15

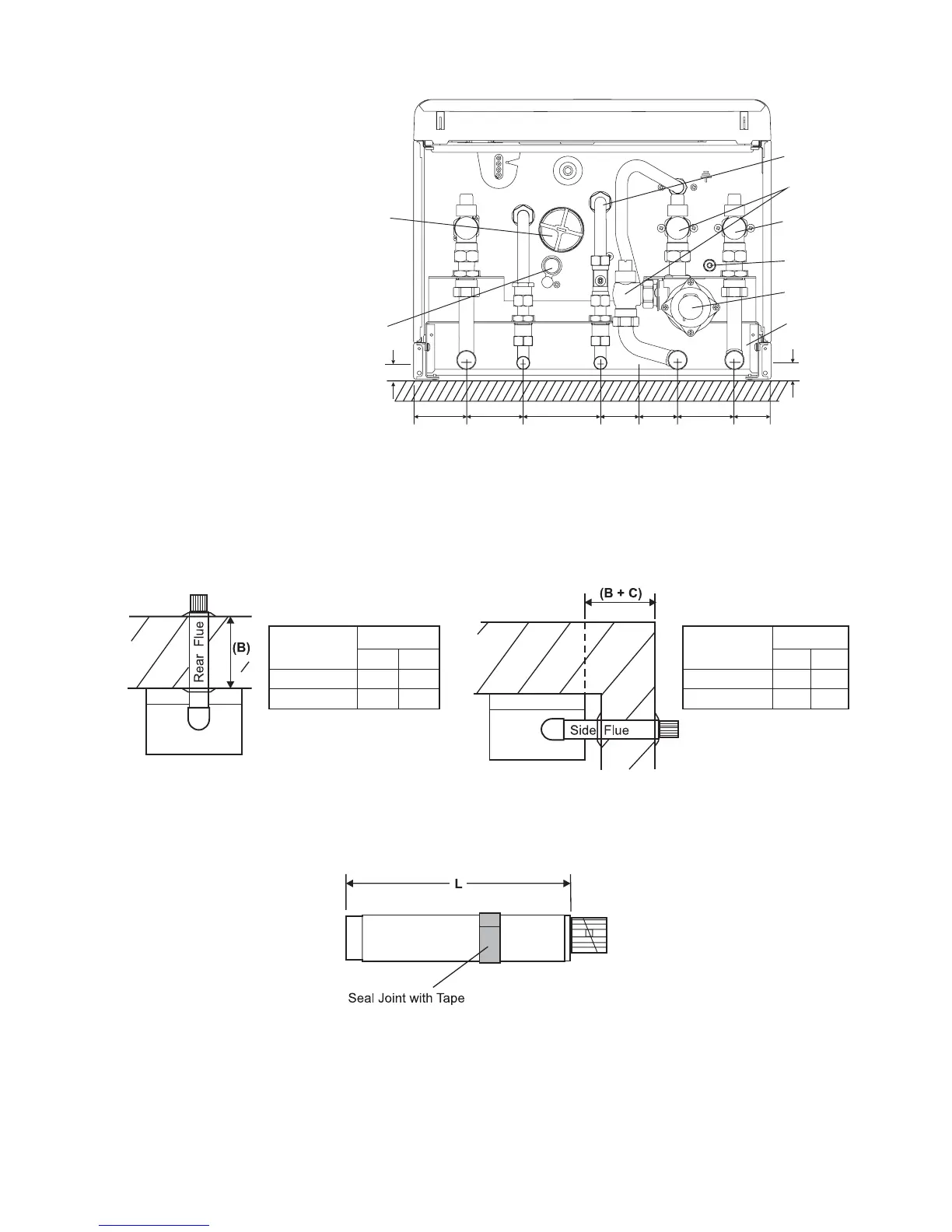

2. Determine the overall length (L) of flue required, (see Fig. 16) as follows:-

Rear flue L = wall thickness (B) + 60 mm

Side flue L = wall thickness (B) + distance between boiler and wall (C) + 120 mm

Fig. 16

3. Adjust the telescopic section of the flue to the distance 'L', ensuring that the two labels marked 'TOP' are aligned, then seal

and secure the joint between the ducts with the sealing tape supplied.

4. Pass the flue assembly through the wall (from inside or outside).

Note: Internal fitting - If there is no access to make good the outside wall, locate the flue sealing collar onto the outer duct

of the flue immediately before the terminal grille onto the location provided. Push the flue assembly through the 130 mm flue

hole, so that the collar completely passes through the wall. Then pull the flue assembly back into the correct position. Visually

check that the collar is sealing the outside wall and that it is not restricting any of the openings of the flue terminal.

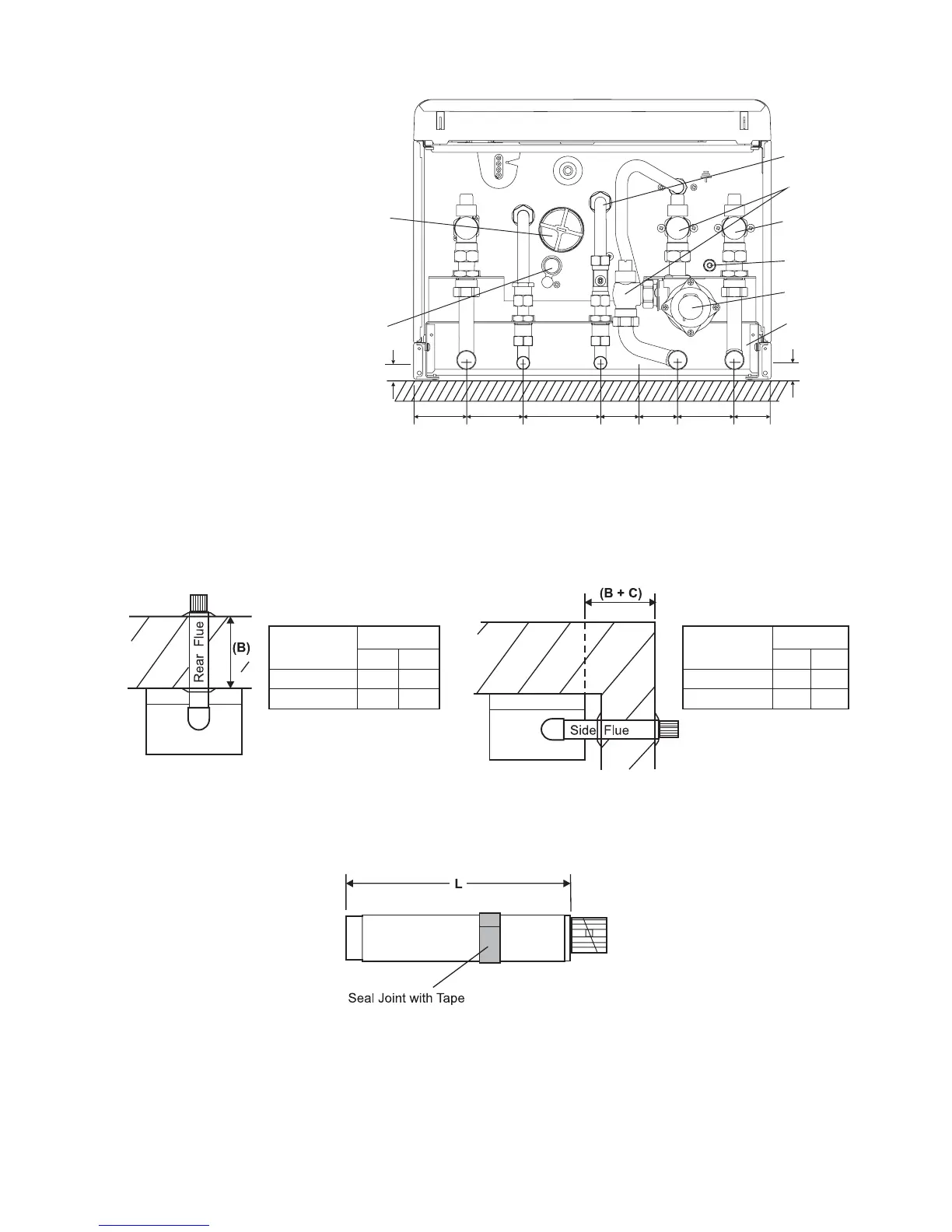

4.6 FIT THE FLUE - Figs. 14, 15

The following procedure applies to fitting an Alpha CD Easy-Flue to both rear or side exit flue - horizontally only.

1. The CD Easy-Flues are suitable for use in the flue length ranges shown in the tables below.

Note: Where the length is less than the minimum or more than the maximum, refer to Section 4.7.

Alpha CD25X/28X - Installation

Fig. 14 Fig. 15

CD Easy-Flue

500 mm

1000 mm

B (mm)

Max

550

945

Min

310

705

CD Easy-Flue

500 mm

1000 mm

Max

465

860

Min

225

620

B + C (mm)

Note: Add 40 mm to

dimension B if the wall jig is

used.

Fig. 13b - With wall jig

A - Heating flow (22 mm)

B - Hot water outlet (15 mm)

C - Gas inlet (22 mm)

D - Cold water mains inlet (15 mm)

E - Heating return (22 mm)

F - Pressure relief valve (15 mm)

Loading...

Loading...