Preventative Maintenance

Table 6-1 provides PM guidelines that should be followed for optimal performance. Following these guidelines

will help avoid serious damage to components and expensive repairs by skilled personnel.

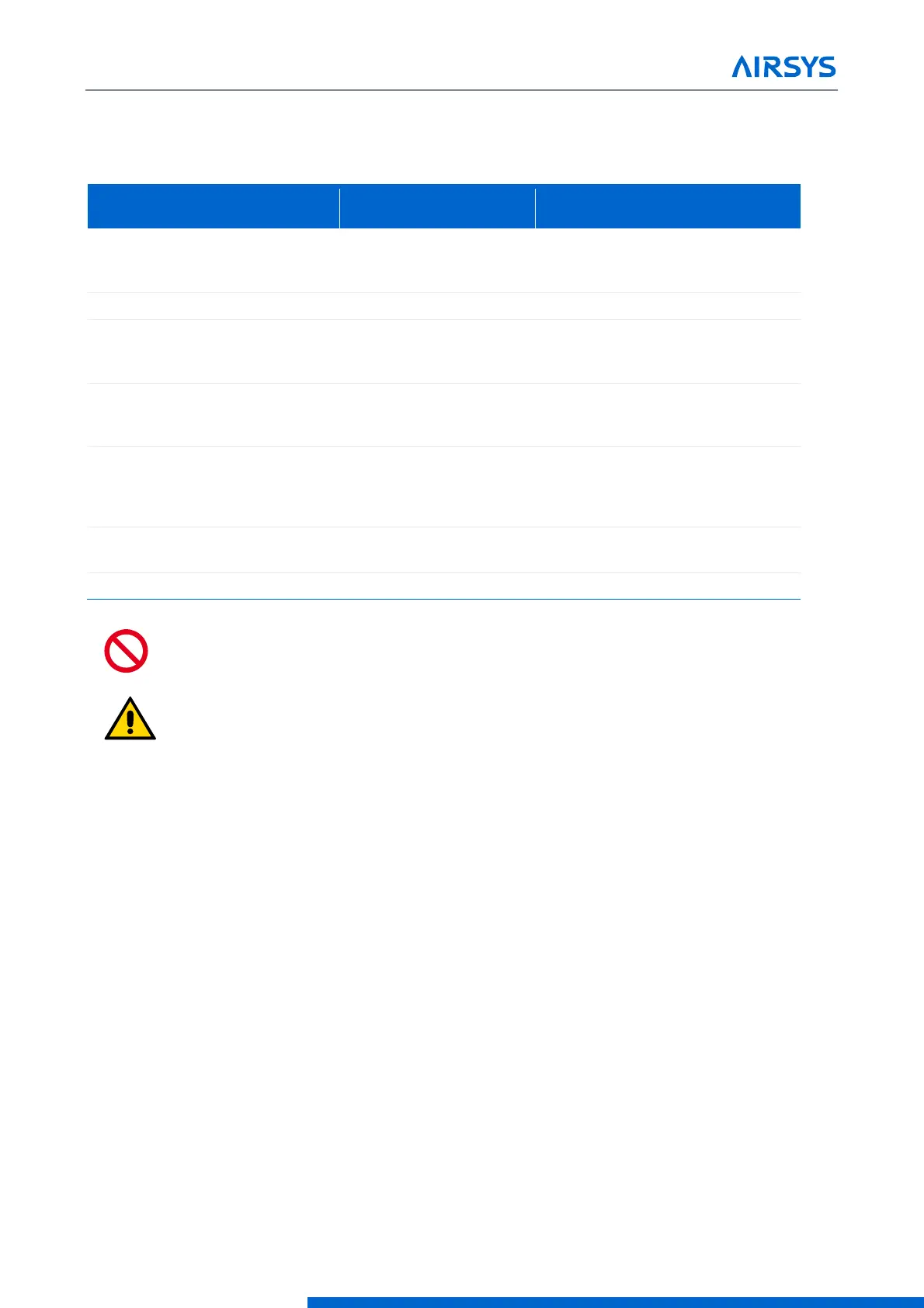

Table 6-1 Preventative Maintenance Schedule

Inspect all wiring for signs of wear

Based on local conditions

More frequently in areas with active

rodent or insect populations that

can damage wiring

Inspect all hardware for “snug”

connection

Make note of any loose hardware

so it can be checked again at next

scheduled PM

Air filter inspection/cleaning and

replacement if needed

Based on local conditions

Depends on the amount and

frequency of airborne particulates in

the area

Inspect and clean condenser coil

Based on local conditions

More frequently in areas that

experience excessive airborne

particulates that will collect on the

condenser coil

Inspect drain pipes (condenser

and evaporator)

Physical Inspection of Air Damper

Danger. Stop the machine and remove the power supply from the equipment

before performing maintenance operations.

Important. All PM should be performed by an AIRSYS Authorized Service

Technician (AAST) to ensure that the manufacturer’s warranty is preserved.

6.1 General Operation Check

It is a good idea to compare the operation of the equipment with the results of the previous inspection. Any

differences in operating characteristics can then be easily identified.

A detailed and periodic visual inspection of the equipment and a general cleaning are both important to ensure

good operation. Before beginning the PM steps, the general system status should be verified by looking at the

areas outlined in this section.

6.1.1 Check Main Voltage

Check that:

• The main voltage is within ±15% of the rated voltage required by the machine.

• The DC voltage is in normal range, if applicable. (36 -57VDC)

• The main electrical supply cable and the terminals, including the user terminal cable, are correctly

connected.

• All cables are secured to the system.

Loading...

Loading...