Chapter 2 57

Installation and Setup

Calibrating System Components

Measurement Procedure Using a N5532A/B Sensor Module

Step 1. Connect, configure, and verify the measurement system. See “System Hardware

Connections” on page 44 and “System Configuration” on page 47.

Step 2. Calibrate the power meter. See “Zero and Calibrate the Power Meter” on page 53.

Step 3. Connect the sensor module to the signal source and assure proper connector care

and connector torque settings are followed. SMA/ 3.5mm connectors should

receive 8 inch-pounds of torque and Type N connectors 12 in-pounds.

Step 4. On the PSA, perform the Auto Align routine by pressing

System, Alignments, Align

All Now

.

Step 5. Set the signal source amplitude and frequency. For this example use 0 dBm and 50

MHz. Do not change any settings during this procedure.

Step 6. Configure the PSA settings as follows:

NOTE Range 3 Switch Delay (Early instruments only)

Applies only to instruments with Option Driver part number E444060253 and

firmware release less than A.11.00. Press

System, More, Show Hardware to view

the option driver part number.

When range 3 is entered, several internal PSA settings are changed including

enabling the optional preamp and decreasing input attenuation. For optimum

accuracy, a delay of five minutes is initiated when this function is ON. The delay

allows the preamplifier to stabilize. Assure the Range 3 Switch Delay is On for

both the Range Calibration and the TRFL measurement process since you may

perform the Range Calibration as a separate routine.

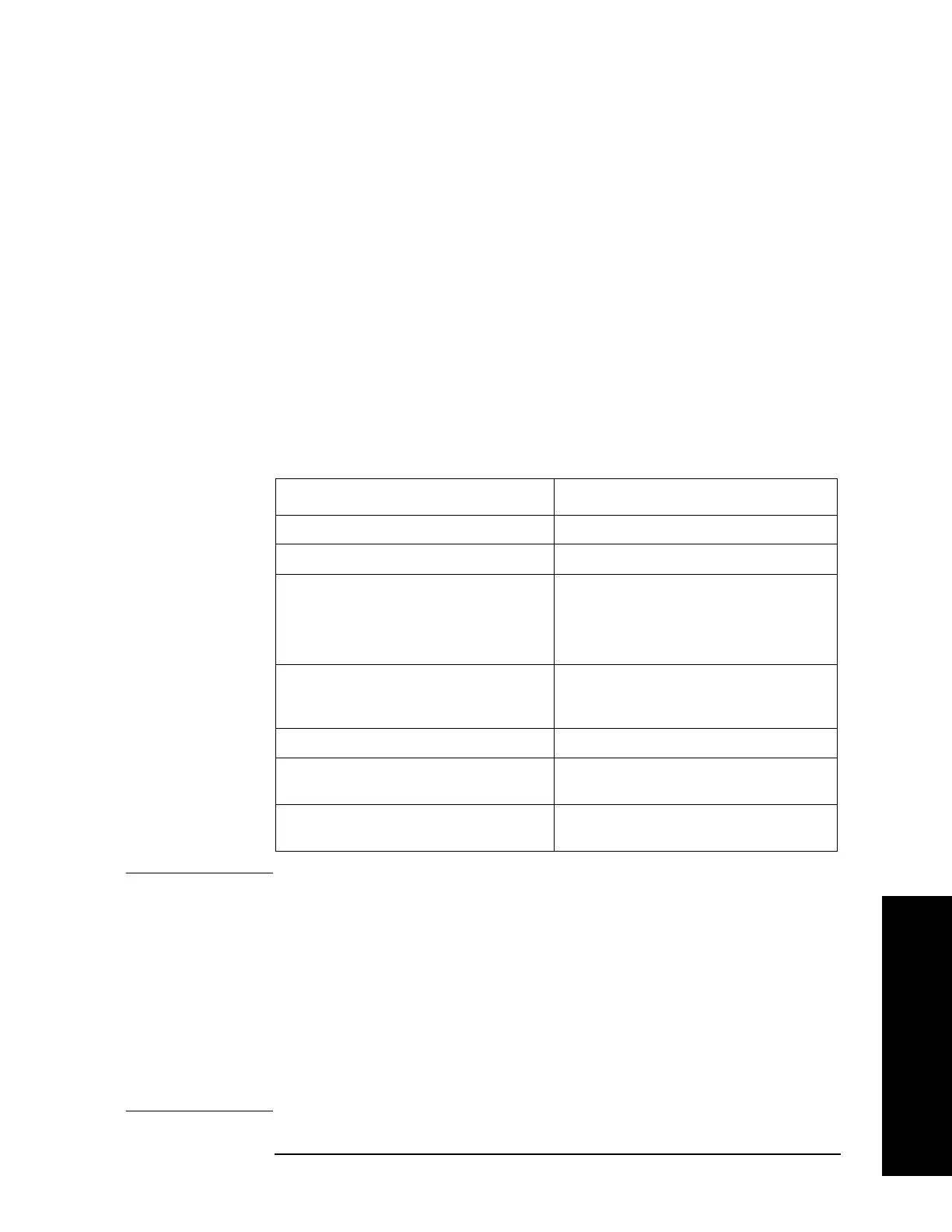

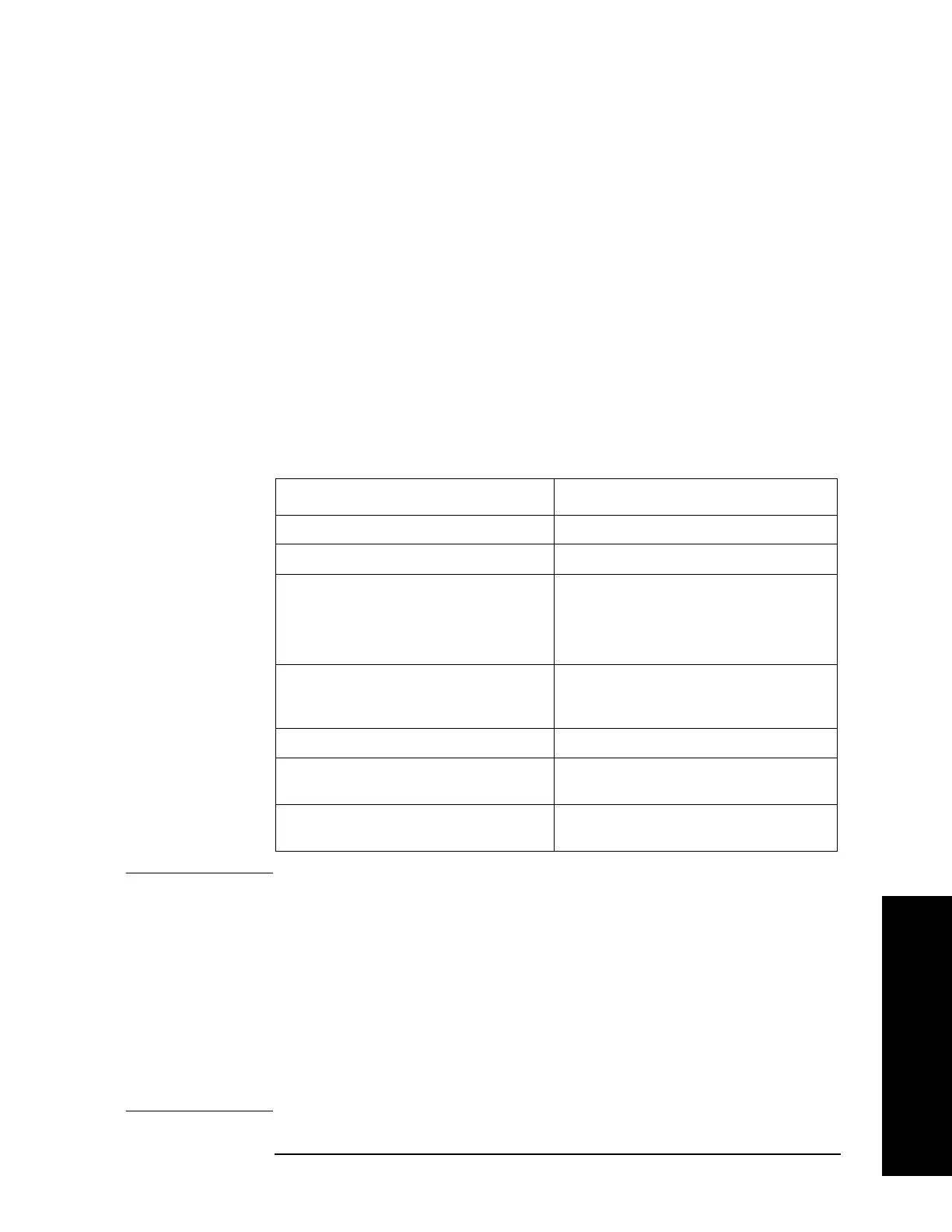

Table 2-6 PSA Settings

Parameter Setting

Mode Measuring Receiver

Measure Tuned RF Level

Frequency

Note: Do not use the Frequency Counter

function. You must press the Frequency key

and set the frequency manually.

Same as signal source frequency

Range 3 Switch Delay

(Under Meas Setup, More)

See note below

May choose On or Off.

Default is Off

Range Switching Default is Auto

10 MHz Out

(Under System, Reference)

ON

Freq Ref

(Under System, Reference)

Int

Loading...

Loading...