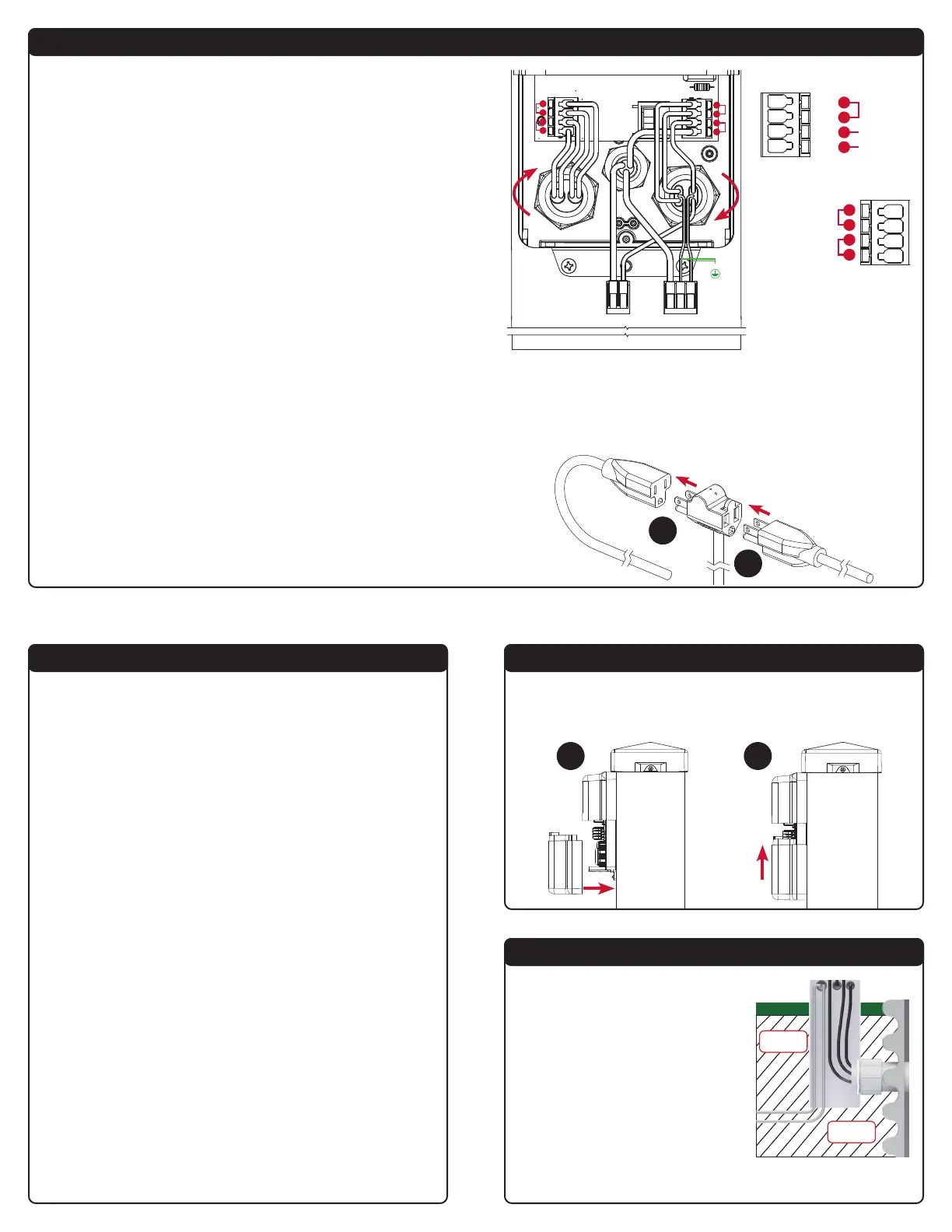

Step 5: Wiring and Piggyback Plug Connections

Step 6: Testing

The wiring diagram shows eight terminals on the quick snap terminal

blocks that consists of four pairs of connections. Make sure to read and

review the connector examples in step 4 for proper installation prior to

wiring.

Note: The quick snap terminal blocks, are herein referred to as “terminal”

for instruction purposes. The installation example shown is for 120VAC,

for 240VAC installation the neutral (N) wire would be replaced by line

connection (L2) and white wire would include a red band to indicate the

wire is hot.

1) The rst cable grip, starting at the right, has a cable grip divider

allowing for two power sources to be brought into the enclosure. The

right side of the cable grip is used for the pump power (attached in

series). The line wire is connected to terminal 7 and neutral wire is

terminated by the two-position Wago connector. The left side of the

cable grip is used for the alarm power, which is connected to

terminals 5 and 6. Terminal 5 is the neutral (N) connection and

terminal 6 is the line connection (L1). The pump and alarm power

ground wires are terminated using the three-position Wago

connector. After bringing in the cables, rmly tighten the cable grip

by twisting clockwise until securely fastened.

2) The female receptacle comes pre-installed in the middle cable grip.

The line wire is connected to terminal 8, neutral wire is terminated by

the two-position Wago connector, and ground wire is terminated by

the three-position Wago connector.

3) The third cable grip has a cable grip divider allowing for two sensor

connections. The lter switch is connected to terminals 1 and 2. The

high level alarm oat switch is connected to terminals 3 and 4. After

bringing in the cables, rmly tighten the cable grip by twisting

clockwise until securely fastened.

4) NEVER leave ground wire(s) exposed, use provided Wago

connector for wire termination.

(120VAC Example Shown)

5B

5A

PIGGYBACK PLUG CONNECTIONS

1) Plug the male end of the piggyback plug on the pump switch power

cable into the pre-installed female power receptacle inside the post (5A).

2) Plug the male end of the pump power cable into the female end of

the piggyback plug on the pump switch power cable (5B) from #1.

Alarm Wiring

(step 3)

Filter Switch

Alarm Float Switch

1

2

3

4

Make sure all steps of the installation and wiring process is completed

and there is power to the product.

1) TEST ALARM LEDs and BUZZER

Press the test/silence pushbutton, lifetime pump run event counter

statistic should display, then alarm LEDs should illuminate while

cycling between red, green, blue, and off. The OLED screen should

display a TESTING (COLOR) event for respective LEDs after the event

statistic is displayed. Last, the buzzer should annunciate and OLED

screen should display a TESTING BUZZER event.

2) TEST ALARM FLOAT SWITCH

Activate the alarm oat switch, the red LEDs should illuminate,

ashing and the buzzer should annunciate. The OLED screen should

display a HIGH LEVEL ALARM event.

3) TEST ALARM SILENCE

Press the test/silence pushbutton on the front of the enclosure while

the alarm oat switch is activated. The red LEDs should keep ashing

and the buzzer should silence.

4) TEST FILTER SWITCH

Activate the lter switch, the amber LEDs should illuminate, ashing

and the buzzer should annunciate. The OLED screen should display a

FILTER ALARM event.

5) TEST PUMP AND PUMP FLOAT SWITCH

Make sure the tank has water to perform the testing. Activate the pump

oat switch, the blue LEDs should illuminate and the OLED screen

should display a PUMP RUN event and the pump amps are displayed.

6) RECOMMENDED SYSTEM SETTINGS

Alderon™ recommends changing the factory settings for: high amp

level, extended pump run time, and gallons per minute.

7) TEST WEEKLY

To ensure the product is functioning properly, test once a week.

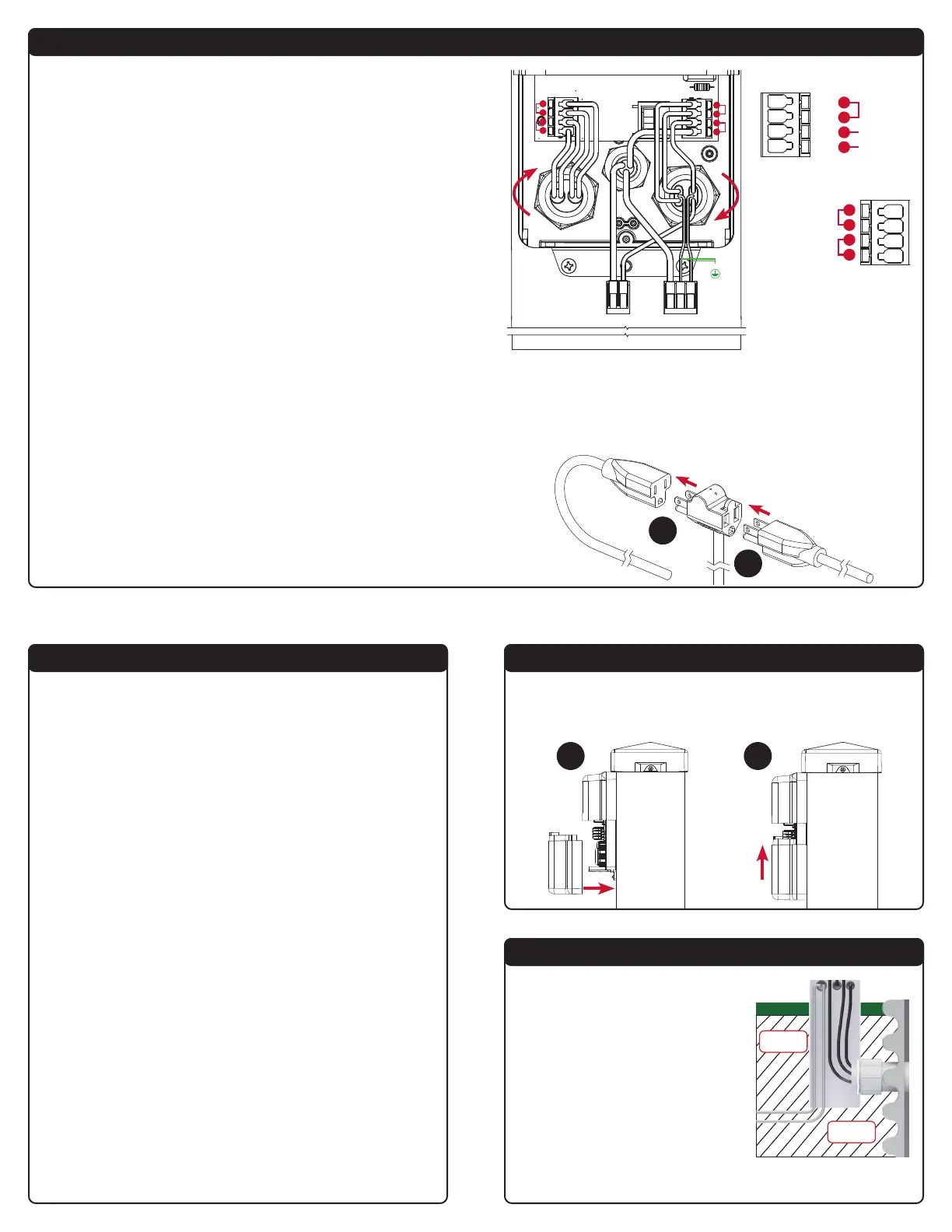

Step 7: Install Bottom Cover

Line up the bottom enclosure cover with the grooves (7A), then slide

directly upward (7B) until it meets the top of the enclosure so the screw

hole is lined up and replace the screw at the bottom of enclosure.

Step 8: Backll

Make sure all steps of the installation,

wiring, and testing are complete. Take

the dirt/soil removed and backll the

area for the post, riser, and direct

burial power wiring.

Backll

Area

Backll

Area

7A 7B

BLACK

BLACK

BLACK

BLACK

WAGO WAGO

GROUND

WHITE/RED

WHITE

WHITE/RED

WHITE

BLACK

WHITE

GROUND

5

6

7

8

1

2

3

4

Power Wiring

(steps 1 and 2)

Alarm Power

Pump Power

5

6

7

8

Factory Wired

N/L2

L1

L1

Loading...

Loading...