ler operation, and is necessary only

when initially programming the basic

parameters.

Microprocessor

− Multilingual

menu

− Phase sequence control

− Independent control of individual

compressors

− Ammetric transformer

− Cumulative failure block signalling

− Alarm log function

− Daily/weekly programming

− Inlet/outlet water temperature

display

− Alarm display

− Full proportional regulation of the

output water temperature

− Programmable timer function

− Interfaceability with the Modbus

protocol (accessory)

− Control and management of

pump/s rotation

− Compressor rotation control

− Analogue input from 4 to 20 mA

− “Always Working” function. In case

of critical conditions the machine

does not arrest but is able to self-

adjust itself and provide maximum

output power in those conditions

− Self adapting operating differen-

tial “Switching Histeresys” to ensure

correct compressor operation at all

times even in plants with a low wa-

ter content or insufficient flow rates.

This system reduces the compressor

wear

− The PDC “Pull Down Control” sys-

tem to prevent the activation of

the power steps when the water

temperature is approaching the

set point quickly. It optimises the op-

eration of the machine both when

running normally or when there are

load variations, thereby assuring

top machine efficiency in all situa-

tions.

For further information, refer to the user

manual.

HYDRAULIC CIRCUIT KEY

1 Condenser

2 Evaporator (plate-type exchangers)

3 Flow switch

4 Filter

5 Pump

6 Expansion tank

NB

The Victaulic joints and the soldering

studs for the condenser and evaporator

are provided

1

3

2

4

5

6

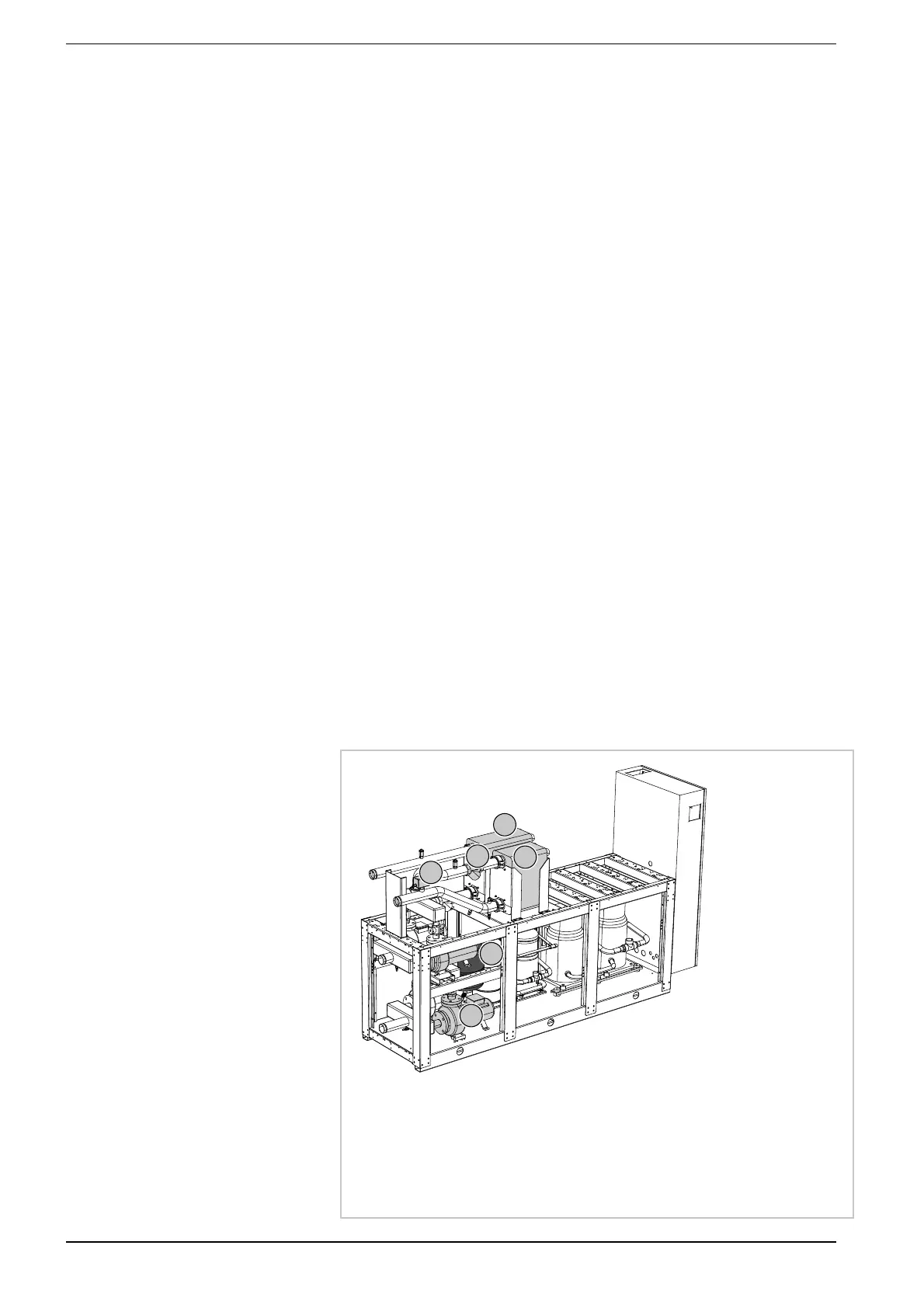

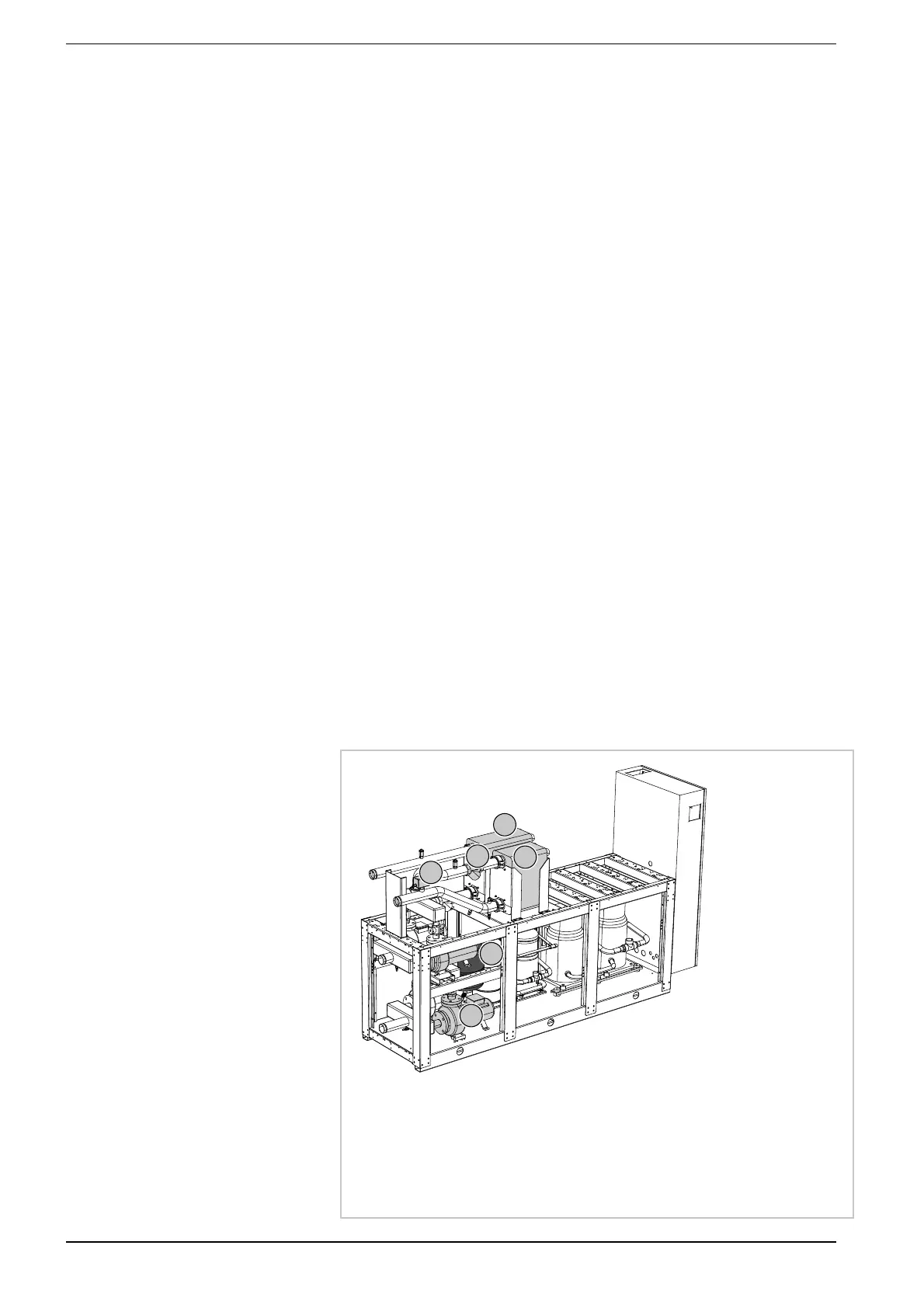

Example of NXW version [°]

10

INXWPY. 1004. 4438805_00

Loading...

Loading...