Preventative Maintenance

6.1.2 Check Wiring and Components

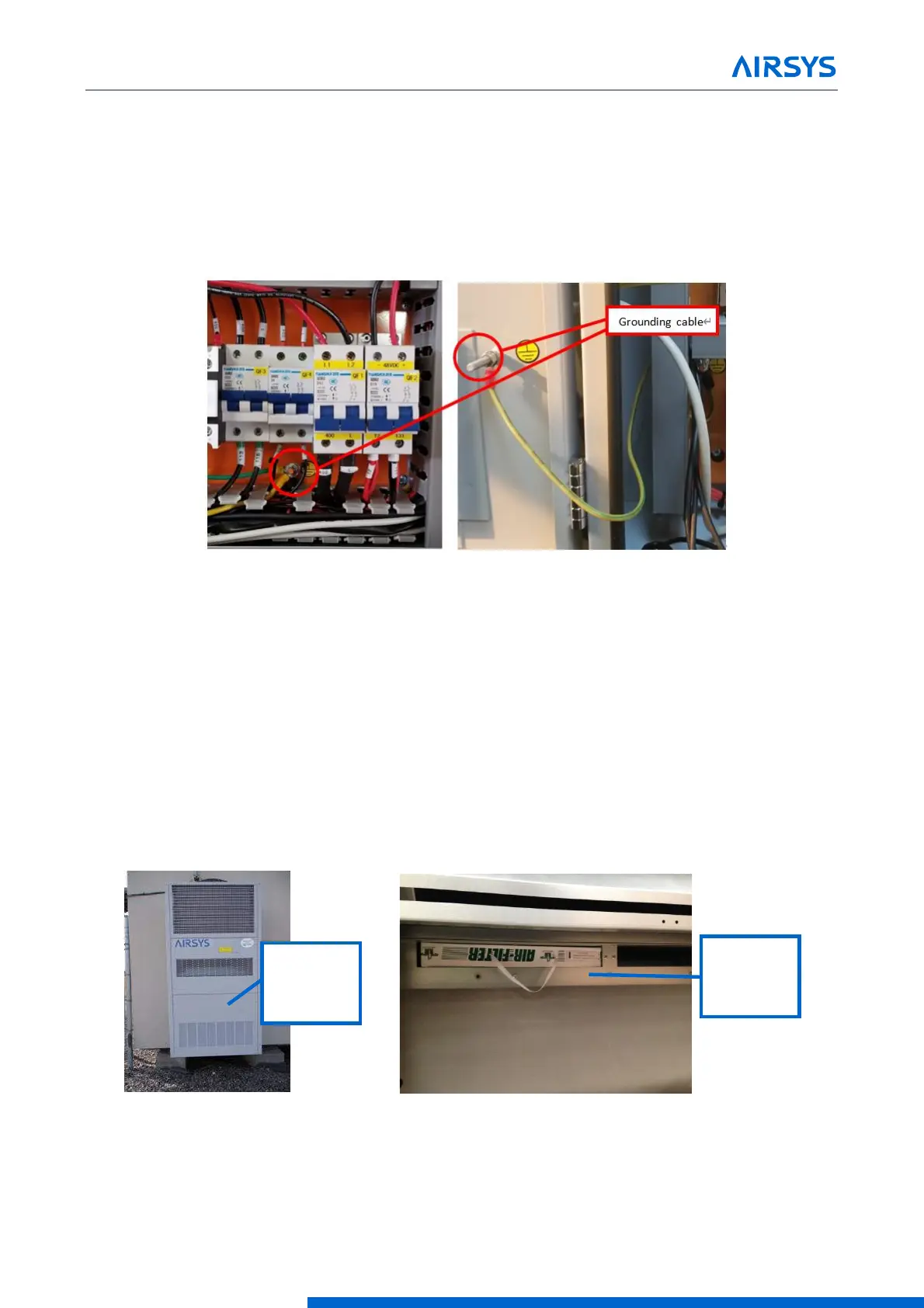

For wiring and components, perform a preliminary check to verify the system is functional:

• Check that the system has been installed correctly.

• Check that the wiring cable sections meet current capacity. Report any incorrect mounting and setting to

the AAST who installed the system so that the necessary modifications can be made.

• Check that the grounding cables have been installed in the controller box and unit as shown in the graphic.

6.1.3 Perform the Step-Test

The purpose of this test is to simulate real operation without damaging components due to incorrect operation

or protection failures.

Use the step test to check that the relays, breakers, and components work normally. For details, see “Execute

the Step-Test” on Page60.

6.1.4 Replace Air Filter

A dirty air filter reduces the air volume and the system capacity. This problem can be avoided by regularly

cleaning or replacing filters. The frequency at which filters must be checked depends on the amount of dust in

the environment. If the filters are frequently very dirty, the frequency of checks and maintenance should be

increased.

6.1.5 Clean the Preliminary Air Filter

The preliminary air filter can become clogged with dust and leaves or other debris after a period of use and

should be cleaned with water or compressed air.

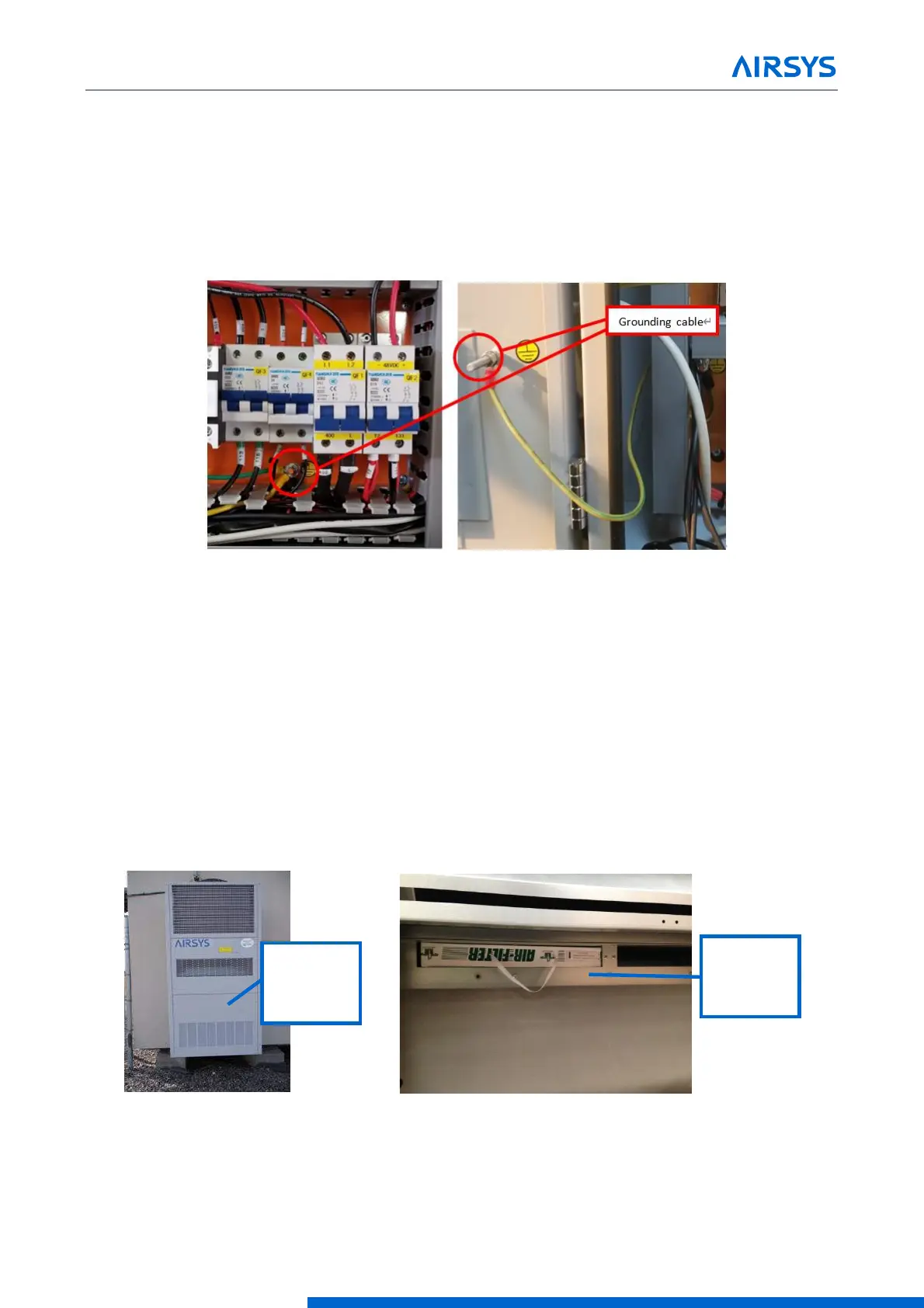

Remove

middle-front

panel

Replace the

filter(s)

Loading...

Loading...