36

Alpha CD25X/28X - Fault Finding

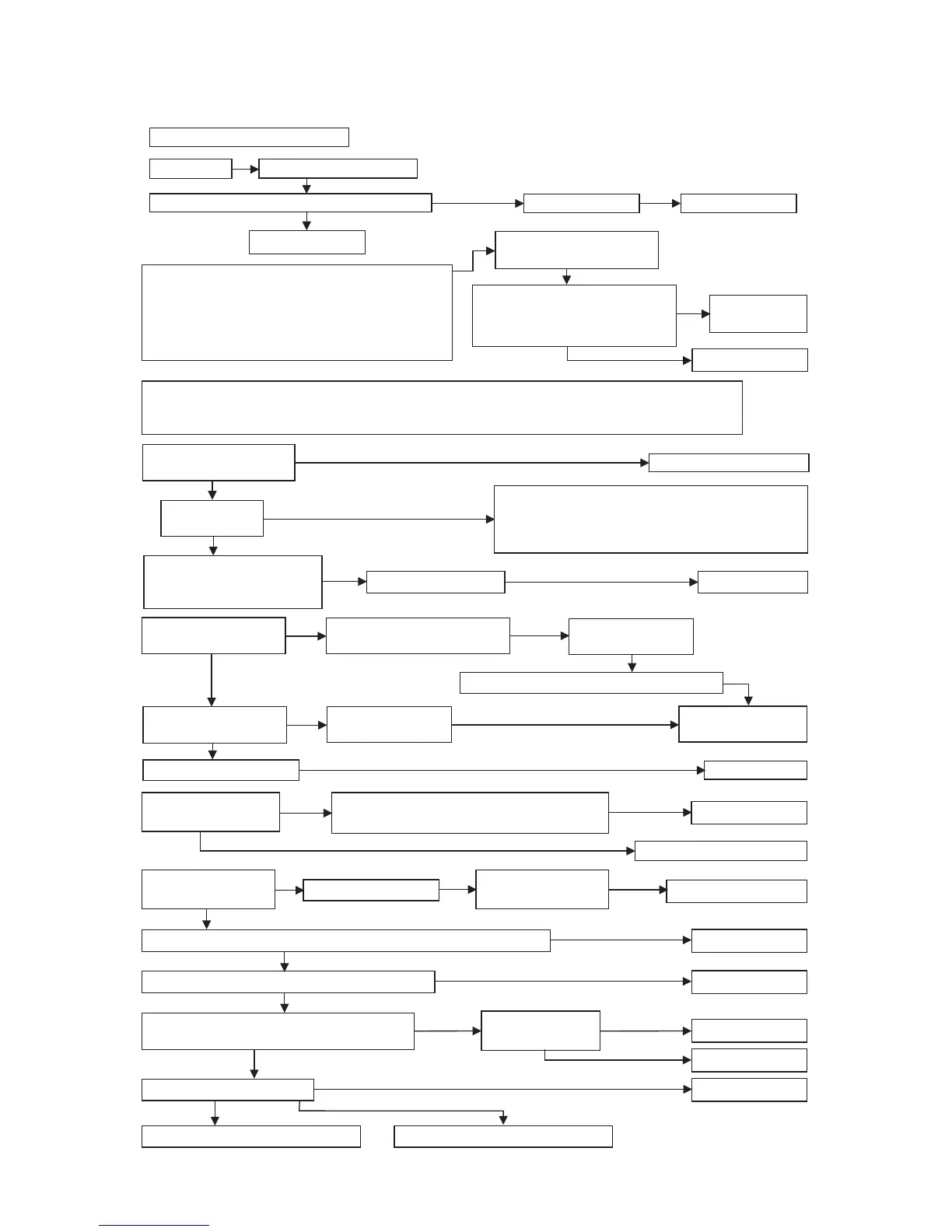

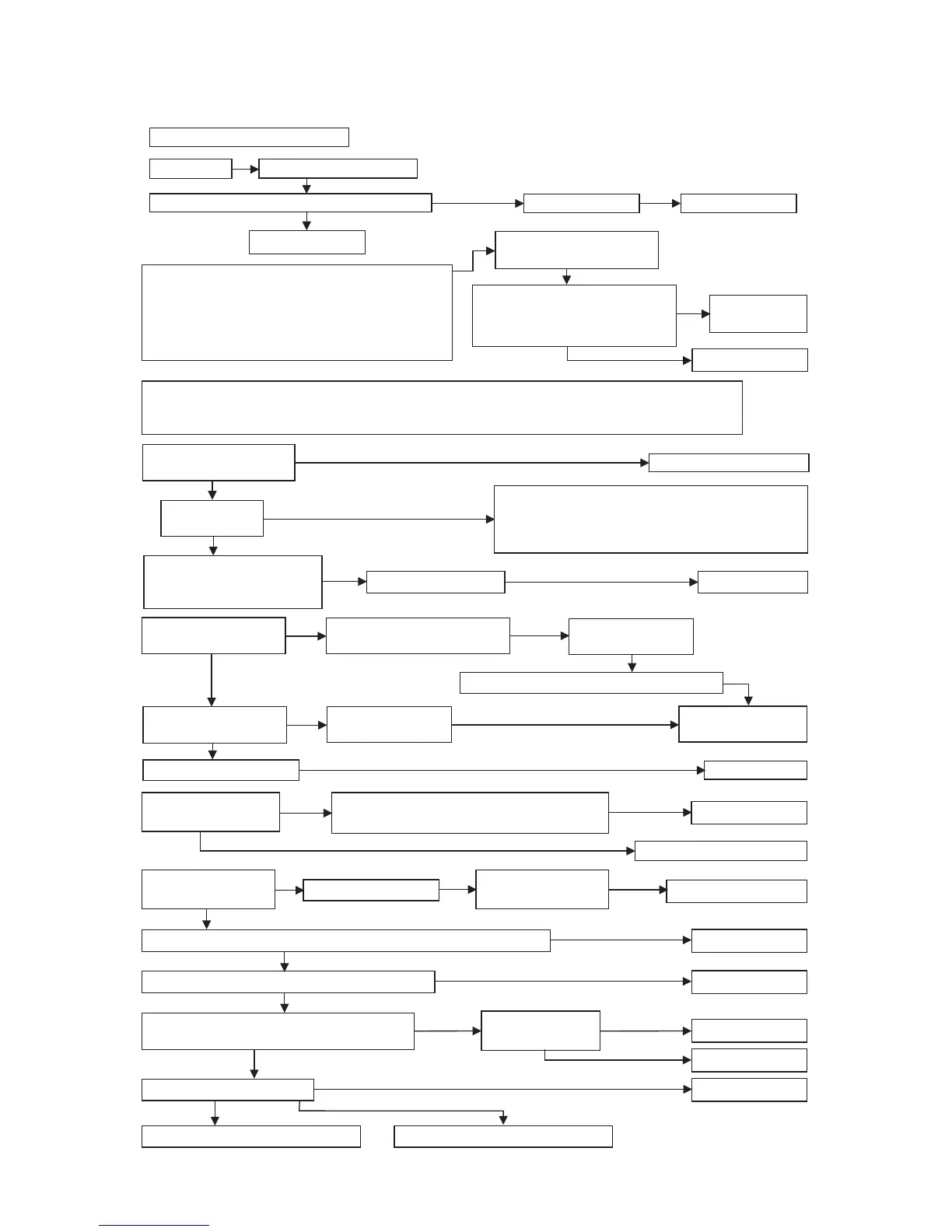

10.5 FAULT FINDING SOLUTIONS E to K

NO

Check and correct:-

1. Ignition electrode and lead

2. Electrode connections

3. Spark gap and position

4. Connections at ignition generator and PCB connector X8

5. Blocked flue

F

Is spark generator (T2)

making a clicking noise

Disconnect the plug from

the spark generator.

PCB, X8 connector is 240V ac

across terminals 2, 3 during ignition

Replace PCB

Replace ignition

generator

YES

NO

YES

NO

YES

240V at internal clock

terminals 1 and 2

I

240V at PCB - X12 connector,

terminals 5 and 1

240V at PCB - X12 connector, terminals 5 and 1

Wiring between clock

and PCB is correct

YES

YES

NO

YES

Continuity across

clock terminals 3 and 4

Internal clock calling for heat

Wiring between clock

and PCB is correct

Replace clock

Check external controls

are calling for heat

YES

YES

NO

J

Replace primary pressure switch

Replace PCB

Continuity across primary

pressure switch terminals

Unplug leads from primary pressure switch

5 V DC at PCB across X9 connector terminal 1 and 3

YES

NO

NO

YES

YES

YES

YES

YES

YES

Replace PCB

Replace PCB

Replace lead

Replace motor

Replace valve

Replace DHW flow switch

Continuity across DHW

flow switch (hot tap on)

Diverter valve spindle operating

Check DHW heat exchanger for blockage

Check by-pass valve is not stuck open

36 V DC at PCB across X4 connector terminal 3 and X13 connector terminal 3

240 V AC at PCB across X15 connector terminals 4, 5

Remove the diverter valve motor, is the brass piston

fully extended (flush with plastic housing)

Flow rate above 2.5l/min

Check mains supply.

Clean mains inlet filter

Check continuity of

motor plug and lead

NO

NO

YES

NO

NO

NO

NO

NO

NO

K

G

Check and correct:-

1. Pressure tubes are connected and not blocked

2. If explosive ignition, check wiring to ignition generator is correct

3. Polarity

4. Flame sensing electrode and lead connections

5. Electrode position

E

Check pressure tubes are connected

PCB - X3 connector, is 240 V across terminals 1, 2

YES NO

Gas at burner

Replace gas valve

Adjust gas valve

NO

NO

Ensure gas is on and purged

Replace PCB

H

NO

NO

Allow to cool. Continuity

across thermostat terminals

NO

YES

YES

Air in main heat exchanger.

Blocked heat exchanger/pipework

or pump not circulating water

Vent air, clear blockage

Replace pump

Continuity across

thermal fuse

Replace overheat thermostat

Replace heat exchanger - t remove the thermal fuse.

It is important to find the exact

cause of the overheat and rectify it before

operating the boiler with the new heat exchanger

Do no

Note:

Loading...

Loading...