ANSUL INCORPORATED, ONE STANTON STREET, MARINETTE, WI 54143-2542 715-735-7411 Form No. F-2001263 ©2001 Ansul Incorporated Litho in U.S.A.

System Components

UL EX-4510 12-1-01 Page 1-15

Description

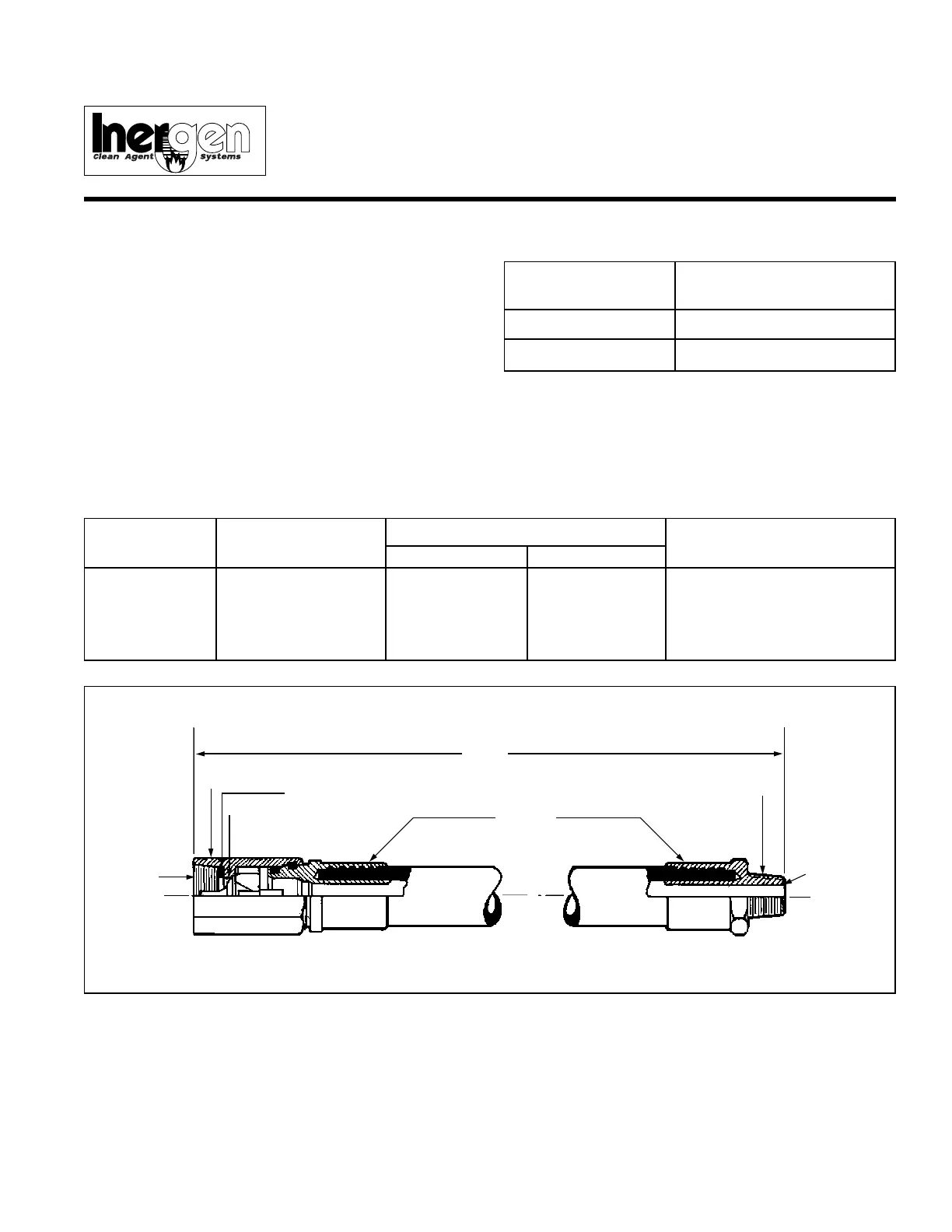

The valve Flexible Discharge Bend (Part No. 427082) is a

5/8 in. (1.59 cm) I.D. extra-heavy flexible hose which con-

nects the valve discharge outlet to the fixed piping or head-

er manifold. The discharge bend has a special female

thread for connecting to the valve outlet and a male 1/2 in.

NPT thread for connecting to the fixed piping or manifold.

The discharge bend will withstand a pressure of 9000 psi

(621 bar). Its flexible connection allows for easy alignment

of multiple cylinder banks to fixed piping. Each bend has a

built-in check valve that prevents loss of agent should the

system discharge while any cylinder is removed.

The equivalent length of this hose is equal to 18 ft. (5.5 m)

of 1/2 in. Sch. 40 pipe.

ANSUL and INERGEN are trademarks of Ansul Incorporated or its affiliates.

Flexible Discharge Bend

Shipping Assembly

Part No. Description

427082 Flexible discharge bend

842430 Washer

Thread Size/Type

Component Material Valve End Manifold End Approvals

5/8 in. Flexible SAE 100 R2 Special to 1/2 in. NPT Male UL Listed (EX-4510)

Discharge Bend Type AT mate with

CV90 and

CV-98 Valve

18 7/8 IN.

(47.9 cm)

MANIFOLD/END

000658

1/2 IN. NPT

MALE COUPLING

FEMALE ADAPTOR

(BRASS)

VALVE END

CHECK

WASHER

SWAGE ON

ANSUL

®

Loading...

Loading...