Abacus Lighting, Sutton-in-Ashfield, Nottinghamshire, NG17 5FT, England. Tel: (+44) 01623 511111, www.abacuslighting.com

17

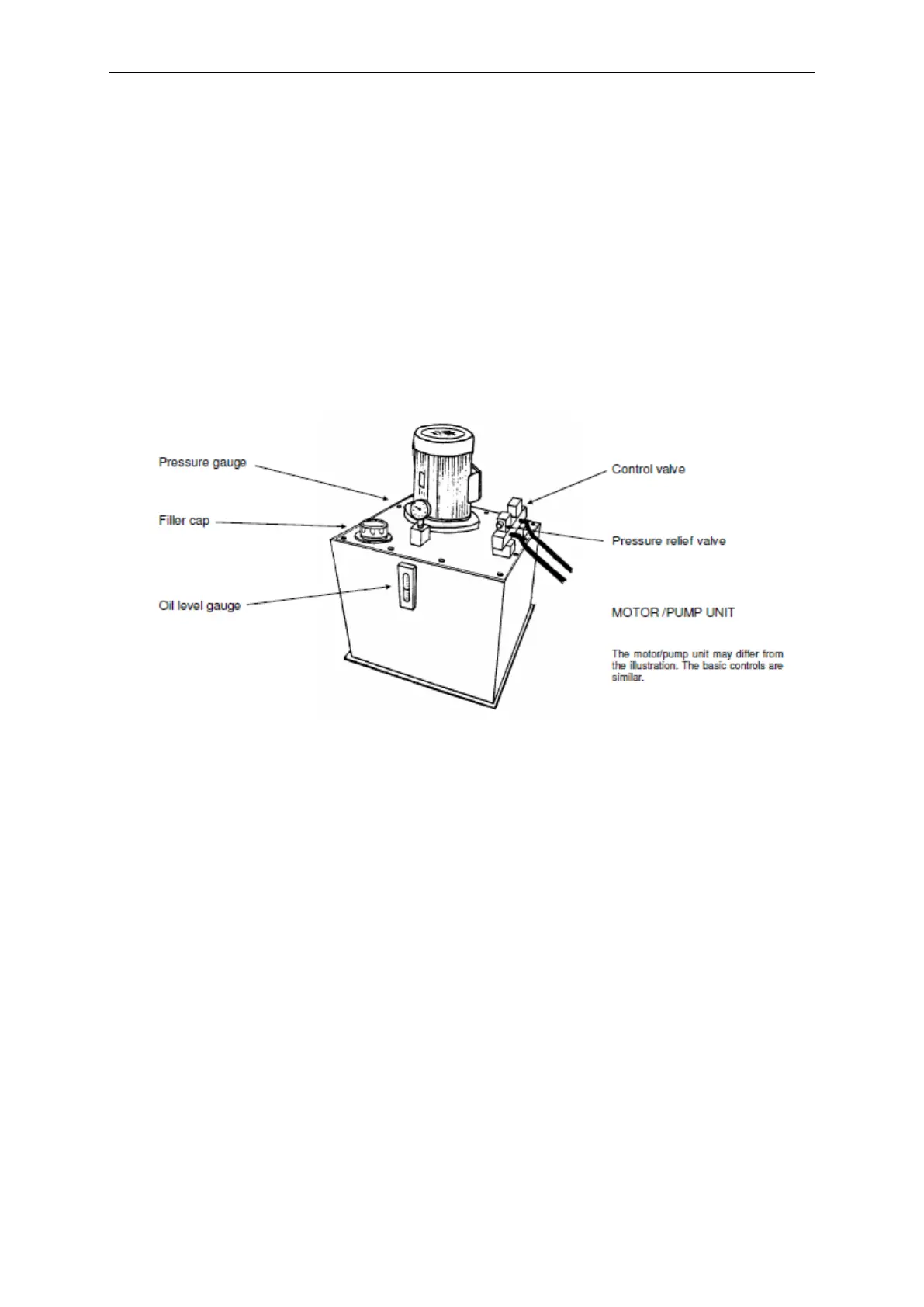

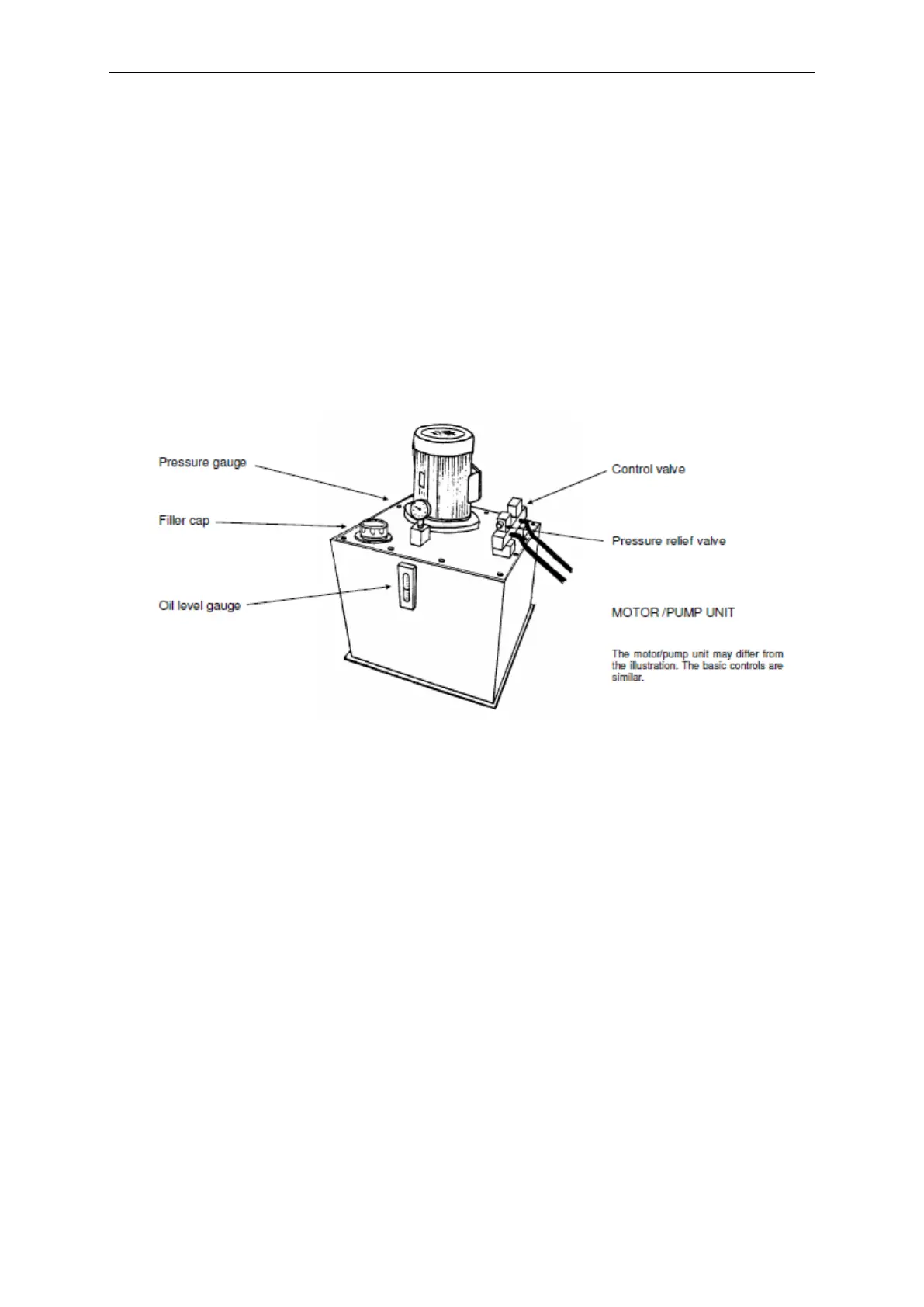

Check the oil level in the tank and top up if necessary. This should be carried out with the tank as

near horizontal as possible and with the ram fully closed. The oil level should be to the centre of

the clear indicator panel on the tank side or to the level mark if one is provided. Note that if the

oil level is topped up with the ram extended, oil may be expelled from the filler cap during

lowering of the mast.

Examine the hydraulic hoses that link the ram to the pump unit control block and ensure that the

couplings and connections are firm, intact and free from leaks. Refer to 4.4 for detailed

information on hose inspection and replacement.

Check that the electrical flex and plug for damage and then connect it to the mains, ensuring the

correct voltage is being used. Check that the electric motor is running by operating the control

valve to extend the ram a short distance. Operate the control lever to retract the ram. Both

movements up and down should be smooth and jerk free.

Before attempting any work on the flow control valve ensure the ram is fully closed and supported

in the vertical position, with the flow control valve uppermost. Switch off the electric motor and

operate the flow control valve back and forth several times to depressurise the hydraulic circuit.

Clean the area around the large plug. Removing it will expose the spring and valve poppet. Check

that the micro filter inside the valve poppet is present and remove.

Clean and dry all components and check that the orifice (0.7mm bore) is unobstructed. Check

that the filter has not collapsed due to heavy contamination. Carefully reassemble the

components paying particular attention to cleanliness. Replace the bonded seal and plug and

tighten securely.

CAUTIONARY NOTE: THE RAM IS A SIGNIFICANT WEIGHT (see table above). ENSURE THE

CORRECT MANUAL HANDLING TECHNIQUES ARE USED AT ALL TIMES WHEN LIFTING

OR MOVING THE RAM.

The hydraulic ram can, if necessary be bled to remove any air that has entered the system. To do

this requires the ram to be removed from the trolley and laid horizontally with the flow control

valve blocks uppermost (see cautionary note above). The procedure is as follows;

• Slightly raise the top end of the ram and fully extend the piston.

Loading...

Loading...