50-60 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Form No.V8700R1

Page 2 of 4

SPECIFICATIONS

Force Output: 250 lbs

Stroke: 1 1/8I

Electrical Characteristics:

Operating

Amperes (nominal)

Voltage *

Inrush Running Holding

24V/50-60Hz

120V/50-60Hz

240V/50-60Hz

28.00

5.60

2.80

8.00

1.85

0.92

0.73

0.11

0.05

*50 Hz construction increases opening time 20%.

Opening Time: Fast Opening: 6 to 14 seconds

Slow Opening: 14 to 26 seconds

Note: Opening time doubles between -30_F to -40_F

(-34_C to -40_C). Timing not field adjustable.

Maximum Closing Time: One second

Temperature Limitations: Ambient -40_F to 150_F

(-40_C to 66_C)

Damper Arm Rating: Drives damper in one direction only.

20 lb maximum at 2.85 in. radius at 20_F to 150_F

(-7_C to 65_C ) and 10 lb maximum at -40_F to 20_F

(-40_C to -7_C).

Damper Arm Travel: 2I maximum

INSTALLATION

Before installation, check nameplates to verify actuator and

valve selected are appropriate for the application.

IMPORTANT: After actuator installation, test all functions

and check out complete system before putting actuator/valve

into service.

Positioning/Mounting

Follow the V710 Series Gas valve and/or damper

manufacturer's instructions when installing the Hydramotorr.

1. AH2D actuators can be installed to operate in any

position.

2. Position the actuator to operate the valve (and damper if

appropriate), and secure with the two mounting set screws

(Figure 2). Torque set screws to 80 ± 5 in-lbs

[9,0 ± 0,5 Nm] using a 5/32I hex key wrench.

3. For damper applications requiring the damper arm to

return upon power failure, the optional return spring and

spring plug (kit 440006) must be installed on the damper

arm. Connect linkage so that damper returns to the

desired position.

Wiring

WARNING: Electrical hazard. To prevent the

possibility of death, serious injury or property

damage, open circuit before inspection, service or

disassembly. Reassemble before operating.

Wiring must comply with local codes and the National

Electrical Code. Limit controls must conform to actuator

rating (voltage, amperage, hertz). Wire limit controls to the hot

side of power supply.

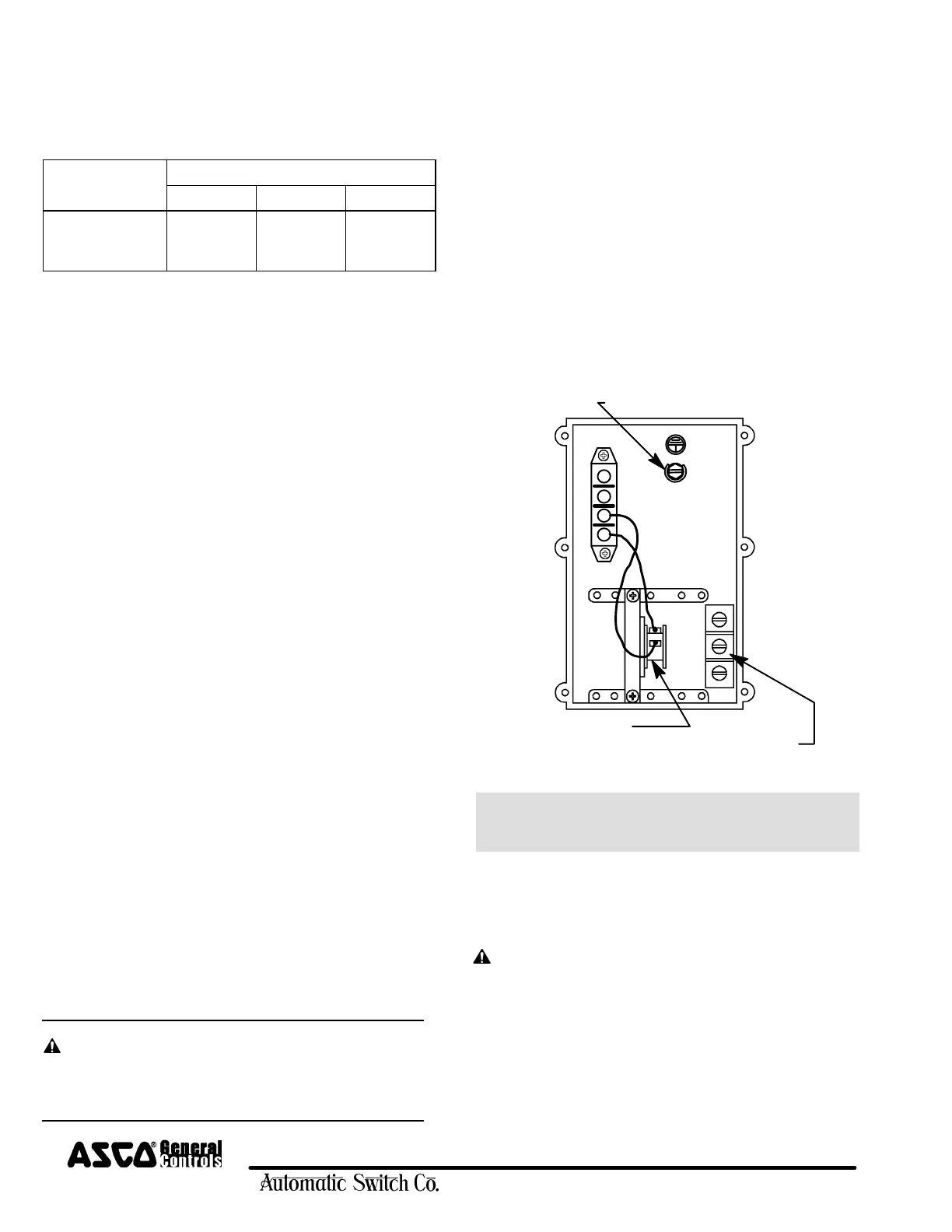

1. Remove six screws and electrical cover.

2. Route wiring through one of the conduit knockout

openings. Install appropriate electrical fittings.

3. Connect the power wiring to terminals N (neutral) and L1

(hot). A green grounding screw with a cup washer is

provided beside the terminal strip for grounding.

(Figure 3).

4. Torque terminal screws to 8-12 in-lbs [0,9-1,3 Nm].

5. Connect auxiliary or valve overtravel proof-of-closure

switch wiring to the common and normally open or

normally closed switch terminals (Figure 3).

6. Reinstall electrical cover on actuator housing.

7. Operate system through five cycles to verify proper

operation.

Figure 3. Typical AH2D Actuator Wiring.

NC

NO

COMM

Travel limit switch

Auxiliary or overtravel proof-of-closure switch

Grounding screw with cup washer

N

L1

1

2

3

4

LINE VOLTAGE

C

NO

Auxiliary and Overtravel Proof-of-Closure

Switch Ratings

15 Amps 120 Vac

7.5 Amps 240 Vac

Total connected load of auxiliary and overtravel

proof-of-closure switches not to exceed 1800 VA.

CAUTION: Overtravel Proof-of-closure switch

must only be used with V710 Series Gas Valves

having an overtravel seal (V22 or V25 Suffix in catalog

number).

Overtravel Proof-of-Closure Switch

The optional valve overtravel proof-of-closure switch is set at

the factory to provide both a mechanical and electrical means

of proving valve closed position interlock to the primary

control. This switch is not to be field adjusted.

Loading...

Loading...