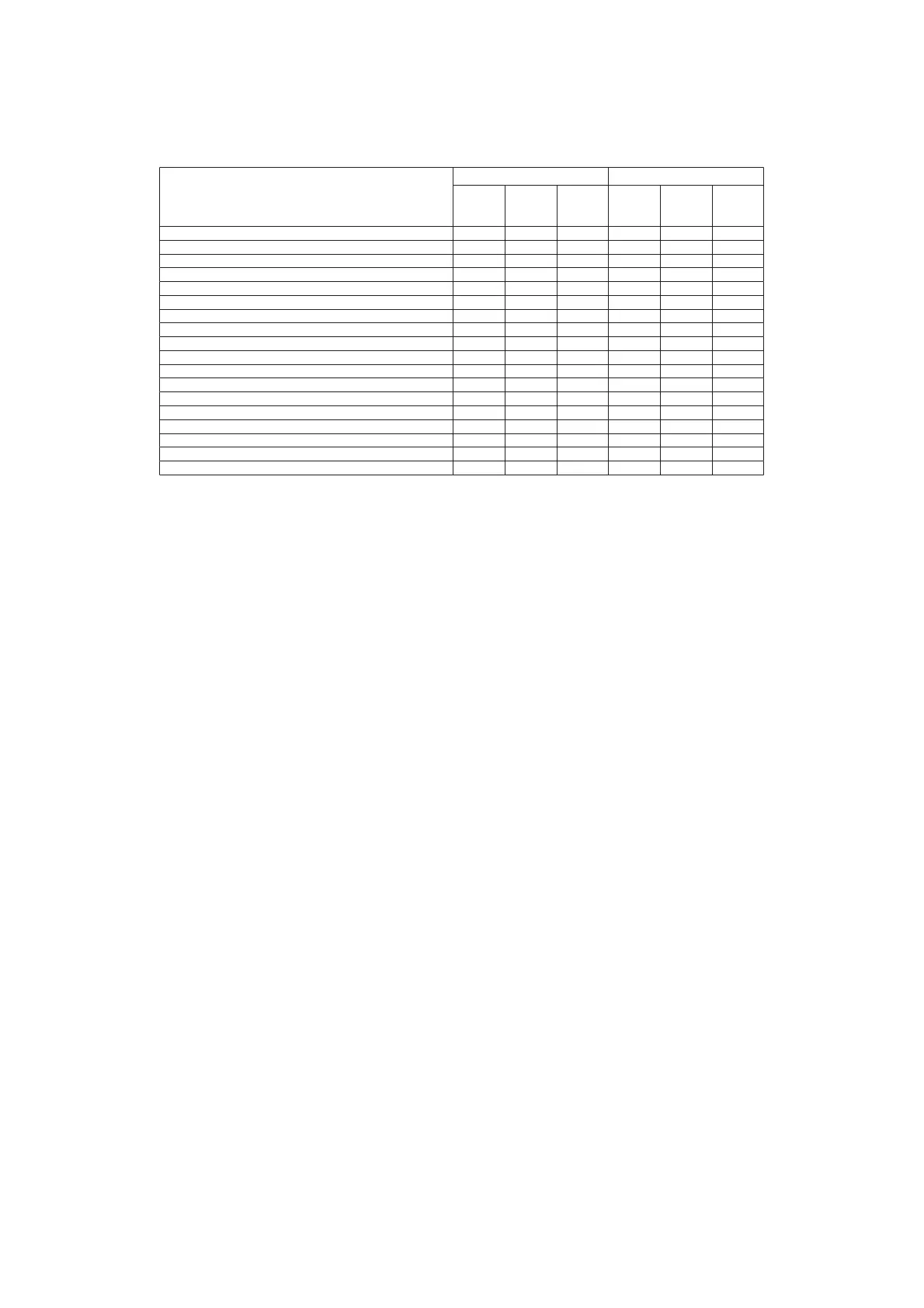

Inspection and Maintenance

Initial checks Periodical checks

during

commis-

sioning

after 50

operating

hours

after 200

operating

hours

daily

after 200

operating

hours

annually

Lubricate load chain • • • •

Pendant control and support wire • • •

Check oil level • • •

Function test of brake • •

Function test of end limit switch • •

Function test of overload device • •

Electrical installation and power supply • •

Check for wear in chain drive • • •

Inspect chain bolts for cracks • •

Inspect suspension bracket and load hook for cracks and deformation • •

Check screwed connections for tightness • •

Inspect trolley components for cracks and deformation • •

Oil change • •

Inspect motor and transmission of hoist •

Inspect motor and transmission of trolley •

Adjustment of overload device •

Adjustment of brake •

Lubricate geared trolley drive •

Loading...

Loading...