Paragraphs 230-234

ALLIS-CHALMERS

to remove transmission and mainshaft

as in paragraph

227.

Remove lock plate

(21) from rear of case and bump idler

gear shaft out toward the rear and

withdraw gear through the top of the

case.

Bushing in reverse gear is re-

newable and must be reamed after in-

stallation, to provide .001-.002 inch

clearance.

Model

WD

Prior 127008

First type transmissions have

a

straight

(not curved) gear shiiting lever and straight

cut gear teeth.

230.

BASIC PROCEDURE. Trans-

mission shafts, differential unit and

final drive bevel pinion and ring gear

are carried in the one housing. Over-

haul of any of the transmission shafts,

except the main drive shaft (transmis-

sion clutch shaft), requires removal of

transmission as outlined in paragraph

231.

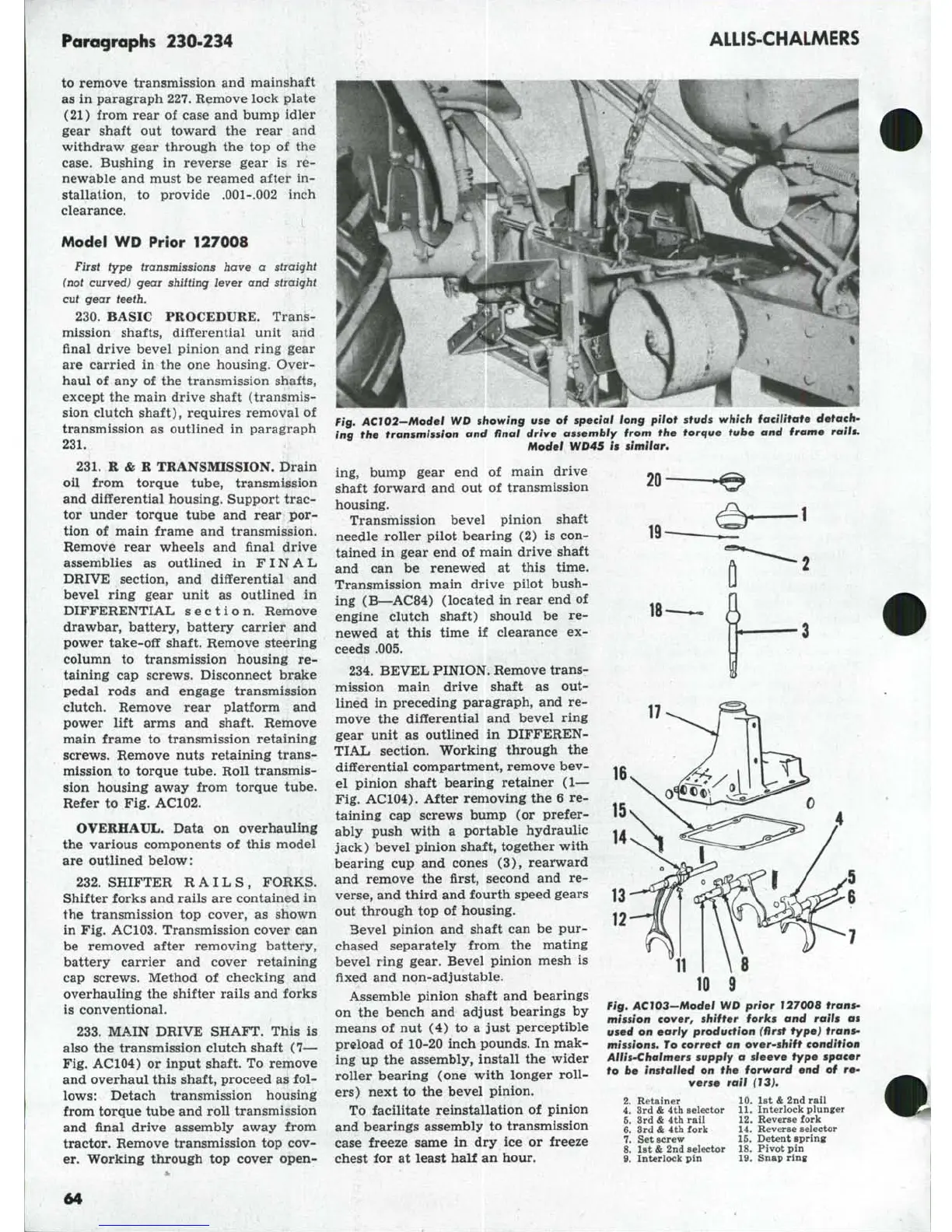

231.

R&R

TRANSMISSION. Drain

oil from torque tube, transmission

and differential housing. Support trac-

tor under torque tube and rear por-

tion of main frame and transmission.

Remove rear wheels and final drive

assemblies as outlined in FINAL

DRIVE section, and differential and

bevel ring gear unit as outlined in

DIFFERENTIAL section. Remove

drawbar, battery, battery carrier and

power take-off shaft. Remove steering

column to transmission housing re-

taining cap screws. Disconnect brake

pedal rods and engage transmission

clutch. Remove rear platform and

power lift arms and shaft. Remove

main frame to transmission retaining

screws.

Remove nuts retaining trans-

mission to torque tube. Roll transmis-

sion housing away from torque tube.

Refer to Fig. AC102.

OVERHAUL. Data on overhauling

the various components of this model

are outlined below:

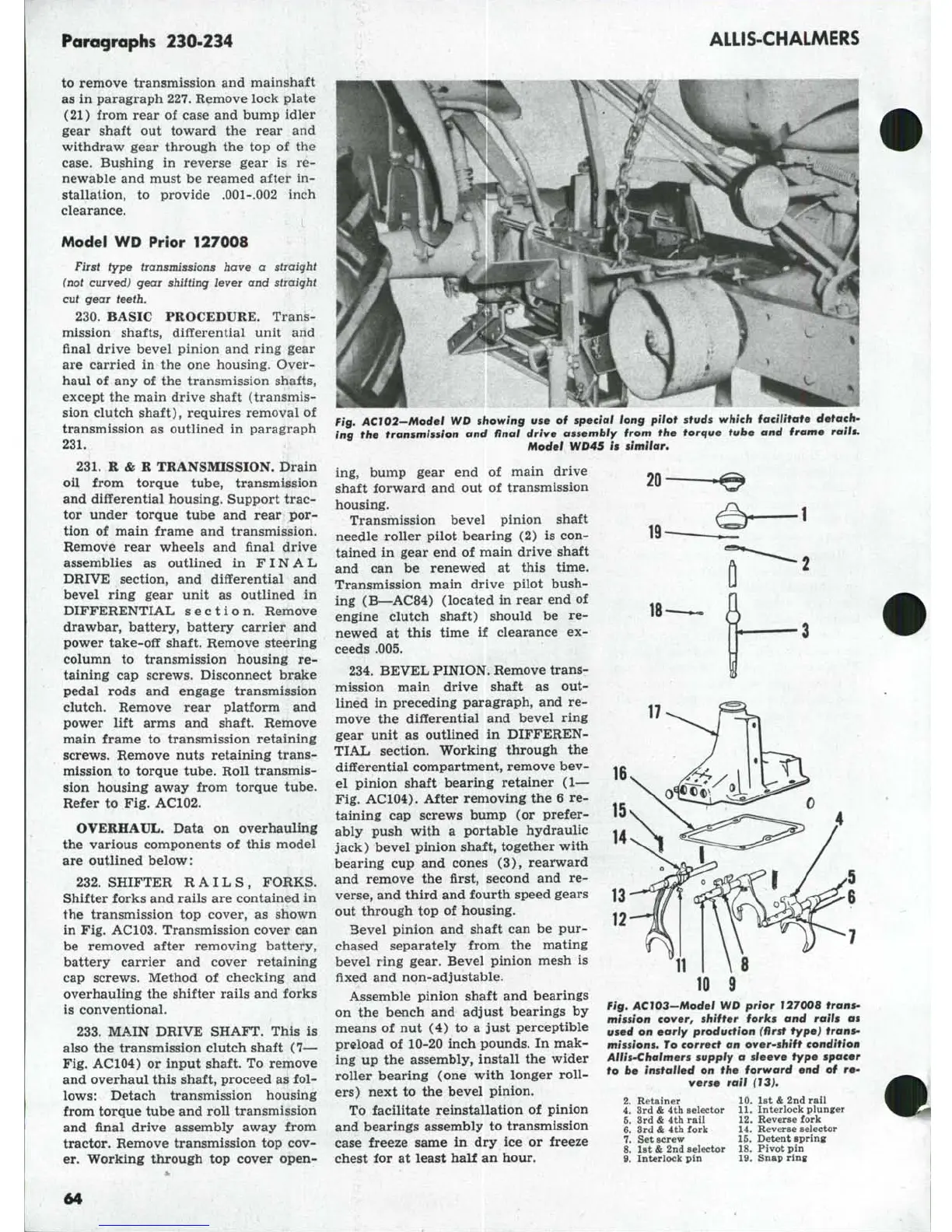

232.

SHIFTER RAILS, FORKS.

Shifter forks and rails are contained in

the transmission top cover, as shown

in Fig. AC103. Transmission cover can

be removed after removing battery,

battery carrier and cover retaining

cap screws. Method of checking and

overhauling the shifter rails and forks

is conventional.

233.

MAIN DRIVE SHAFT. This is

also the transmission clutch shaft (7—

Fig.

AC104) or input shaft. To remove

and overhaul this shaft, proceed as fol-

lows:

Detach transmission housing

from torque tube and roll transmission

and final drive assembly away from

tractor. Remove transmission top cov-

er. Working through top cover open-

16

Fig, AC 102—Model WD showing

use of

special long pilot studs which facilitate detach-

ing

the

transmission

and

final drive assembly from

the

torque tube

and

frame rails.

Model WD45

is

similar.

ing,

bump gear end of main drive

shaft forward and out of transmission

housing.

Transmission bevel pinion shaft

needle roller pilot bearing (2) is con-

tained in gear end of main drive shaft

and can be renewed at this time.

Transmission main drive pilot bush-

ing (B—AC84) (located in rear end of

engine clutch shaft) should be re-

newed at this time if clearance ex-

ceeds .005.

234.

BEVEL PINION. Remove trans-

mission main drive shaft as out-

lined in preceding paragraph, and re-

move the differential and bevel ring

gear unit as outlined in DIFFEREN-

TIAL section. Working through the

differential compartment, remove bev-

el pinion shaft bearing retainer (1—

Fig.

AC104). After removing the 6 re-

taining cap screws bump (or prefer-

ably push with a portable hydraulic

jack) bevel pinion shaft, together with

bearing cup and cones (3), rearward

and remove the first, second and re-

verse,

and third and fourth speed gears

out through top of housing.

Bevel pinion and shaft can be pur-

chased separately from the mating

bevel ring gear. Bevel pinion mesh is

fixed and non-adjustable.

Assemble pinion shaft and bearings

on the bench and adjust bearings by

means of nut (4) to a just perceptible

preload of 10-20 inch pounds. In mak-

ing up the assembly, install the wider

roller bearing (one with longer roll-

ers) next to the bevel pinion.

To facilitate reinstallation of pinion

and bearings assembly to transmission

case freeze same in dry ice or freeze

chest for at least half an hour.

11

10

9

Fig,

AC103-Model WD prior 127008 trans-

mission cover, shifter forks

and

rails

as

used on early production (first type) frons-

missions. To correct

an

over-shift condition

AlliS'Chalmers

supply

a

sleeve type spacer

to

be

installed

on the

forward

end of

re*

verse rail (13),

2.

Retainer

4.

Srd

&

4th selector

5.

3rd

&

4th rail

6. 3rd

&

4th fork

7.

Set screw

8. 1st

&

2nd selector

9. Interlock pin

10.

1st

&

2nd rail

11.

Interlock plunger

12.

Reverse fork

14.

Reverse selector

16.

Detent spring

18.

Pivot pin

19.

Snap ring

64

Loading...

Loading...