SER 7342 High-Capacity Reel

Revision (10-13) 12 Alemite LLC

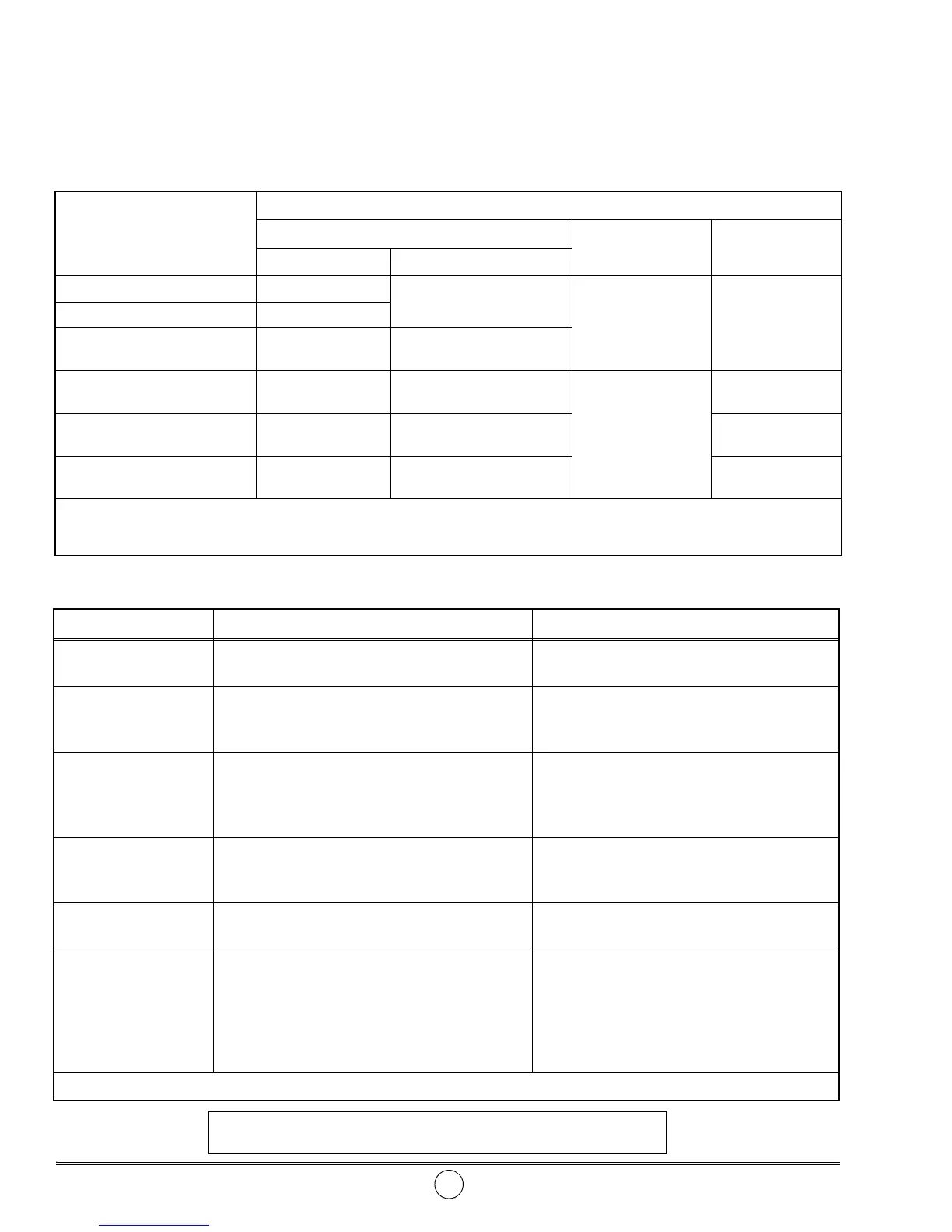

Reel Packages

Hose reel model 7342 is included in the reel packages listed below.

IMPORTANT: The Power Spring tension is preset at the factory for most installations. Once the reel pack-

age is installed and the system is pressurized, refer to the section entitled Checking Spring Tension.

Reel Package Model

Outlet Components

Delivery Hose *

Reducing Bushing Hose Stop

Part Number Description

8080-E 317868-50

3/4 “ID Single-Wire Braid

3/4" NPTF (m) x 3/4" NPTF (m)

320353 339389

8080-F 317868-70

8080-FA 343069-70

3/4" ID Single-Wire Braid

3/4" NPTF (m) x 3/" BSPP (f)**

8080-G 317869-50

1 " ID Single-Wire Braid

1" NPTF (m) x 1" NPTF (m)

Not Used

339389-1

8080-GA 343065-50

3/4 " ID Single-Wire Braid

1" NPTF (m) x 1" BSPP (f)**

339389-1

8080-J 339634-50

1 " ID Fuel

1" NPTF (m) x 1" NPTF (m)

339389-1

* The length of the delivery hose is designated by the suffix in the part number. Example: 317868-50 is 50 feet long.

Hoses are electrically conductive and are suitable for dispensing diesel fuel and gasoline.

** Swivel with 60 seat

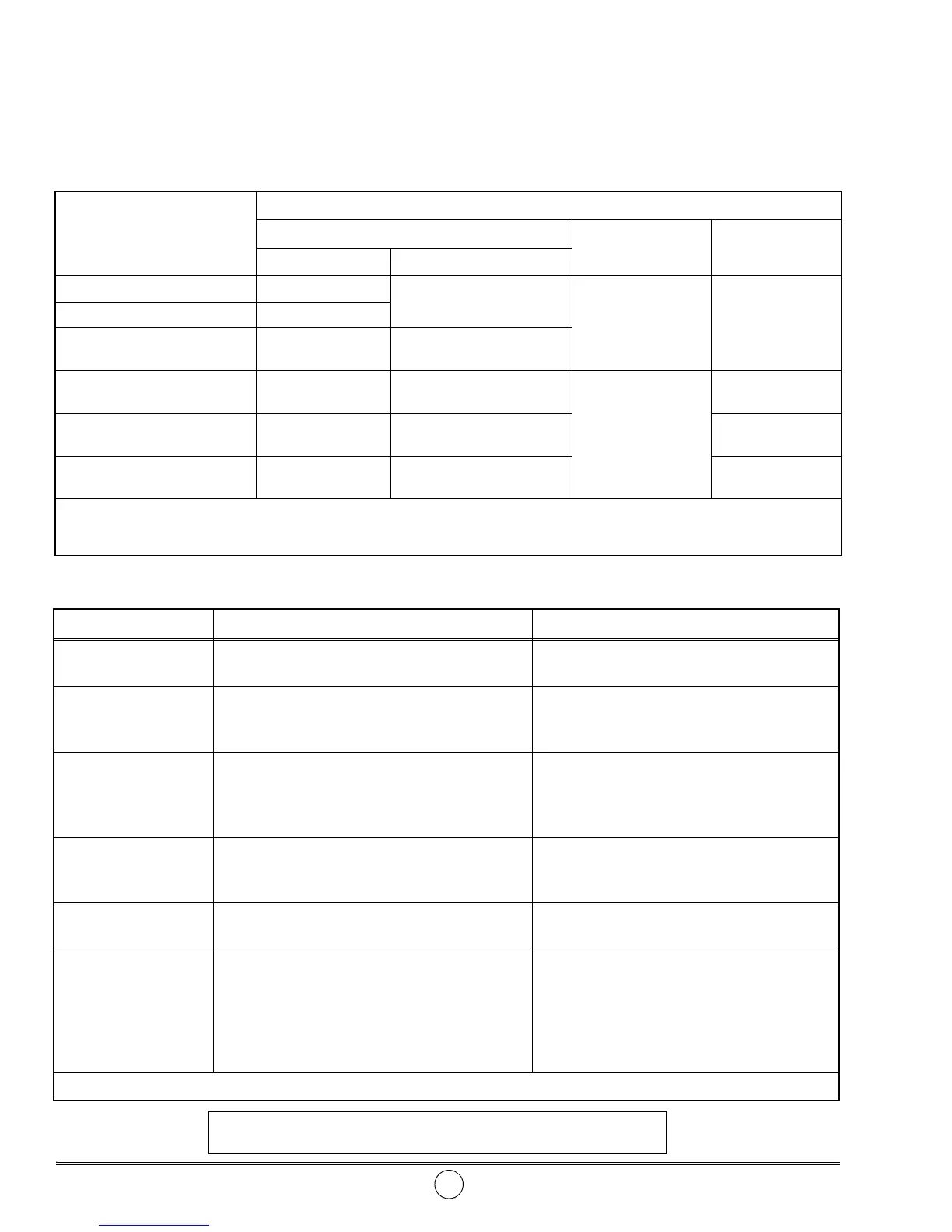

Troubleshooting Chart

Indications Possible Problems Solution

Reel does not latch Extension Spring (23) broken or not attached to

Pawl and Shaft Assembly (24)

Replace or secure Extension Spring (23)

Reel does not retract 1. Power spring broken*

2. Worn or damaged Swivel Body (38) and/or

Shaft and Riser Assembly (6)

1. Replace Power Spring Assembly (11)

2. Replace Swivel Body (38) and/or Shaft and

Riser Assembly (6)

Reel retracts partially 1. Improper power spring tension

2. Worn or damaged Swivel Body (38) and/or

Shaft and Riser Assembly (6)

3. Hose length greater than recommendation

1. Set tension properly

2. Replace Swivel Body (38) and/or Shaft and

Riser Assembly (6)

3. Refer to Table 1

Reel does not unlatch

after maximum length

of hose is removed

1. Power spring wound solid

2. Hose removed from the reel too quickly

(Over-Rotation of Reel)

1. Decrease power spring tension

2. Pull the hose slowly when close to being

fully extended

Material leakage at the

Swivel Assembly

Worn or damaged O-Ring (39) and T-Seal (40) Use Repair Kit 393725

Material leakage from

Sheave Assembly (2)

and/or delivery hose

1. Delivery hose connection [or Bushing (7)]

not sufficiently tight into Shaft and Riser

Assembly (6)

2. Delivery hose connection not sufficiently

tight into Bushing (7) and/or thread sealant

missing or inadequate

1. Tighten connection

2. Apply thread sealant to delivery hose and

tighten into Bushing (7)

* The possible causes for broken components are listed in italics

Changes Since Last Printing

Added trademark attribution. Changed 8080-J Hose Stop to 339389-1 (was 339389-2).

Loading...

Loading...