Chapter 7 Reduction and Reversing Gear

3. Inspection and Servicing

4LHA Seriei

3.

Inspection

and

Servicing

3-1

Clutch

case and

cover

(1)

Check

the clutch

case

and cover for cracking

with

a

test hammer.

Perform a color check when required.

If the

case

and cover are cracked, replace those together.

(2)

Check

for staining on the inside surface of the bearing

section.

Also,

measure the inside diameter of the

case

and cover.

Replace

the

case

and cover if these are worn beyond

the wear

limit.

3-2

Bearing

(1) Rusting and damage.

If the bearing is rusted or the taper roller retainer is

damaged,

replace the bearing.

(2) Make sure

that

the bearings

rotate

smoothly.

If

rotation

is not smooth, if there is any binding, or if any

abnormal sound is evident, replace the bearing.

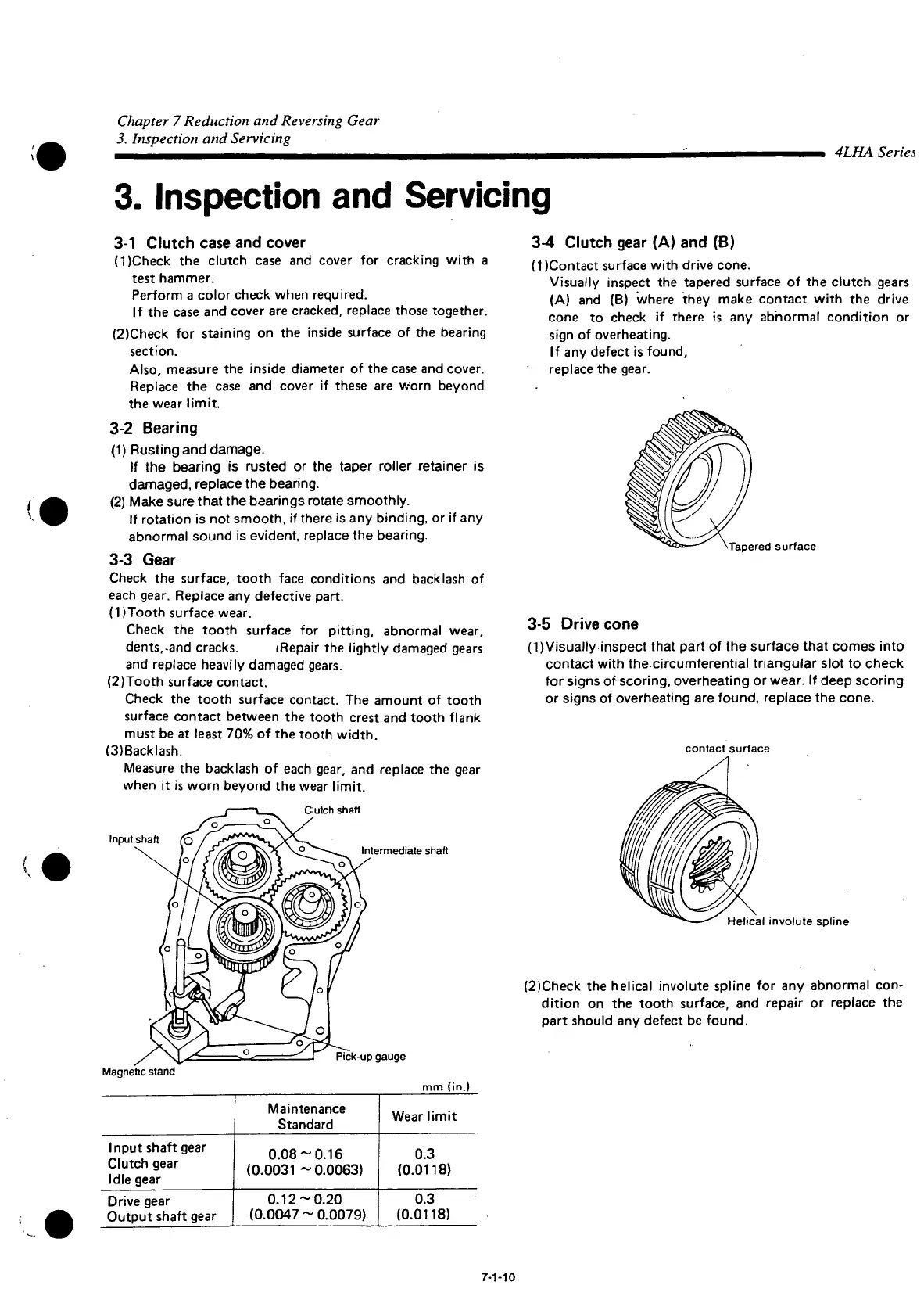

3-3

Gear

Check

the surface,

tooth

face conditions and backlash of

each

gear.

Replace

any defective

part.

(1

)Tooth surface wear.

Check

the

tooth

surface for pitting, abnormal wear,

dents,-and cracks. iRepair the

lightly

damaged gears

and replace heavily damaged gears.

(2) Tooth surface contact.

Check

the

tooth

surface contact. The amount of

tooth

surface contact between the

tooth

crest and

tooth

flank

must be at least 70% of the

tooth

width.

(3)

Backlash.

Measure

the backlash of each gear, and replace the gear

when it is worn beyond the wear

limit.

Clutch shaft

Input

shaft

Intermediate

shaft

Pick-up

gauge

Magnetic stand

mm (in.)

Maintenance

Standard

Wear

limit

Input

shaft gear

Clutch gear

Idle

gear

0.08-0.16

(0.0031

-0.0063)

0.3

(0.0118)

Drive gear

Output shaft gear

0.12-0.20

(0.0047 - 0.0079)

0.3

(0.0118)

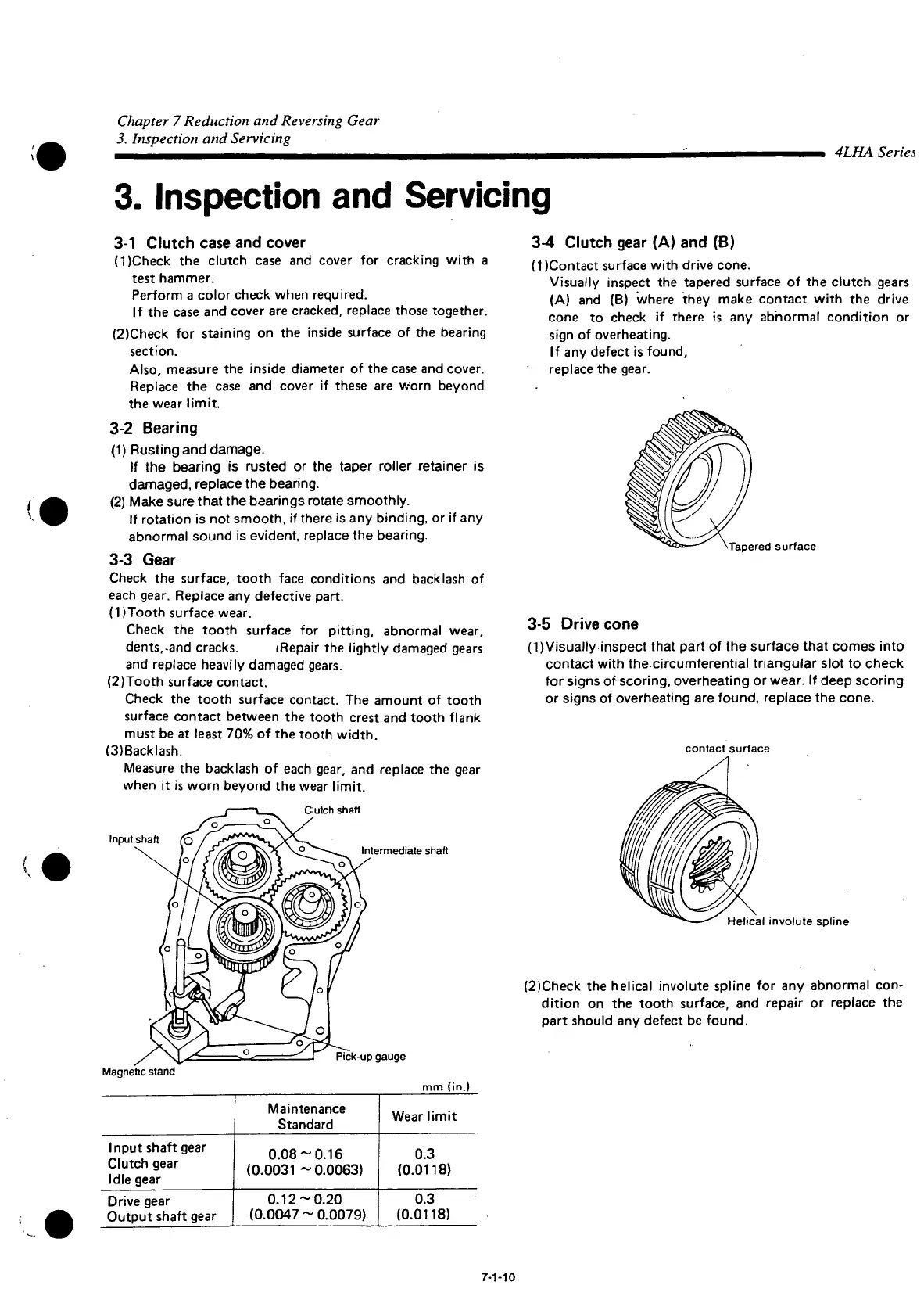

3-4

Clutch

gear

(A) and (B)

(1

(Contact surface

with

drive cone.

Visually

inspect the tapered surface of the clutch gears

(A) and (B) where they make contact

with

the drive

cone to check if there is any abnormal condition or

sign of overheating.

If any defect is found,

replace the gear.

Tapered surface

3-5

Drive

cone

(1)Visually inspect

that

part

of the surface

that

comes

into

contact

with

the circumferential triangular slot to check

for signs of scoring, overheating or wear. If deep scoring

or signs of overheating are found, replace the cone.

contact surface

Helical

involute spline

(2)Check the helical involute spline for any abnormal

con-

dition

on the

tooth

surface, and repair or replace the

part

should any defect be found.

7-1-10

Loading...

Loading...