7

Mist Applicator recommended maintenance: Check: Cup gasket, nozzle gasket, gland seal, air cap holes, nozzle/needle

assembly every 50 hours or when necessary. Clean or replace parts as needed. Mist Applicator maintenance kit part

#A5256.

TROUBLESHOOTING

1.Solution cup full, motor unit air is supplied to the Mist Applicator. Trigger is pulled and no solution comes out—Reason:

Cup not pressurizing.

Check:

A) Air Feed Tube/one way air valve (#25) A.5232

B) Air Feed Connector (#8) (A.5211)

C) Cup is screwed on tight

D) Cup top gasket is not damaged.

2. When Mist Applicator is connected to a turbine and the turbine is on, air continually flows through the air cap even if

the trigger is not pulled. Response: This is correct, “bleeder” type Mist Applicators are necessary and desirable to

ensure longevity of the motor unit.

3. If you think that you are getting too much “overspray”

Try: Moving the Mist Applicator closer to the work

Closing down the fluid flow

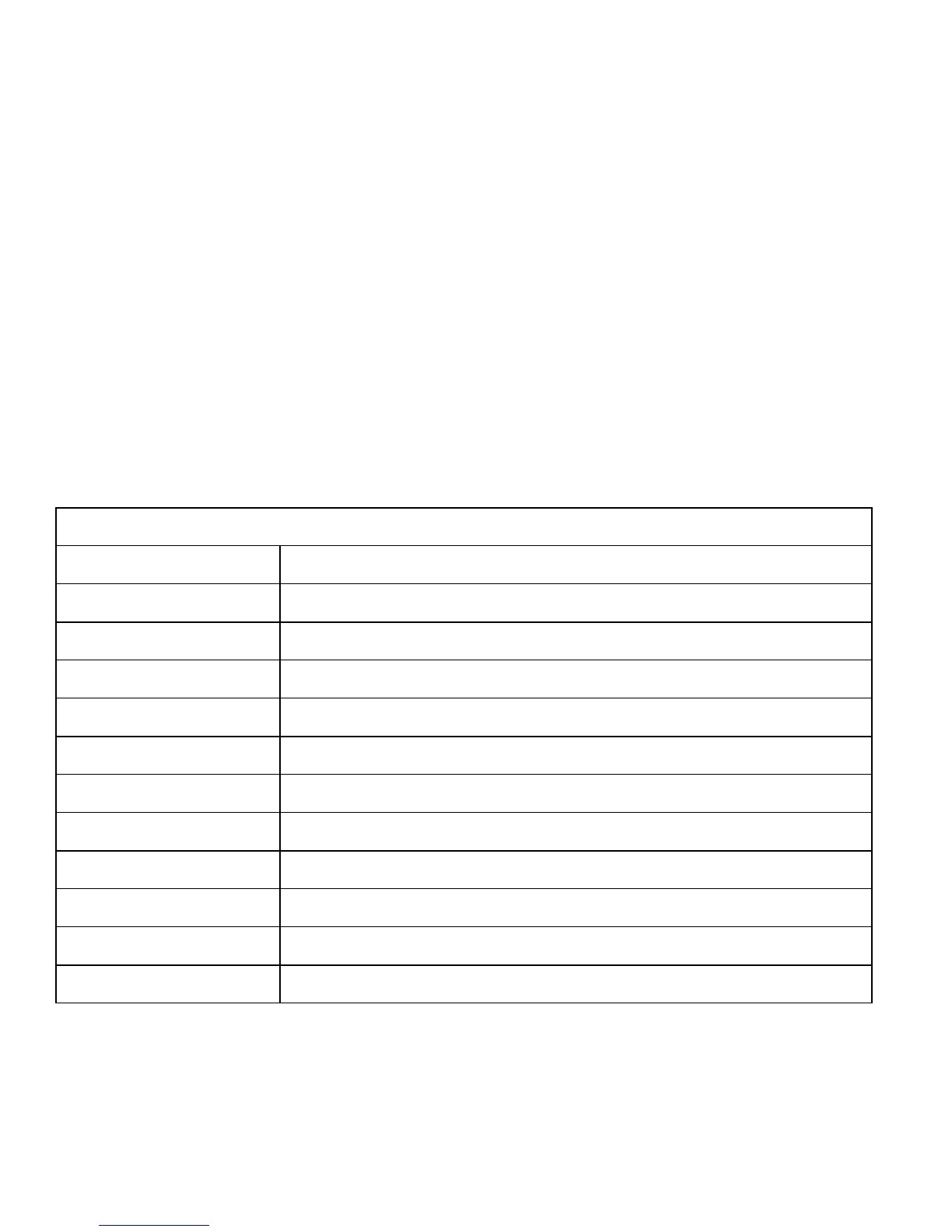

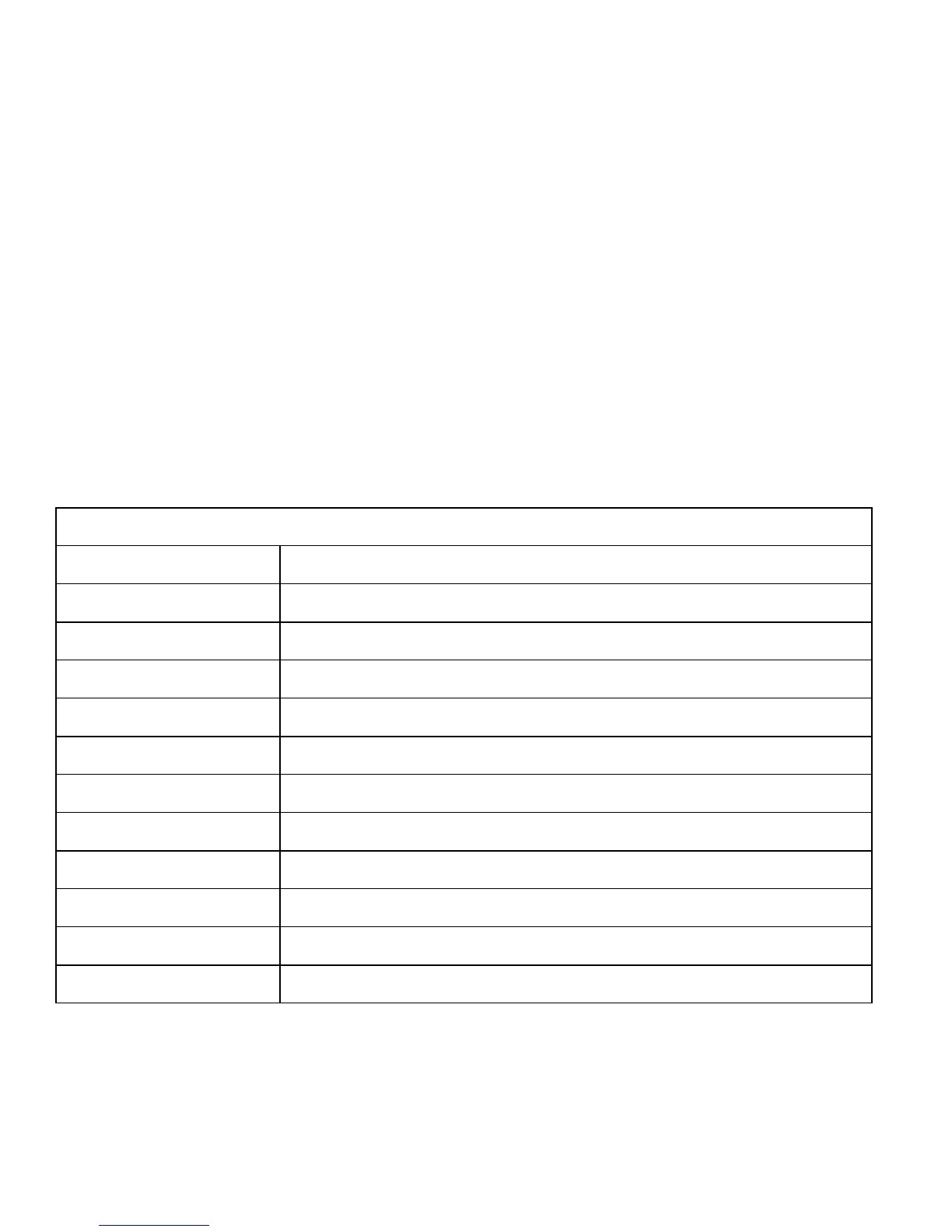

RECORD OF MIST APPLICATOR MAINTENANCE

DATE MAINTENANCE PERFORMED

Mist Applicator recommended maintenance: Check: Cup gasket, nozzle gasket, gland seal, air cap holes, nozzle/needle

assembly every 50 hours or when necessary. Clean or replace parts as needed. Mist Applicator maintenance kit part

#a.5256

Loading...

Loading...