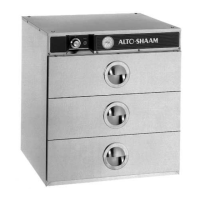

WARMING CABINET CHARACTERISTICS

The cabinet is equipped with a special, low-heat-density,

heating cable. Through the HALO HEAT concept, the heat-

ing cable is mounted against the walls of the warming com-

partment to provide an evenly applied heat source controlled

by a thermostat. The design and operational characteristics

of the cabinet eliminates the need for a moisture pan or a heat

circulating fan. Through even heat application, the quality of

a food product is maintained up to as much as

several hours.

THERMOSTAT AND

PILOT LIGHT SEQUENCE

Whenever the thermostat is turned up, the pilot light will

indicate the power ON/OFF condition of the heating cable,

and consequently, the cycling of the cabinet as it maintains

the dialed cavity temperature. If the pilot light does not indi-

cate after normal start-up, the main power source, thermo-

stat, and/or the pilot light must be checked. If a warming

compartment does not hold the temperature as dialed, the

calibration of the thermostat must be checked. (See the para-

graph on thermostat calibration.) If a warming compartment

fails to heat or heats continuously with the thermostat OFF,

the thermostat must be initially checked for proper operation.

If all is in order, a continuity and resistance check of the heat-

ing cable should be made. (See the circuit

diagram.)

THERMOSTAT CALIBRATION

The thermostat is precision calibrated at the factory.

Normally, no adjustment or recalibration is necessary unless

the thermostat has been mishandled in transit, changed or

abused while in service. A thermostat with a sensing bulb

operates on hydraulic pressure. Consequently, any bending

of the bulb results in a change in its volume and displaces the

accuracy of the thermostat calibration.

A thermostat should be checked or recalibrated by plac-

ing a quality temperature indicator at the center of an empty

warming cavity. DO NOT CALIBRATE WITH FOOD PROD-

UCT IN THE WARMING CABINET. The temperature must

be allowed to stabilize at one particular setting for at least

one hour. Following this stabilization period, the center of

the thermal swing of the cavity temperature should approxi-

mately coincide with the thermostat setting.

The calibration screw of the thermostat is located in the

dial shaft, and should be adjusted with great care and cau-

tion. With the shaft held stationary, a minute clockwise

motion of the calibration screw APPRECIABLY lowers the

thermostat setting while a reverse, counter-clockwise motion

results in the opposite condition. After achieving the desired

cycling of the thermostat, the calibration screw must be

sealed in place with a few drops of sealant.

[RED NAIL POLISH OR EQUIVALENT IS ACCEPTABLE.]

QUANTITY ALTO-SHAAM

10/13/98 PART DESCRIPTION PER UNIT PART NO.

1. TOP 1 11369

2. TOP MOUNTING SCREWS 4 SC-2459

3. POWER CORD (125V) 1 CD-3232

CORD SET: 230V INTL (TYPE HO7 RN-F) 1 CD-3984

CORD SET: 208-240V) 1 CD-3858

4. POWER CORD STRAIN RELIEF BUSHING

(125V) 1 BU-3011

INLET (208-240V) 1 IT-3857

INLET (230V) 1 IT-33173

5. CASING BACK 1 11380

6. CASING BACK MOUNTING SCREWS 2 SC-2459

7. DRAWER ASSB. 1 5303

DRAWER ASSB. W/VENTS (

OPTION - NOT SHOWN) 1 15418

EACH ASSEMBLY INCLUDES:

— DRAWER PULL 1 PL-2005

— PAN SPACERS 2 11398

— PAN SPACER MOUNTING SCREWS 4 SC-2459

— DRAWER BEARINGS 4 BG-2410

8. DECOR PANEL (125V) 500-1D 1 5744

DECOR PANEL (208-240V) 500-1D 1 5743

9. WATTAGE SWITCH (125V only) 1 SW-3409

10. THERMOSTAT 1 TT-3057

11. HEAT INDICATOR LIGHT (125V) 1 LI-3027

HEAT INDICATOR LIGHT (208-240V,230V) 1 LI-3951

12. TEMPERATURE GAUGE 1 GU-33384

13. CASING ASSEMBLY 1 4336

14. INSULATION: 22" x 43" (559mm x 1092mm) 1 IN-2381

15. CABLE CONNECTION HARDWARE

16. FAN (125V) 1 FA-3485

FAN (208-240V,230V) 1 FA-3342

FAN BLADE 1 FA-3343

17. HEATING CABLE: Length 104' (31699mm) 1 CB-3044

18. CABINET DRAWER RAIL ASSEMBLY

(

NOT SHOWN) 1 5331

19. CABINET DRAWER RAIL ASSEMBLY

MOUNTING STUD (

NOT SHOWN) 4 ST-2547

20. CABINET DRAWER RAIL ASSEMBLY

MOUNTING NUT (

NOT SHOWN) 4 NU-2437

21. CABINET DRAWER BEARINGS (

NOT SHOWN) 2 BG-2410

22. DRAWER PAN (

NOT SHOWN) 1 PN-2123

O PERATION AND C ARE M ANUAL #818 • 3

DISCONNECT UNIT FROM POWER

SOURCE BEFORE CLEANING

OR SERVICING

SERVICE VIEW PARTS LISTS

MODEL 500-1D

Loading...

Loading...