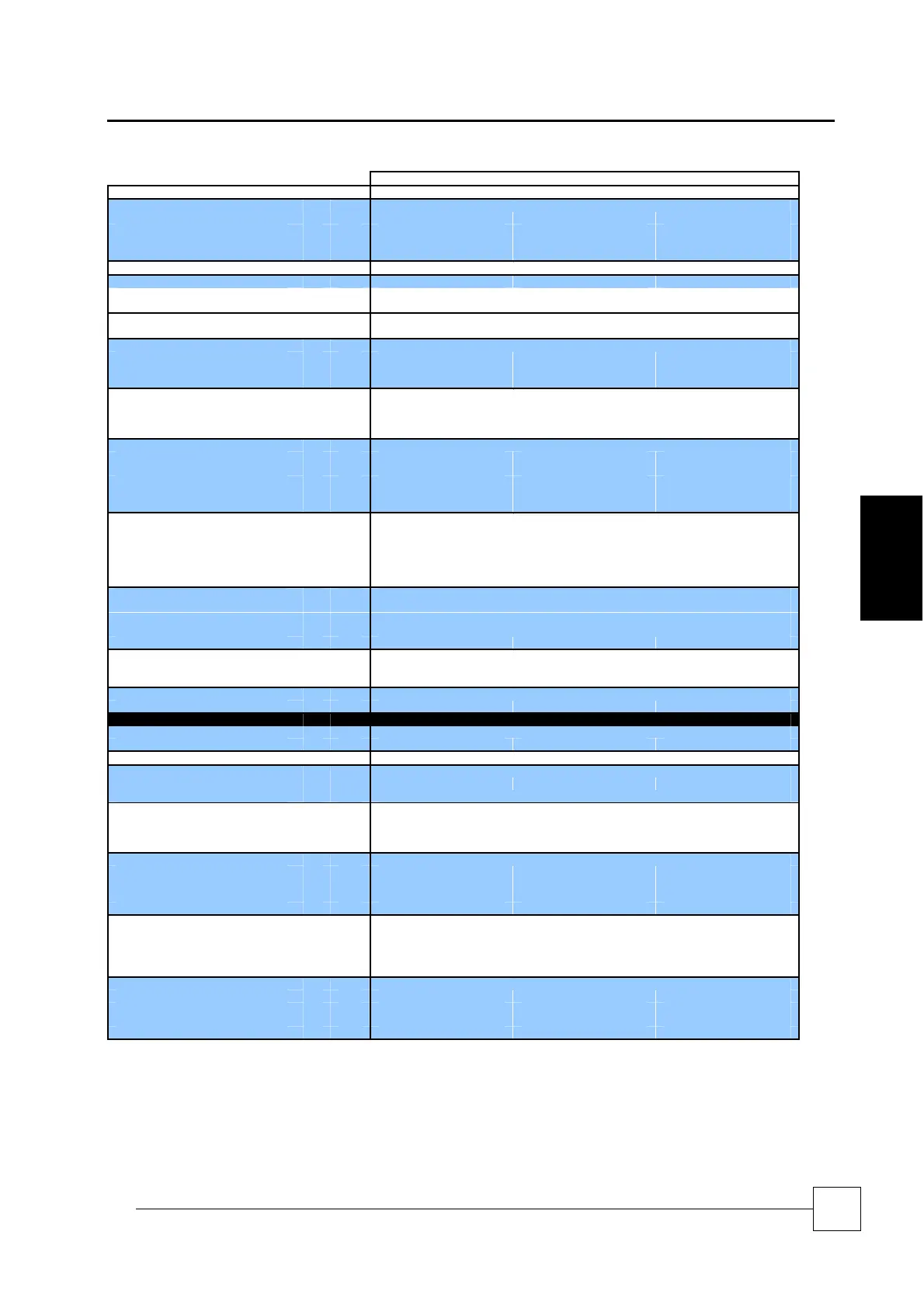

Mechanical Data – W2W2

SC19D055-W2W2 SC19D070-W2W2 SC19D080-W2W2

Standard Dry Cooler Match 2 x DR40 2 x DR55 2 x DR55

Capacity

Nom Cooling (Gross) – W2 (1) kW 53.0 66.9 76.1

Total Heat of Rejection – W2 kW 68.2 85.6 97.7

Capacity Steps 4 4 4

Fan Gain (5) kW 0.55 1.12 1.7

Dimensions – W x D x H

mm 1985 x 890 x 1980 1985 x 890 x 1980 1985 x 890 x 1980

Weight – Machine / Operating

(2) Kg 940 / 940 970 / 980 970 / 980

Construction

Panels: Galvanised Sheet Steel, Epoxy Baked Powder Paint – Black Grey (RAL 7021)

Material/Colour Frame: Anodised Aluminium Frame with Black Nylon Corners

Evaporator

Rifled Copper Tube/Turbulated Hydrophilic Coated Aluminium Fins

Cooling/Dehum Stages 4/1 4/1 4/1

Condenser

Stainless Steel Brazed Plate

Water Volume L 4.1 10 10

water Flow l/s 1.65 2.08 2.39

Pressure Drop Condenser kPa 71.9 35.3 35.3

Dry Cooler

Water Volume L 23.1 43.2 43.2

Flowrate l/s 1.65 2.08 2.39

Pressure drop kPa 35 25 30

Fan Motor

Backwards Curved, Centrifugal direct drive

Motor Type EC EC EC

Quantity x Motor Size kW 2 x 2.2 2 x 2.2 2 x 2.2

Speed @25Pa / Maximum ESP RPM 906 / 1360 1160 / 1360 1280 / 1360

Maximum ESP Pa 490 260 110

Nominal Airflow m³/s 3.5 4.4 5.1

Compressor – Scroll

Configuration – W2W2

Dual Circuit– Circuit 1 Tandem Compressors (Water Cooled)

Circuit 2 Tandem Compressors (Water Cooled)

Quantity – W2W2 2 2 2

Oil Charge Volume – W2W2 l 4 x 1.57 4 x 1.57 4 x 1.57

Oil Type Polyolvinyl

Refrigeration

Dual Circuit

Refrigerant control and type Thermostatic Expansion Valve (Optional EEV)

Refrigerant type R410A

Holding Charge Inert Gas

Charge (Per circuit) kg 5.75 7.32 7.32

Connections

Water Inlet / Outlet –W2 mm 35 35 35

Condensate Drain Hose mm 22 22 22

Filtration Disposable to BS EN 779-G4

Quantity 3 3 3

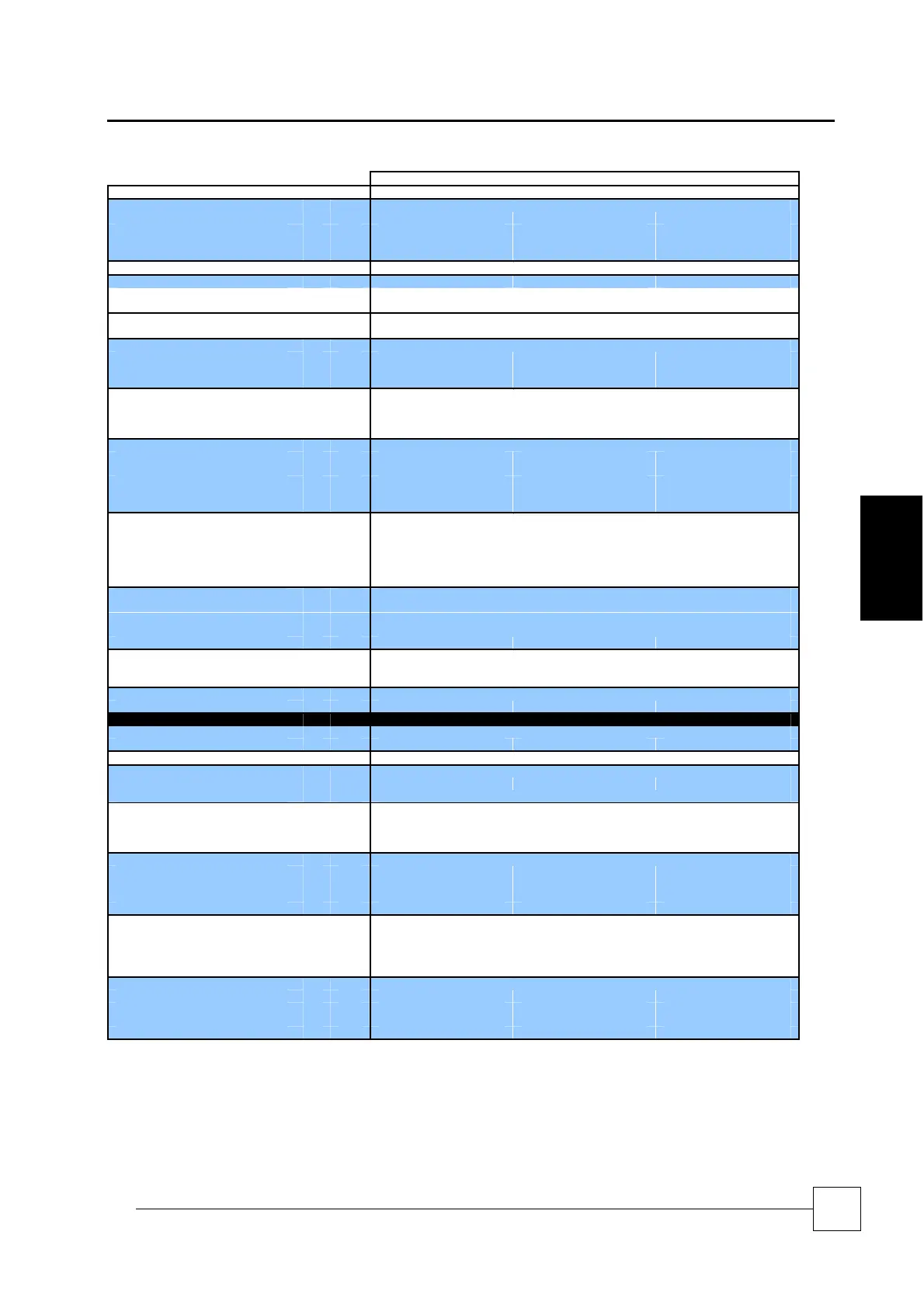

OPTIONAL EXTRAS

Hot Gas Reheat -

(3)

Nom Heating (Gross) kW 8.1 8.9 9.5

Electric Heating (Total)

kW 21 21 21

Humidifier

Capacity kg/hr 15 15 15

Feed/Drain 3/4" BSPF Braided flexible hose / 19mm hose connection

Condensate Pump

Head m 10.8 10.8 10.8

Flow l/m 5 5 5

Drain 10mm Stainless steel Stub Connection

First upgrade Motor - EC Motor

Backwards Curved, Centrifugal direct drive

Quantity x Motor Size kW 2 x 3.1 2 x 3.1 2 x 3.1

Speed @ 25Pa / Maximum ESP rpm 922 / 1500 1187 / 1520 1364 / 1520

Maximum ESP Pa 640 411 215

Fan Gain (5) kW 0.55 1.14 1.73

Second upgrade Motor - EC Motor

Quantity x Motor Size kW N/A N/A N/A

Speed @ 25Pa / Maximum ESP rpm N/A N/A N/A

Maximum ESP Pa N/A N/A N/A

Fan Gain (5) kW N/A N/A N/A

Low Pressure Hot Water

(4) Copper Tube/Aluminium Fin

Capacity Gross kW 22.16 24.45 26

Water Flow (Nominal) l/s 0.49 0.54 0.58

Pressure drop kPa 9.4 9.7 10.1

LPHW Connection Sizes mm 22 22 22

(1) Entering air 24°C/45% RH condensing water in / out: 35/40°C

(2) Machine weight Includes a refrigerant charge / Operating weight includes calculated water volume

(3) Based on air temperature of 15.5 °C leaving the evaporator coil

(4) Based upon low pressure hot water 82 °C inlet / 71°C outlet. Air on 20°C.

(5) Fan gain based on 25 Pa ESP @ nominal air volume. Fan gain figure will change as airflow and ESP change.

W2W2

Loading...

Loading...