9

CHECK FOR LOOSE FASTENERS

1. Beforeeachusemakeathoroughvisualcheckofthe

spreaderforanyboltsandnutswhichmayhaveloosened.

Retightenanylooseboltsandnuts.

CHECK FOR WORN OF DAMAGED PARTS

2. Check for worn or damaged parts before each use.

Repairorreplacepartsifnecessary.

CHECK TIRE INFLATION

3. Checkiftiresareadequatelyinatedbeforeeachuse.Do

notinatebeyondmaximumrecommendedpressure.

FIGURE 15

1. Rinseinsideofhopperandexteriorofspreaderanddry

offbeforestoring.

2. Storeinaclean,dryarea.

CLEANING

4. Rinseinsideofhopperandexteriorofspreaderanddry

offbeforestoring.

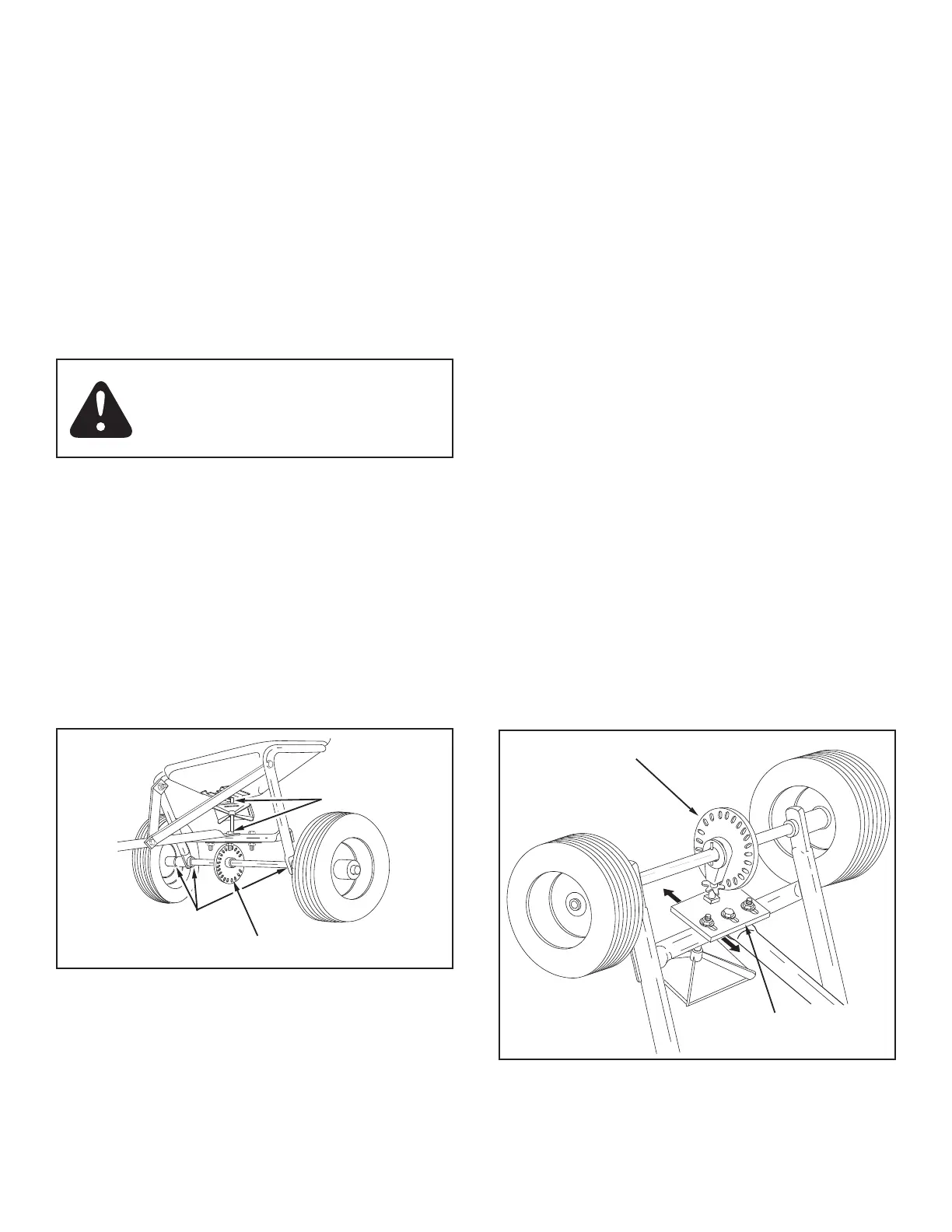

LUBRICATE (Seegure15.)

5. Lightly apply automotive grease as needed to the

sprocketandgear.

6. Oil the nylonbushings on the vertical sprocket shaft

andontheaxleatleastonceayear,ormoreoftenas

needed.

7. Oilrighthand(idler)wheelbearingatleastonceayear

ormoreoftenasneeded.

MAINTENANCE

STORAGE

CAUTION: DO NOT inatetiresbeyondthe

maximumrecommendedpressureprinted

onsideoftire.

REPLACING SLOTTED GEAR

1. If the axle, slotted gear and sprocket assembly is

disassembled,markdownthepositionsofthepartsas

theyareremoved.Thedrivewheelandsprocketpositions

inrelationtotheslottedgeardeterminewhichdirection

thespreaderplatewillspin.Besuretoreassemblethem

intheiroriginalpositions.(Refertogure4onpage5.)

Useshimwashers(Ref.no.21onpages10and11)

asneededforminimumbacklash.Addgreasetogear

andsprocket.

SERVICE AND ADJUSTMENTS

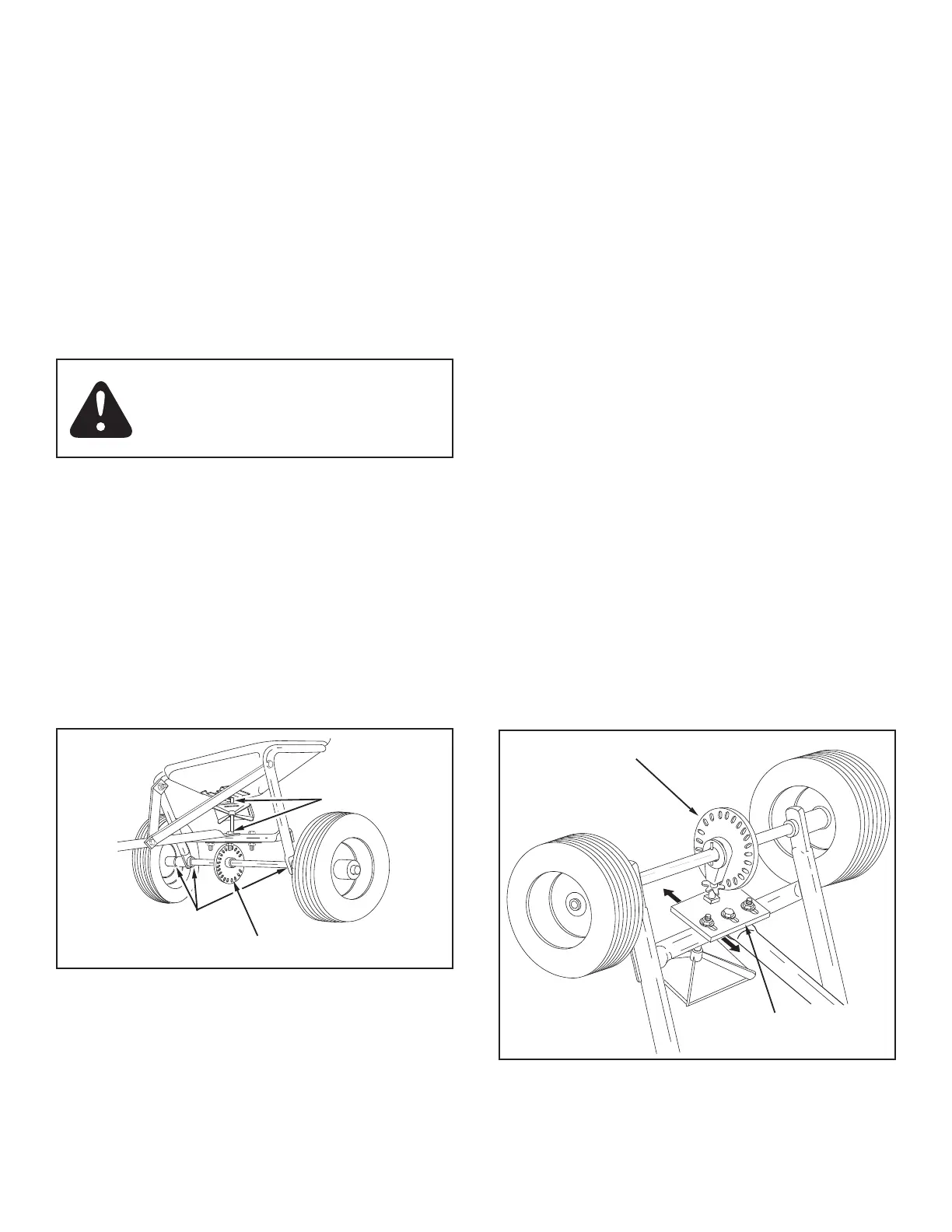

SHAFT SUPPORT PLATE

SLOTTED GEAR

IF THE SPREADER LOCKS UP

1. Turnthespreaderoversothatthewheelsareoffthe

ground.

2. Loosenallthreenutsontheshaftsupportplatejust

enoughsothattheboltscanbeturnedeasilywitha

wrenchbutcannotbeturnedbyhand.

3. Spinthedrivewheelandnotehowfreelyitspinsand

howmuchnoisetheslottedgearmakes.

4. Tofreeupthewheelandgear,tapgentlyonthefront

orrearedgeoftheshaftsupportplatetomoveit

slightlyforwardorbackward.Youcanalsotapatthe

cornersoftheplatetoangleitslightly.

5. Spinthedrivewheelaftereachadjustmenttoseeifit

spinsmorefreelyandifthegearnoiseisreduced.

6. Continuemakingslightadjustmentsuntilyoundthe

positionwherethedrivewheelspinsmostfreelyand

thegearmakestheleastnoise.

7. Secure the shaft support plate in this position by

retighteningallthreenutsthatyouloosened.

FIGURE 16

Loading...

Loading...