Please

dispose

of

used

motor oil in

an

environmental friendly

way.

We

suggest you take

used

oil in a

sealed

container

to

your

local recycling center

or

service station

for

reclamation. Do

not

throw

it

in the trash; pour

it

on the ground;

or

down a drai

n.

3.

With

the

engine in a level position,

fill

to

the

outer

edge

of

the oil filler hole

with

the recommended oil.

Engine oil capacities: 16.9

oz.(O

.

SL)

Running

the

engine

with

a

low

oil

level can cause engine

damage.

The

Oil

Alert

system

(applicable

engine

types)

will

automatically stop

the

engine before

the

oil level falls below

the safe limit.

However,

to

avoid

the

inconvenience

of

an

unexpected

shutdown,

fill

to

the

upper

limit,

and check

the

oil

level

regularly.

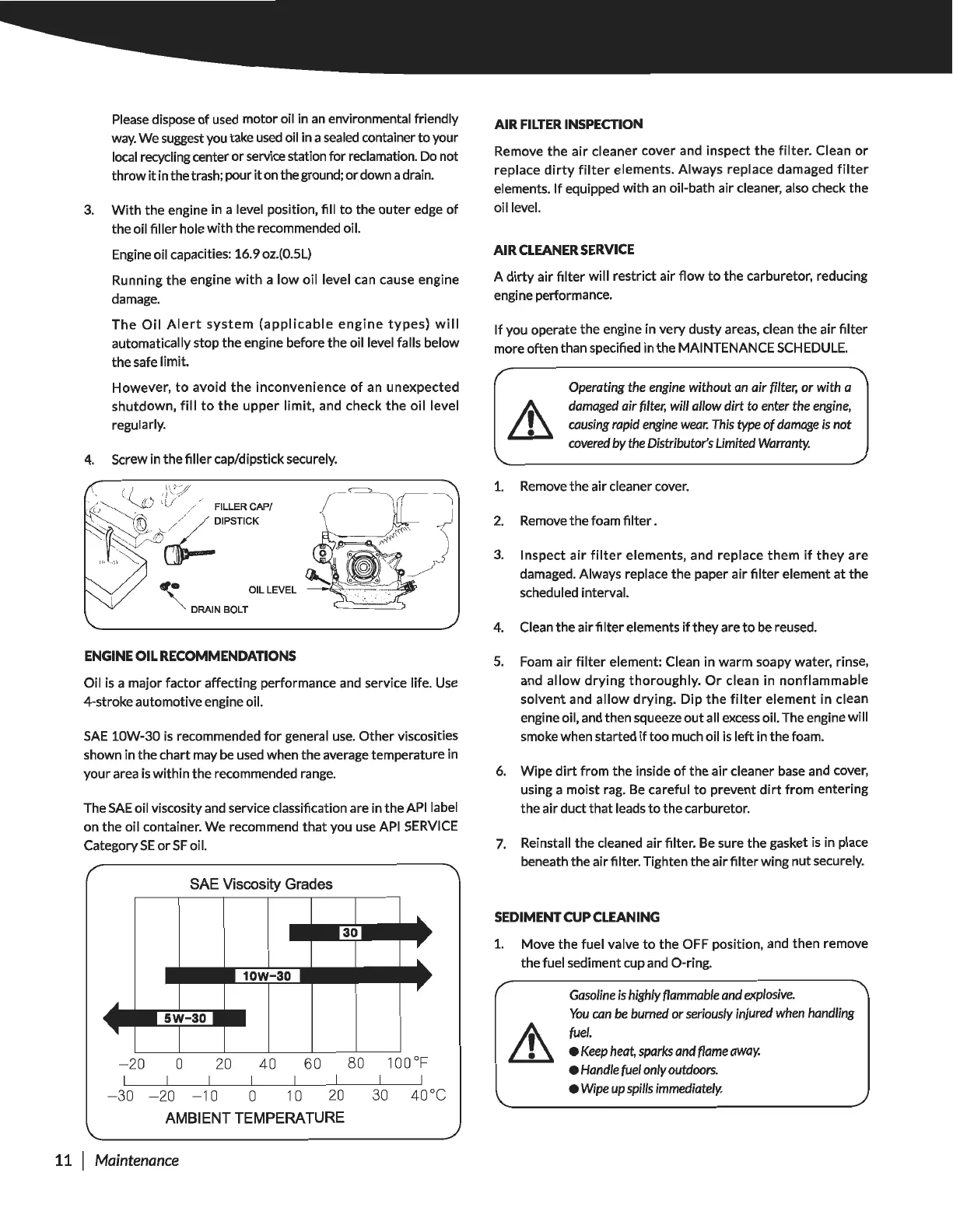

4. Screw in

the

filler cap/dipstick securely.

-

""

OIL

LEVEL

DRAIN BOLT

ENGINE

OIL RECOMMENDATIONS

Oil

is a major

factor

affecting performance and service life. Use

4-stroke automotive engine oil.

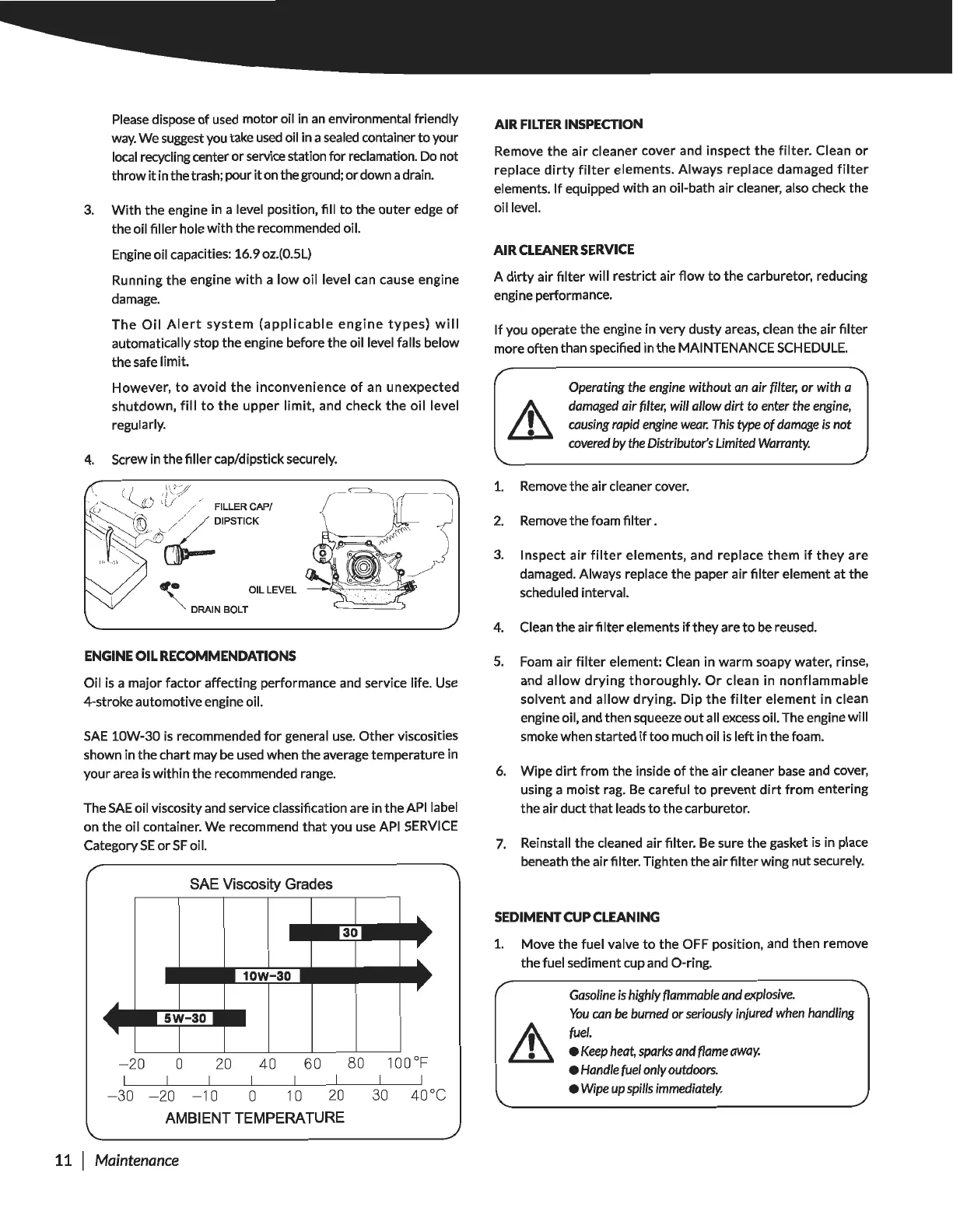

SAE

10W-30

is recommended

for

general

use.

Other

viscosities

shown in

the

chart may be used when the average temperature in

your

area

is

within

the

recommended range.

The

SAE

oil viscosity and service classification are in

the

API label

on

the

oil container.

We

recommend

that

you use API

SERVICE

Category

SE

or

SF

oil.

SAE Viscosity Grades

- 20

-1

0 0 1 0 20

AMBIENT TEMPERATURE

11

I Maintenance

AIR

FILTER

INSPECTION

Remove

the

air

cleaner cover and inspect

the

fi

lter. Clean

or

replace

dirty

filter

elements. Always replace damaged

filter

elements.

If

equipped

with

an oil-bath air cleaner, also check

the

oil

level.

AIR

CLEANER

SERVICE

A

dirty

air

filter

will

restrict air

flow

to

the

carburetor, reducing

engine performance.

If

you operate

the

engine in

very

dusty areas, clean

the

air

filter

more often than specified in

the

MAINTENANCE SCHEDULE.

Operating the

engine

without an air filter,

or

with a

damaged

air

filter,

will allow dirt

to

enter the

engine,

causing

rapid

engine

wear.

This

type

of

damage

is

not

covered

by

the

Distributor's Limited Warranty.

1. Remove

the

air cleaner cover.

2. Remove

the

foam

filter.

3.

Inspect

air

fi

lter

elements, and replace

them

if

they

are

damaged. Always replace

the

paper air

filter

element at

the

scheduled interval.

4. Clean

the

air

filter

elements

if

they

are

to

be reused.

5. Foam

air

filter

element: Clean in

warm

soapy

water

, rinse,

and

allow

drying

thoroughly.

Or

clean

in

nonflammable

solvent

and

allow

drying.

Dip

the

fi

l

ter

element

in clean

engine oil,

and

then squeeze

out

all

excess

oil. The engine

will

smoke when started if

too

much oil is

left

in the foam.

6.

Wipe

dirt

from

the

inside

of

the

air

cleaner base and cover,

using a moi

st

rag. Be careful

to

prevent

dirt

from

entering

the

air

duct

that

leads

to

the

carburetor.

7. Reinstall

the

cleaned air filter. Be sure the gasket is in place

beneath

the

air filter. Tighten

the

air

filter

wing

nut

securely.

SEDIMENT

CUP

CLEANING

1. Move

the

fuel valve

to

the

OFF position, and

then

remove

the fuel sediment cup

and

0-ring.

Gasoline

is highly

flammable

and

explos

i

ve

.

You

can

be

burned

or

seriously

injured

when

handling

fuel

.

•

Keep

heat,

sparks

and

flame

away.

•

Handle

fuel

only

outdoors

.

e

Wipe

up

spills

immediately.

Loading...

Loading...