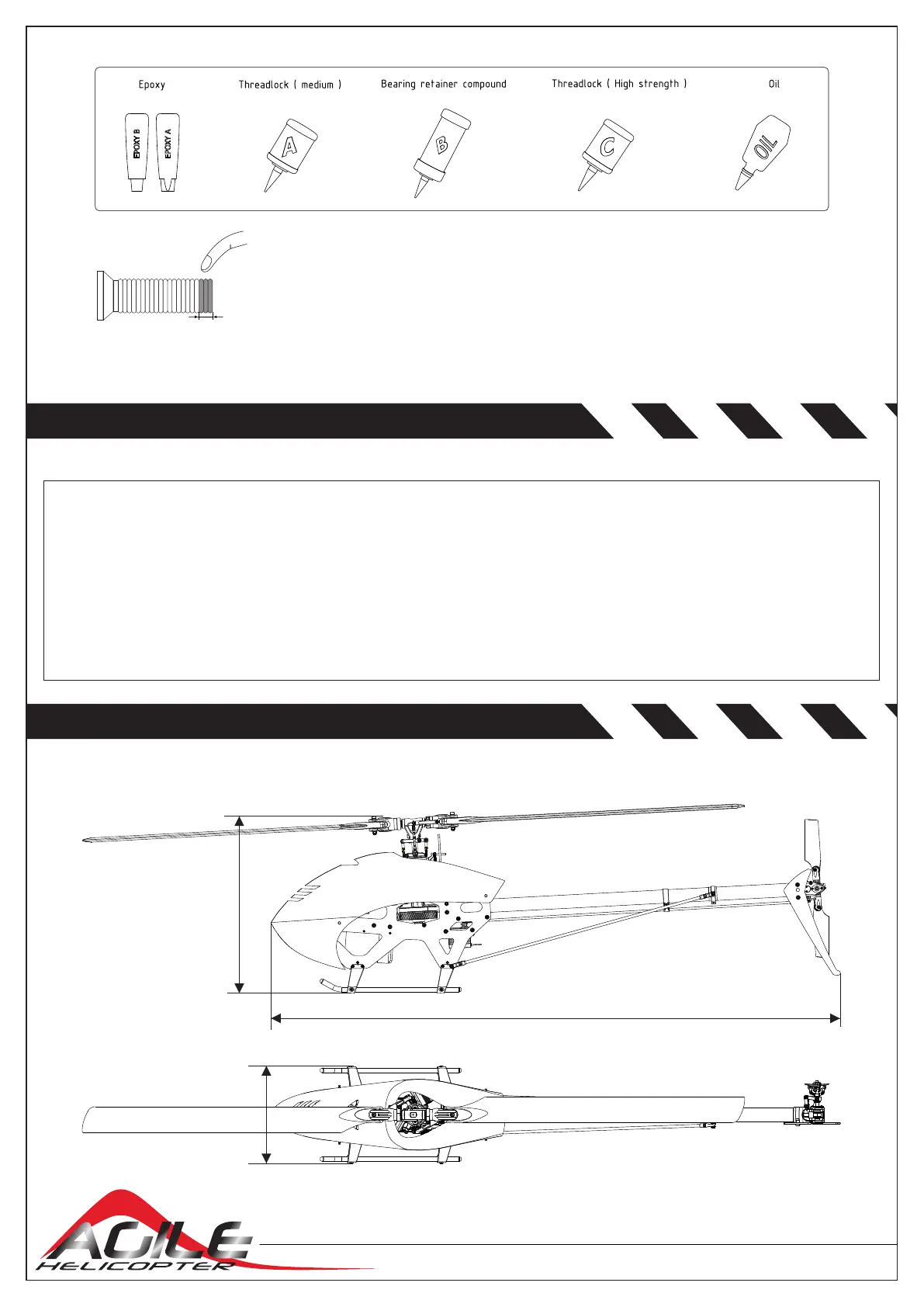

5.Equipment Required for Assembly

RADIO TRANSMITTER AND ELECTRONIC EQUIPMENT REQUIRED FOR ASSEMBLY

•Brushless electric motor: 6s Lipo - 1200KV

(4mm Bolt holes, 30mm mount width, 6mm * 37mm motor shaft)

•Speed controller: minimum 120A

(ESC specs limits should be rated accordingly to the maximum amps handling by the motor)

•Lipo Batteries: 6s 5000-5500 mAh

•Electronic flybarless system

•3 pcs Metal standard servo's / 3 pcs Metal medium sized servo's

•1 tail rotor servo, standard size, high speed required

•550 mm main rotor blades

•92 mm tail rotor blades(included)

•6 channel or more helicopter transmitter system, 2.4 Ghz frequency preferred

•Receiver 6 channel or more (working with your transmitter specs)

“A” Glue width: approx. 2mm

2mm

“OIL” Lubrication grease. “A” thread lock, apply a small amount on screws or metal parts and wipe surplus off. When

disassembling, recommend to heat the metal joint about 15 seconds. (NOTE: Keep plastic parts away from heat.)

When you see the marks as below, please use glue or grease to ensure flying safety.

Page 05

Agile 系列直升机商标为欧洲Flight Research RC 所持有,由深圳KDS模型荣誉生产。

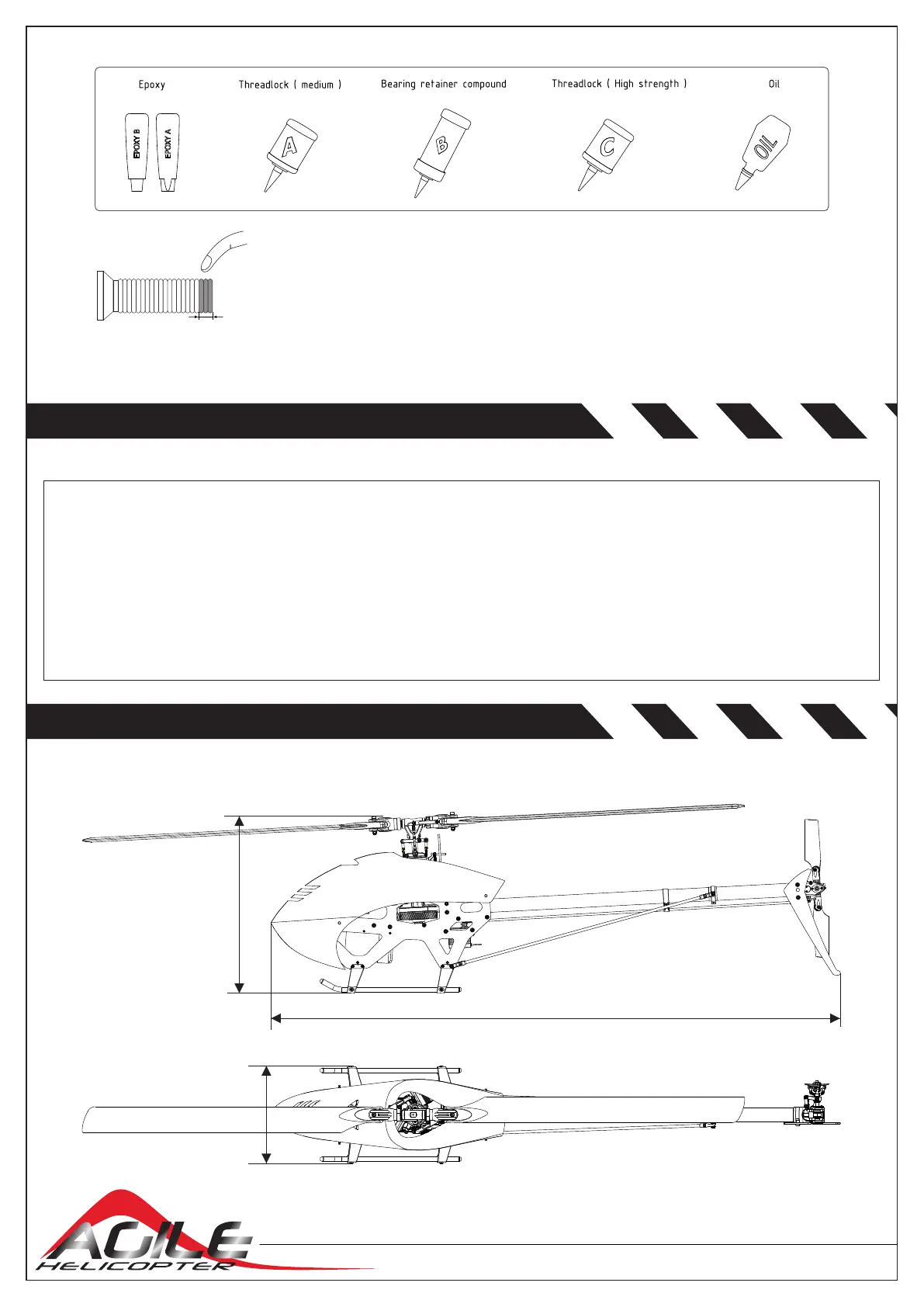

6.Specification

1065mm

330mm

182mm

Loading...

Loading...