Do you have a question about the Arjohuntleigh Malibu Sovereign and is the answer not in the manual?

| Brand | Arjohuntleigh |

|---|---|

| Model | Malibu Sovereign |

| Category | Lifting Systems |

| Language | English |

Tasks and checks to be performed by the caregiver.

Maintenance tasks for qualified personnel, with service procedures and page references.

Verifies if the latest Field Safety Notices or Technical Advisory Notices are applied.

Inspects lift arm, safety catch, tub, mixer unit, and cabling for damage.

Checks lift arm, safety catch, drain, tub, actuators, air jets, and chassis.

Inspects inlet hoses, mixer, MPA hoses, and drain for leaks or damage.

Procedure to check and clean the incoming water filter.

Inspects RPE solenoid valves and old solenoid fill valves for proper function.

Tests water flow and pressure to check/replace flow restrictors in fill and pump valves.

Adjusts or replaces mixer cartridges for temperature and flow regulation.

Tests electronic scalding protection for fill, shower, and tub functions.

Adjusts mechanical scalding protection for fill and shower temperatures.

Verifies correct disinfection dosage and flow rate.

Inspects and replaces parts of the shower/disinfection handle for flow and leaks.

Lubricates chassis and lift arm components as per specifications.

Verifies the function of the safety cut-out switch on the lift arm.

Tests the potential equalization and earth resistance of the unit.

Tests the control box batteries under load conditions.

Conducts a final service check of all functions and indicators.

Tests the functionality of the emergency stop button on the tub.

Checks and replaces the safety catch mechanism on the lift arm.

Conducts a test to verify the safe working load capacity of the hoist.

Reads and notes the number of strokes performed by the lift arm actuator.

Inspects castors for wear, movement, appearance, and brake function.

Procedure for replacing the safety belt on the chair.

Steps to remove and replace the filter in the air blower unit.

Replaces air jet caps and diaphragms for the Air Spa system.

Recommends replacing pressurized water connection hoses every five years.

Procedure for replacing the batteries in the control box.

Detailed steps for removing and replacing the actuator in the lift arm.

Instructions for replacing the Printed Circuit Board in the outer profile.

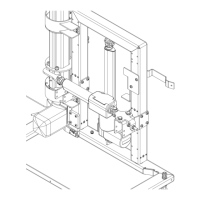

Steps for removing and installing a new MPA pump.

General guidance for repairing separated parts/brackets using adhesive.