Page 10

All setup functions except the Stow and Deploy Positions can be scrolled through by pressing the Stream switch. Each

time the Stream switch is pressed, another function is active for conguration. If a function is congured and saved

using the Fog switch, the next function will be automatically selected. Activating the Stream command will abort this

function without storing the position and the next function will be selected. Entering the Stow and Deploy Positions

programming modes can only be accomplished by activating the Stow or Deploy switch while at the start of the setup

menu (LED Code 1 Slow blink). (See the sections for Stow Position and Deploy Position for more detail).

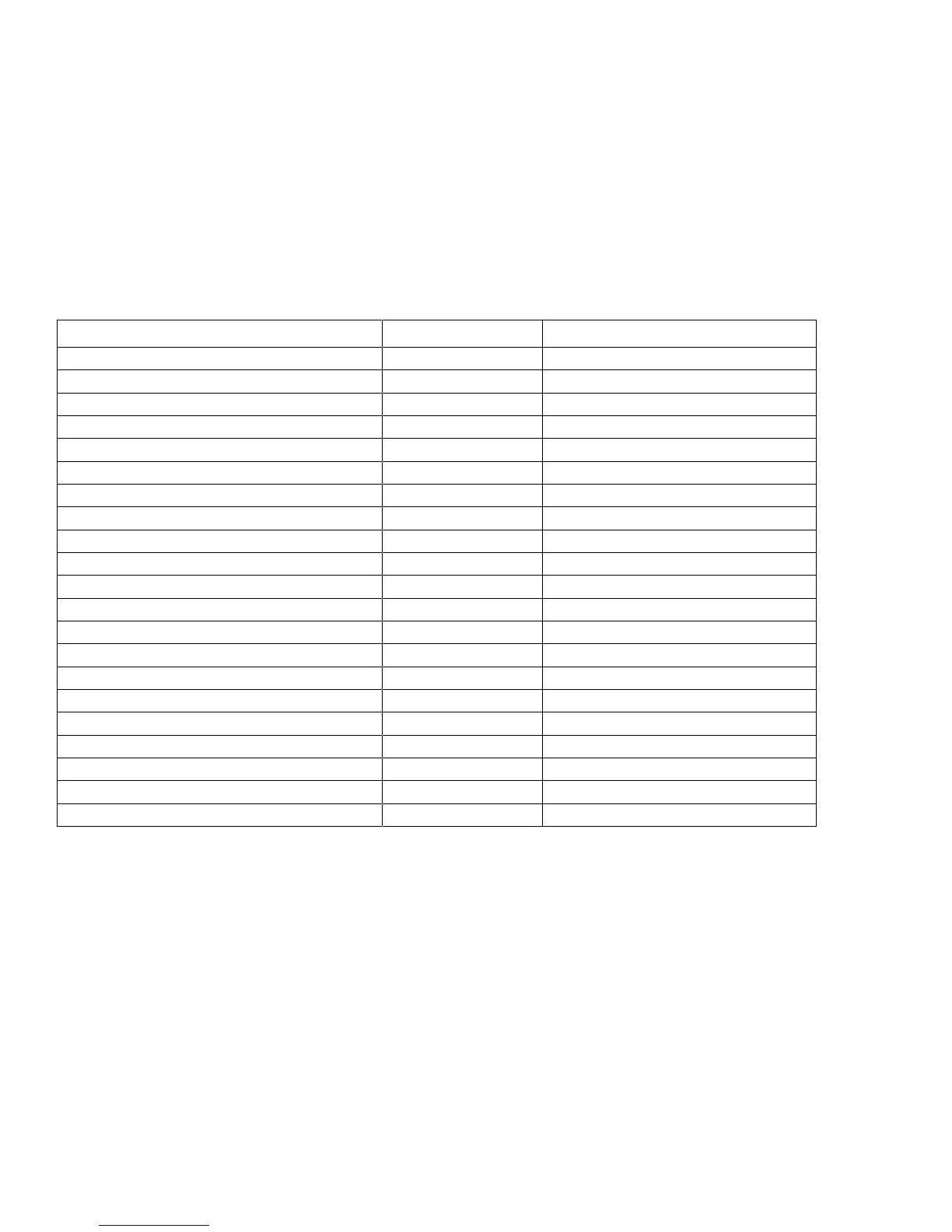

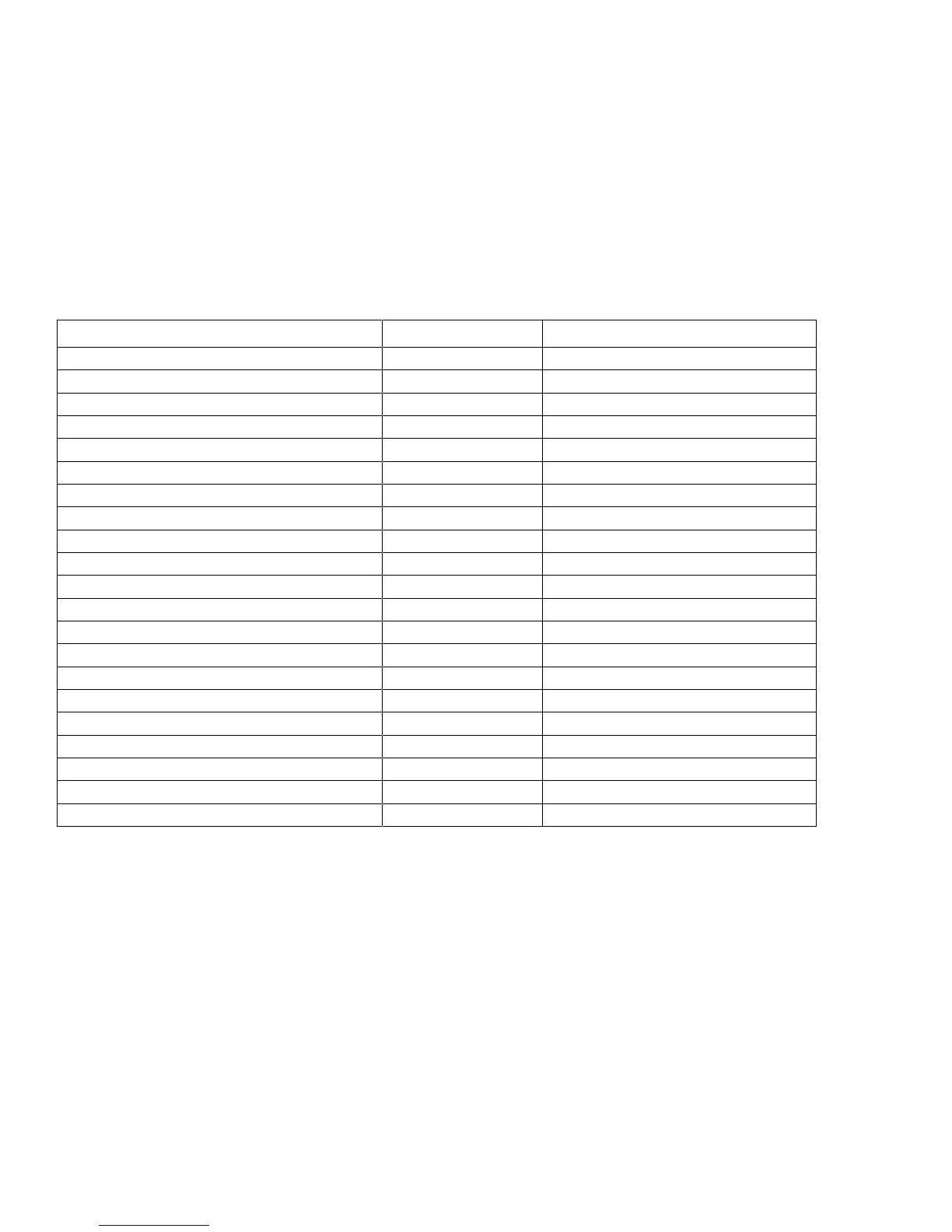

To aid in determining which setup menu the monitor is in, the LED on the operator station has been programmed to blink

a different code for each function. Table 3-1 below lists the LED codes for each function. The codes have two parts.

The LED code will start with either one, two, three or four short blinks, a short pause (LED off), another series of short

blinks, then a long pause (LED off). The rst number in the LED code is the one, two, three or four blinks and the second

number is the second series of blinks before the long pause. If an OEM is using their own operator station that has no

LED, the codes will also be available on pin #7 of the 29 pin interface connector on the UII logic box.

Setup Parameter Blink Code 34405XXX Position Feedback Units

Beginning of setup 0-1 (One slow blink) Programming Order (See Notes)

Right Soft Limit 1-1 NOTE 2

Left Soft Limit 1-2 NOTE 2

Up Soft Limit 1-3 NOTE 2

Down Soft Limit 1-4 NOTE 2

Stow 1-5 NOTE 4

Deploy 1-6 NOTE 4

Monitor Orientation 1-7

Zero Position Sensors 1-8 NOTE 1

Restore Factory defaults 1-9

Obstacle avoidance Disable 2-1

Obstacle Avoidance Manual Operation 2-2 NOTE 3

Obstacle Avoidance Auto Operation 2-3 NOTE 3

Obstacle Avoidance Learn 2-4 NOTE 3

Stow rotation position 2-7 NOTE 4

Electric Riser disable 3-1

Electric Riser enable 3-2

CAN Valve Disable 4-1

CAN Valve Enable 4-2

CAN Valve Pair 4-3

CAN Valve Calibrate 4-4

NOTES:

1. This step only needs to be done in two cases. If there is a position indicator in the system and/or the monitor is

mounted such that the physical rotational zero position is not in line with the physical center of the apparatus.

If needed, this step must be done rst before setting ANY other positions. This setting will erase any previously set

positions including obstacle avoidance and stow/deploy.

2. These steps must be performed. The soft limits must be programmed so that the monitor stops before hitting a

hard limit. Hitting a hard limit will cause a sensor error code. If there is an active sensor error code, all soft limits and

automatic functions (stow/deploy, oscillation and obstacle avoidance) are ignored and the monitor will move

throughout its entire physical range with no restrictions which could cause collisions with the truck or truck

mounted obstacles.

3. These steps are optional and depend on the application needs.

4. Stow/Deploy position programming should be done after soft limits and obstacle avoidance (if used)

Loading...

Loading...