Page 3 of 4Form No.V8700R1

50-60 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

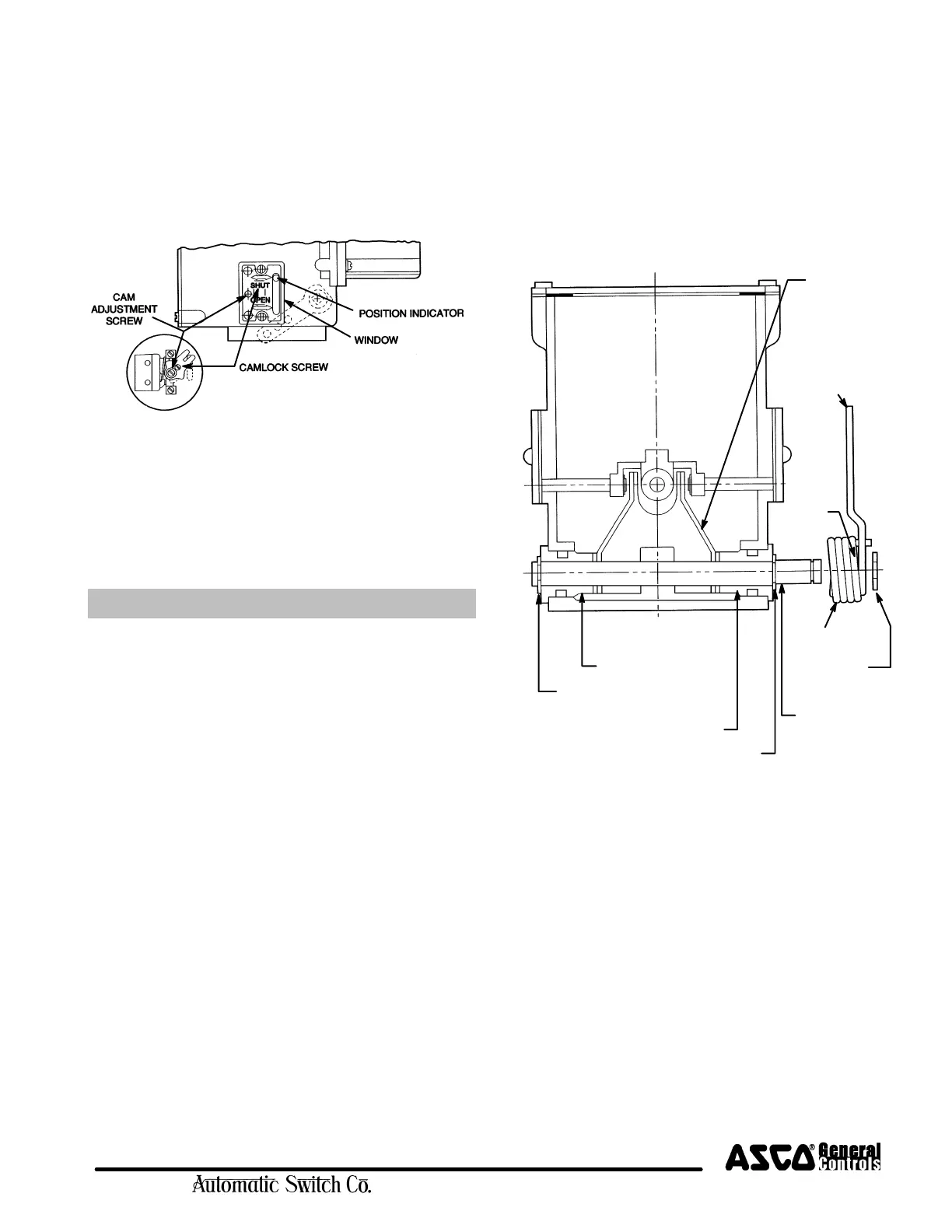

Auxiliary Switch Adjustment

1. Remove the window (Figure 4).

2. Loosen the camlock screw no more than 1/2 turn.

3. Reset the cam adjustment screw to the desired switching

point.

4. Tighten the camlock screw. Cycle the actuator to verify

the switch setting and readjust as required.

5. Reinstall the window and torque screws evenly to 14-16

in-lbs [1,6-1,8 Nm].

Figure 4. Auxiliary Switch Adjustment

MAINTENANCE

Maintenance should include periodic inspection and cleaning.

Use a cleaning fluid compatible with actuator components to

remove dirt and oil. Organize a maintenance schedule based

on environment and frequency of use. Check for loose

electrical and mechanical connections and replace damaged

lead wires.

Field Service Notice

Field service replacement kits are limited to the following:

1. Travel limit switch Replacement Kit 440000 (AH2D).

2. Left-hand auxiliary switch Replacement Kit 440002.

3. Right-hand auxiliary switch Replacement Kit 440003.

4. Overtravel proof-of-closure switch Replacement Kit

440004. See separate AH series actuator overtravel

proof-of-closure switch replacement kit installation

instructions.

5. Damper shaft Replacement Kit 440005.

6. Damper arm Replacement Kit 440006 (with spring and

spring plug) or 440007 (without spring and spring plug).

7. Oil Replacement Kit 440008.

To order, specify the kit or part number, as well as the actuator

model and serial numbers.

Travel Limit Switch Replacement

1. Remove the six cover screws and the cover plate

(Figure 1)

2. Disconnect actuator and switch wiring. Remove two

mounting screws and the limit switch (Figure 2).

3. Install the new switch and reconnect wiring. The required

stroke is 1 1/8I ± 1/16I. Turn adjustment screw located

above limit switch until the desired stroke is achieved.

Turn the adjustment screw clockwise to decrease stroke

and counterclockwise to increase stroke. Operate the

actuator a few times to verify proper adjustment.

4. Reinstall the cover plate and screws.

Auxiliary Switch Replacement

1. Remove six cover screws and the cover plate (Figure 1).

2. Disconnect switch wiring. Remove two mounting screws

and old switch wiring and install new switch.

3. Wire and adjust switch as instructed under Switch

Adjustment.

4. Install actuator on valve and torque set screws to 80 ± 5

in-lbs [9,0 ± 0,5 Nm] using a 5/32I hex key wrench.

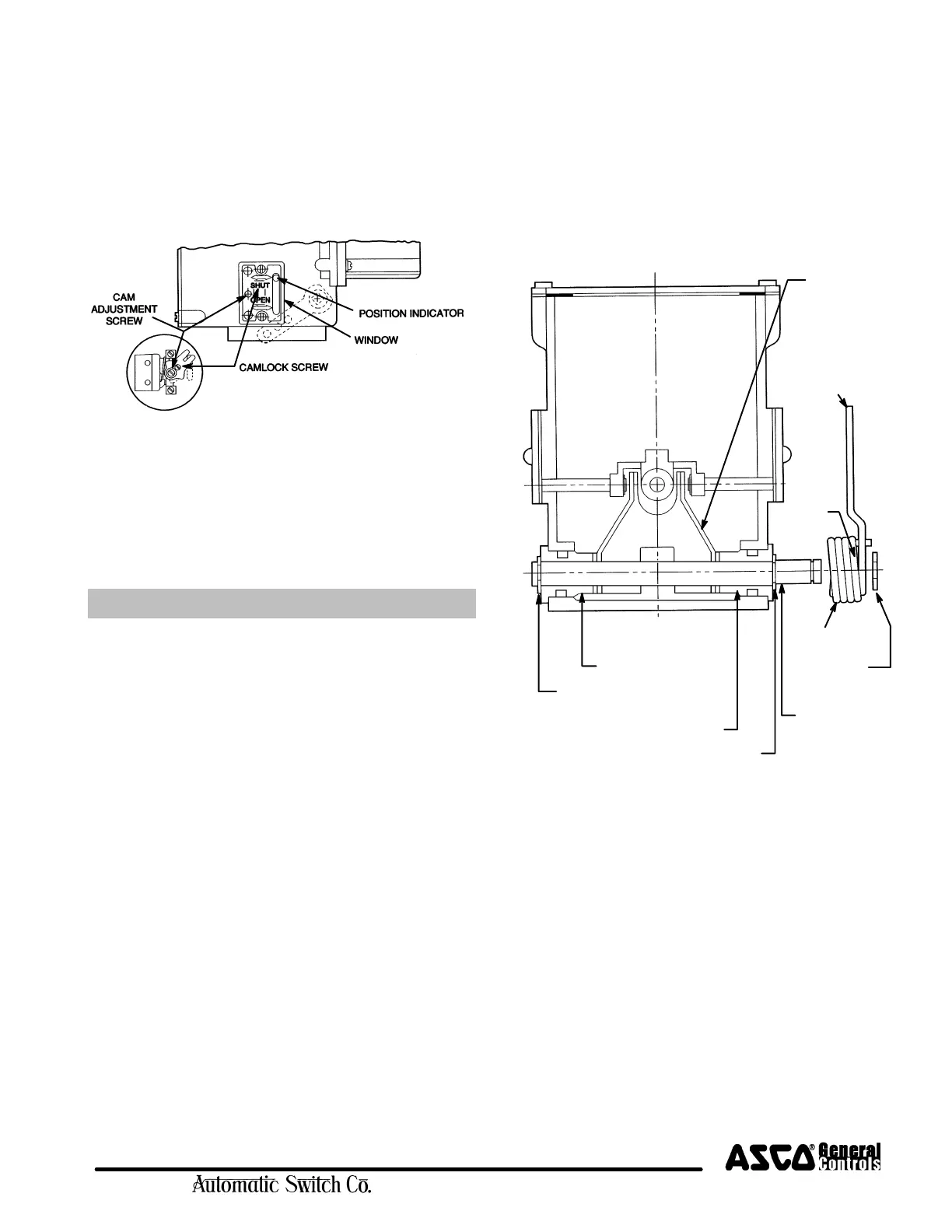

BUSHING (2)

RETAINING RING (1)

DAMPER

RETAINING

RING (6)

SHAFT (3)

RETAINING

RING (6)

SPRING (8)

SPRING

PLUG (9)

DAMPER

DAMPER ARM

POSITIONER (4)

ARM (7)

Figure 5. Damper Shaft and Damper Arm Kits

BUSHING (5)

Damper Shaft Installation (Figure 5)

The damper shaft can be installed with the damper arm on

either side of the actuator.

1. Loosen the two mounting set screw (Figure 2) and lift the

actuator from the valve.

2. Install the retaining ring (1) and bushing (2) on the

damper shaft (3).

3. Install the damper arm positioner (4), then slide the

damper shaft (3) through the actuator and positioner.

4. Install bushing (5) and secure with retaining ring (6).

5. Reconnect the wiring, restore power, and cycle the

actuator to verify proper operation.

Loading...

Loading...