Trouble-shooting

3. Complete Cleaning and Maintenance: remove and clean parts and assemblies periodically. Desired

results are achieved only by cleaning after removal.

Steps for Disassembling Components:

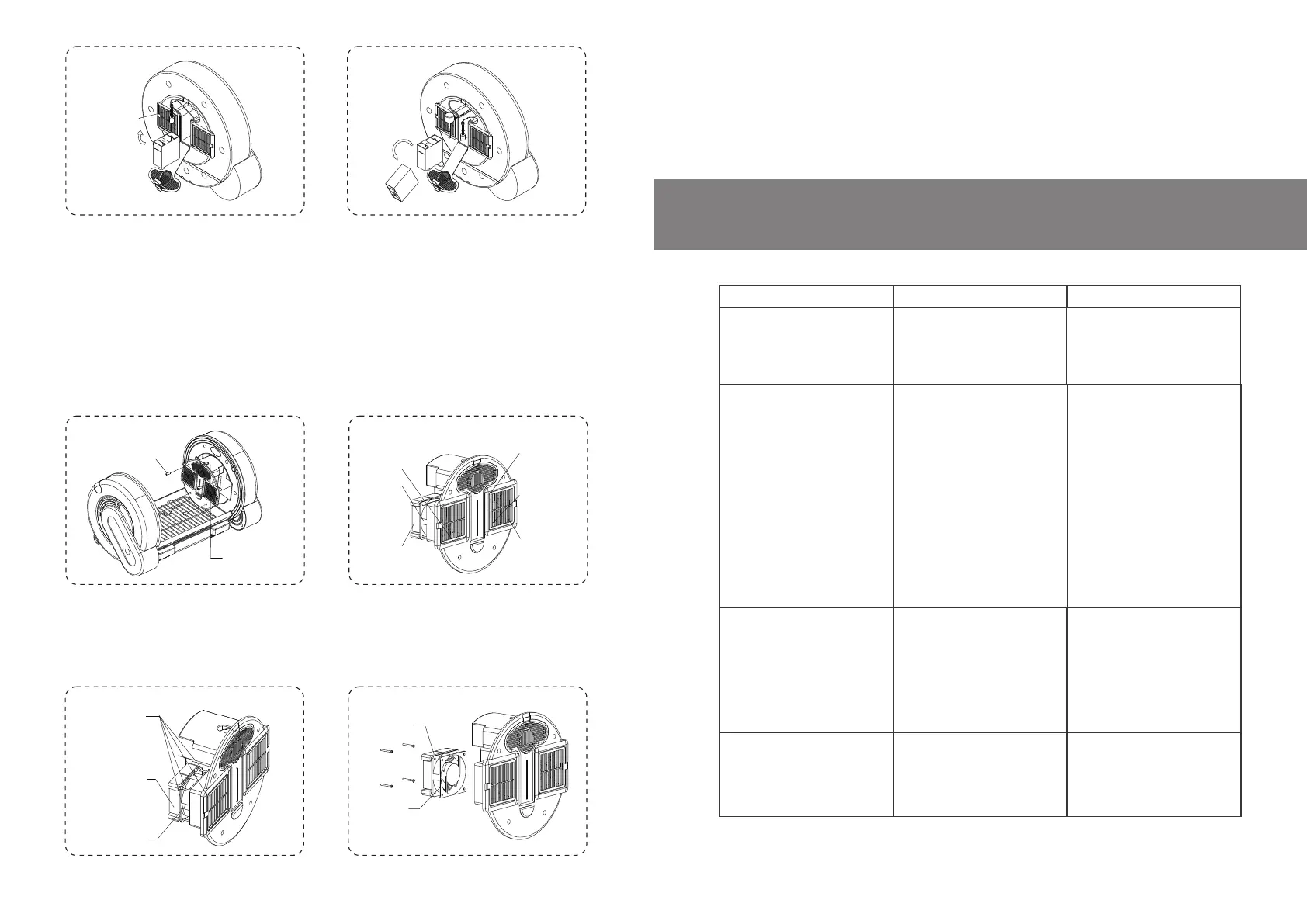

Remove four screws from the master control rack on the right to take down the right master control rack,

(remove the left master control rack in the same way). See figure. 8.3.1.

Remove power connection plugs on power cords on one side of the master control rack one by one. Note

that plugs have different colors for each electrical component.

Warning: do not remove control racks or electrical components from control racks immediately after shut

down; give it some time to cool down. The heaters in control racks reach high temperature. Remove control

racks or contact heaters after a 30 minutes respite after shutdown.

Remove and clean filters behind the square plastic section inside the chamber.

4. Cleaning

The ICU must be empty at the time of cleaning. Cleaning is feasible only after removal.

5. Maintenance

It is suggested to maintain the machine every two months during normal operation, which shall be carried

out in accordance with removal, installation and maintenance procedures above.

16 17

No atomizing form the

atomizer

1.Water shortage of the

water tank of the atomizer

2.Damaged ultrasnic chip of

the atomizer

3.Water scale in the tank of

the atomizer

Remaining solution not atomized

in the cup after atomization of the

medical atomizer

Atomizing time and volume

depend on concentration of

atomizing liquid

Repeat the atomization

operation procedure if not

completely atomized once

1.Add water into the water tank

until it is at the same level of

the cup bottom

2.Replace the ultrasonic chip

3.Gently scrub the inside of

the tank with lint

After the power switch is pressed,

there is no reaction or the power

indicator lamp is still off

Phenomenon

1.Bad power connection and

plug connection

2.Damaged switch

Cause analysis Solution

1. Check power connection

2.Replace the power switch

Little atomizing volume form the

medical atomizer

1.Too big atmizing particles of

solution causes little atomizing

volume

2.Solution contains syrup or

colloform

3.Tablets are used for

dissolution

4.Oily impurities on the surface

of solution

1.Too big particles are not

suitable for operation of this

atomizer

2.When solution contains syrup

or colloform,it requires with dry

filter paper

3.When tablets are used for

dissolution,dissolve sediments

to remove impurites first

4.Remove oily impurities on the

surface of solution with clean

tissue firstivvv

Sensor

Figure 8.3.3-c Figure 8.3.3-d

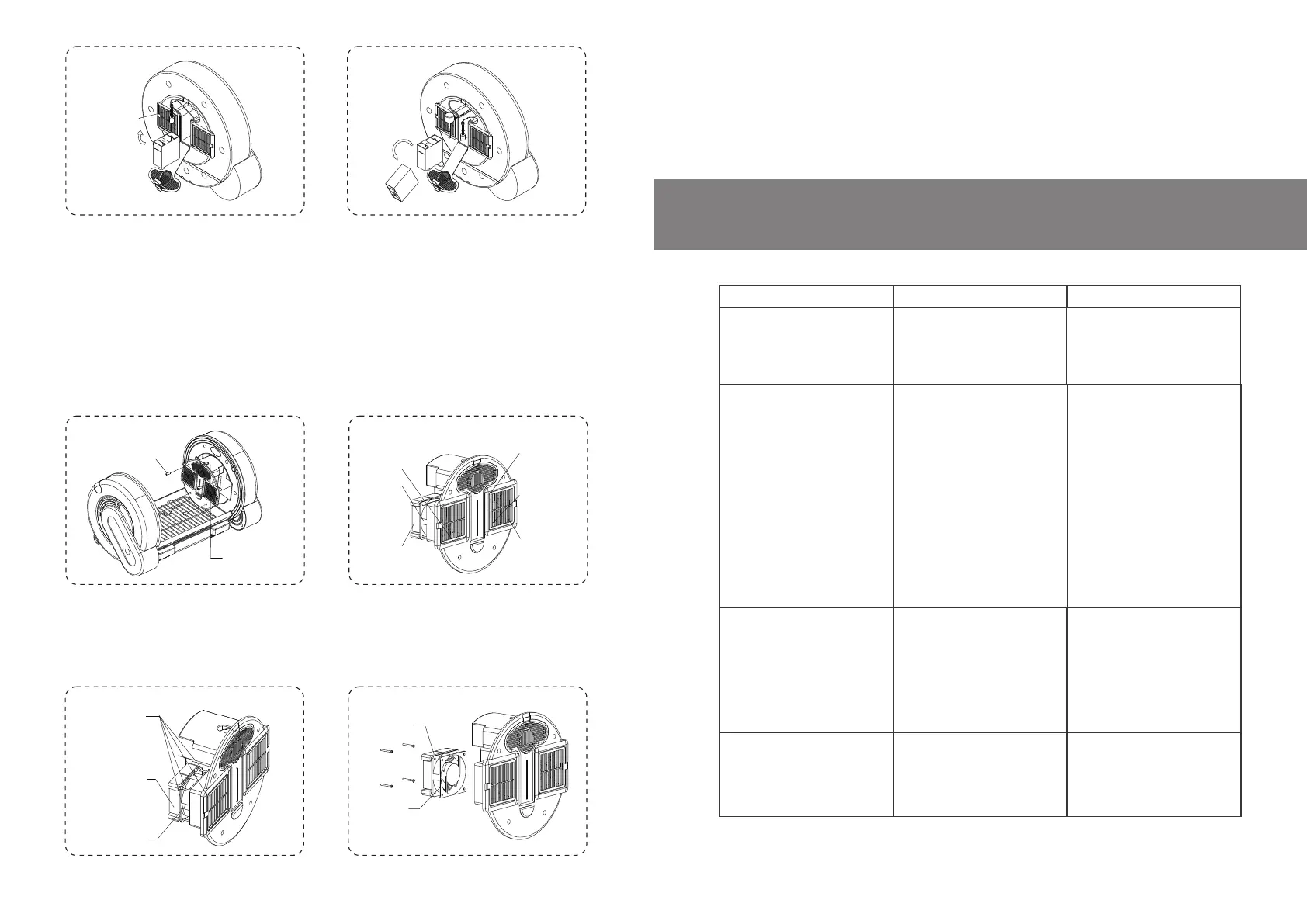

Remove four screws in the fan box and take out the whole heater. Clean the fan. Try not to remove heat sinks

from the fan, especially PTC heater bands that cannot be removed from heat sinks. See figure. 8.3.2.

Figure 8.3.1-b

Figure 8.3.1-a

Temperature

Humidity sensor

PTC Heater

Fan

Fan

PTC Heater

PTC Heater

screws of fan

Figure 8.3.2-a

Figure 8.3.2-b

Loading...

Loading...