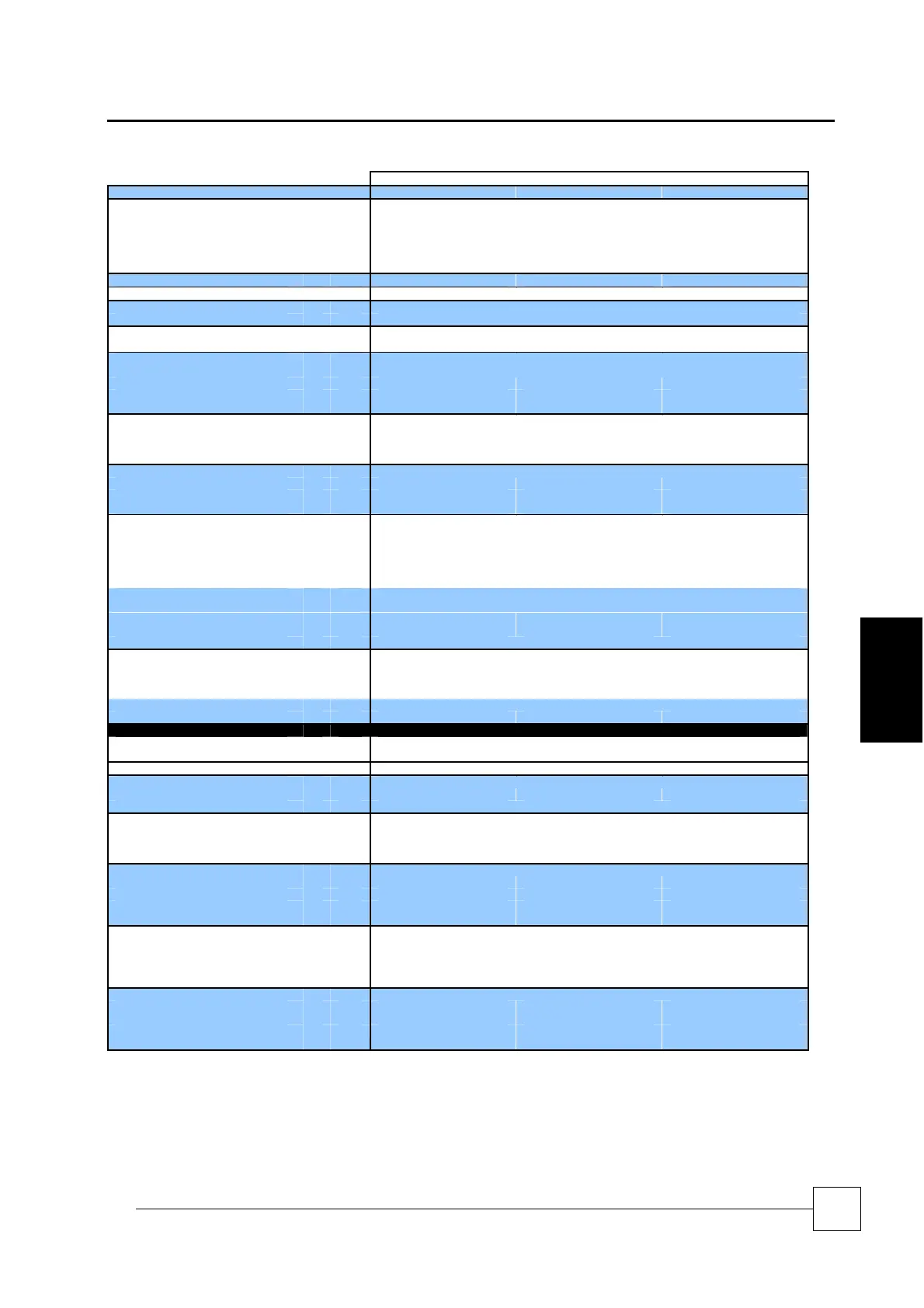

Mechanical Data – W2C0

SC19D033-W2C0 SC19D038-W2C0 SC19D045-W2C0

Standard Dry Cooler Match 1 x DR40 1 x DR55 1 x DR55

Capacity

Nom Cooling (Gross) – W2 (1) kW 29.1 36.8 42.3

Nom Cooling (Gross) – C0 (2) kW 61.6 67.9 74.4

Total Heat of Rejection – W2 kW 36.7 46.0 53.1

Capacity Steps 2 2 2

Fan Gain (6) kW 0.66 1.0 1.7

Dimensions – W x D x H

Mm 1985 x 890 x 1980 1985 x 890 x 1980 1985 x 890 x 1980

Weight – Machine / Operating

(3) Kg 850 / 880 860 / 890 860 / 890

Construction

Panels: Galvanised Sheet Steel, Epoxy Baked Powder Paint – Black Grey (RAL 7021)

Material/Colour Frame: Anodised Aluminium Frame with Black Nylon Corners

Evaporator

Rifled Copper Tube/Turbulated Hydrophilic Coated Aluminium Fins

Cooling/Dehum Stages 2/1 2/1 2/1

Cooling Coil – C0

Copper Tube/Turbulated Hydrophilic Coated Aluminium Fins

Cooling /Dehum Stages 1 (Modulated) / 1

Water Volume l 29.4 32.4 32.4

Water Flow l/s 2.44 2.72 3.14

Pressure Drop C0 kPa 30.9 27.8 35.0

Condenser

Stainless steel Brazed Plate

Water Volume l

Glycol Flow l/s 1.78 2.25 2.6

Pressure Drop Condenser kPa 86.13 50.48 66.22

Dry Cooler

Water Volume L 23.1 43.2 43.2

Flowrate l/s 1.78 2.25 2.6

Pressure Drop kPa 40.8 27 31.9

Fan Motor

Backwards Curved, Centrifugal direct drive

Motor Type EC EC EC

Quantity x Motor Size kW 2 x 2.2 2 x 2.2 2 x 2.2

Speed @25Pa / Maximum ESP RPM 964 / 1360 1117 / 1360 1340 / 1360

Maximum ESP Pa 438 302 49

Nominal Airflow m³/s 3.7 4.3 5.1

Compressor – Scroll

Configuration – W2C0 Dual Cool – Circuit 1 Tandem Compressors (Water Cooled) / Circuit 2 Chilled Water

Quantity – W2C0 2 2 2

Oil Charge Volume – W2C0 l 2 x 1.57 2 x 1.57 2 x 1.57

Oil Type Polyolester

Connections

Water Inlet / Outlet –W2 mm 35 35 35

Water Inlet / Outlet – C0 mm 35 35 35

Condensate Drain Hose mm 22 22 22

Filtration Disposable to BS EN 779-G4

Quantity 3 3 3

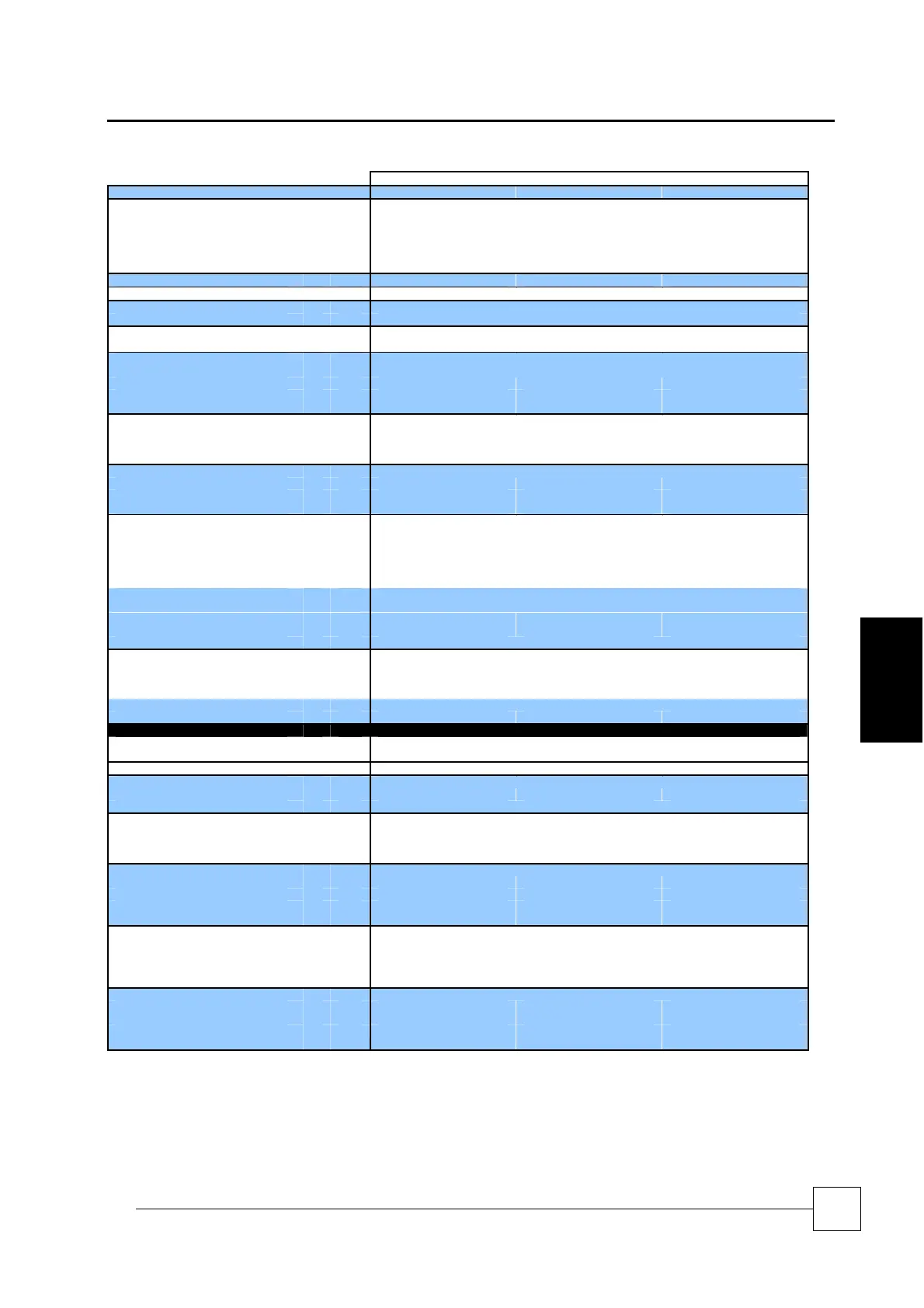

OPTIONAL EXTRAS

Hot Gas Reheat -

Nom Heating (Gross) kW 8.1 8.9 9.5

Electric Heating (Total)

kW 21 21 21

Humidifier

Capacity kg/hr 8 8 8

Feed/Drain 3/4" BSPF Braided flexible hose / 19mm hose connection

Condensate Pump

Head m 10.8 10.8 10.8

Flow l/m 5 5 5

Drain 10mm Stainless steel Stub Connection

First upgrade Motor - EC Motor

Backwards Curved, Centrifugal direct drive

Quantity x Motor Size kW 2 x 3.1 2 x 3.1 2 x 3.1

Speed @ 25Pa / Maximum ESP rpm 986 / 1510 1145 / 1520 1364 / 1510

Maximum ESP Pa 589 453 216

Fan Gain (6) kW 0.65 1.03 1.73

Second upgrade Motor - EC Motor

Quantity x Motor Size kW N/A N/A N/A

Speed @ 25Pa / Maximum ESP rpm N/A N/A N/A

Maximum ESP Pa N/A N/A N/A

Fan Gain (6) kW N/A N/A N/A

Low Pressure Hot Water

(5) Copper Tube/Aluminium Fin

Capacity Gross kW 22.16 24.45 26

Water Flow (Nominal) l/s 0.49 0.54 0.58

Pressure drop kPa 9.4 9.7 10.1

LPHW Connection Sizes mm 22 22 22

(1) Entering air 24°C/45% RH condensing water in / out: 35/40°C

(2) Entering air 24°C/45% RH water 7°C/12°C

(3) Machine weight Includes a refrigerant charge / Operating weight includes calculated water volume

(4) Based on air temperature of 15.5 °C leaving the evaporator coil

(5) Based upon low pressure hot water 82 °C inlet / 71°C outlet. Air on 20°C.

(6) Fan gain based on 25 Pa ESP @ nominal air volume. Fan gain figure will change as airflow and ESP change.

W2C0

Loading...

Loading...