ASCON TECNOLOGIC - TLZ 20

-

OPERATING INSTRUCTIONS - Vr. 02 – ISTR-MTLZ20IEFD02 - PAG. 5

transformer TCTR, or with equivalent features, and to use only one

transformer for each instrument because there is no insulation between supply

and input. We recommend that a check should be made that the parameters

are those desired and that the application functions correctly before

connecting the outputs to the actuators so as to avoid malfunctioning that may

cause irregularities in the plant that could cause damage to people, things or

animals.

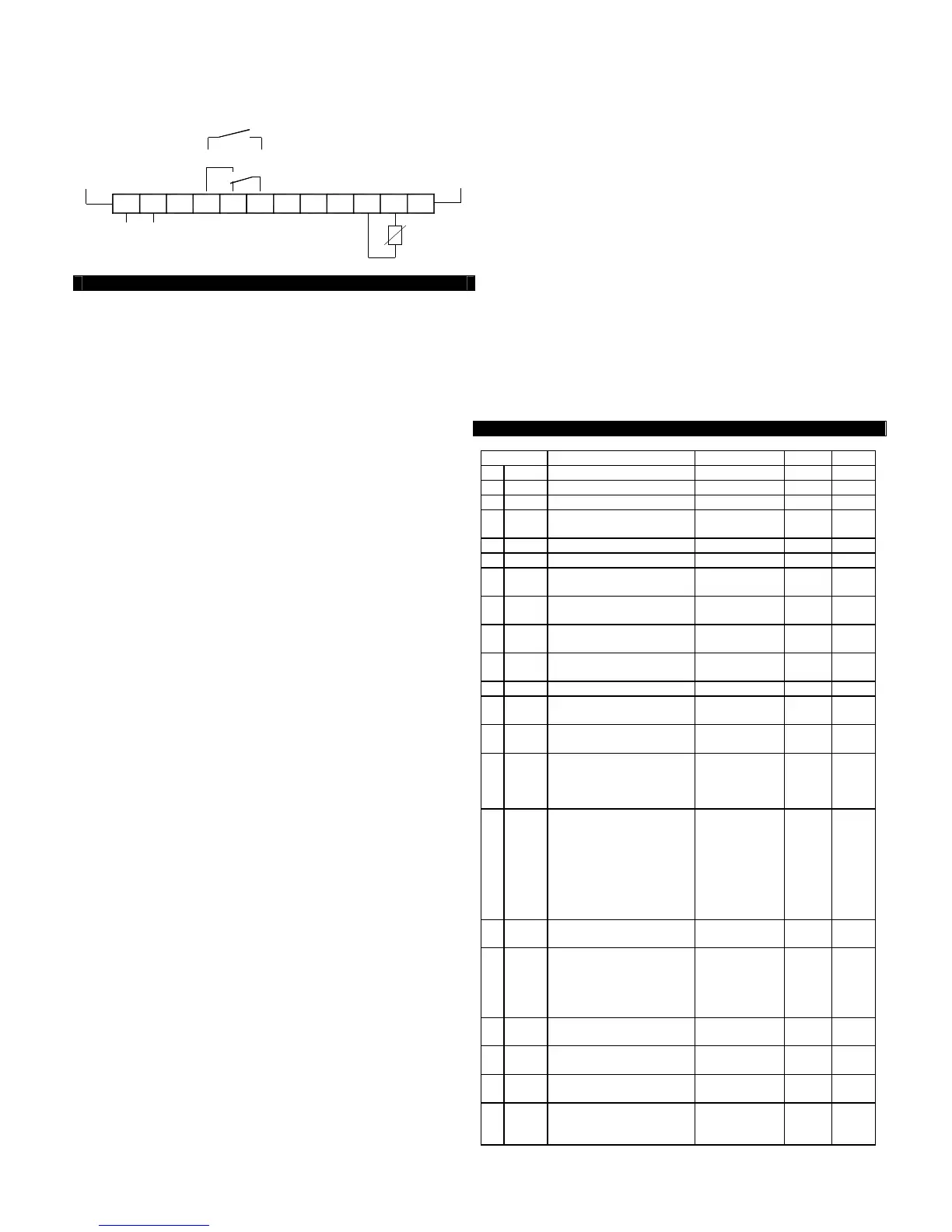

S U P P L Y

P T C -N T C

21

T L Z 2 0

CN CN O

O U T

53 4 76

S P D T 1 6 A -A C 1

N O

C

S P S T -N O 1 6 A - A C 1

IN P U T

1 08 9 1 21 1

P R O B E

4 - FUNCTIONS

4.1 - MEASURING AND VISUALIZATION - Via the parameter “SEnS” it is

possible to select the type of probes that one wishes to use and which can be:

thermistores PTC KTY81-121 (Ptc) or NTC 103AT-2 (ntc). Once the type of

probe used has been selected, through the parameter “Unit”, it is possible to

select the temperature unit of measurement (°C or °F) and, through the

parameter “dP”, the resolution of the desired measurement (OFF=1°; On

=0,1°). The instrument allows the measuring to be calibrated, that can be used

for re-calibrating the instrument according to application needs, through the

parameters “OFS”. Using the parameter “FiL”, it is possible to set the time

constant for the software filter for measuring the input values to be able to

reduce the sensitivity to measurement disturbances (increasing the time).

Please remember that visualisation of the probe can be changed by the

display block in defrosting function too, by using the parameter “dLo” (see

par. 4.4).

4.2 - TEMPERATURE CONTROL - The regulation of the instrument is

ON/OFF and acts on the output “OUT” depending on the measuring of probe,

of the Set Point “SP”, the intervention differential “HSEt” and the function

mode “Func”. Depending on the function mode programmed on the

parameter “Func” the differential is automatically considered by the regulator

with positive values for a Refrigeration control (“Func”=CooL) or with negative

values for a heating control (“Func”=HEAt). In the event of probe error, it is

possible to set the instrument so that that the output “OUT” continues to work

in cycles according to the times programmed in the parameter “tonE”

(activation time) and “toFE” (deactivation time). If an error occurs on the

probe the instrument activates the output for the time “tonE”, then deactivates

it for the time “toFE” and so on whilst the error remains. Programming “tonE” =

OFF lthe output in probe error condition will remain switched off. Programming

instead “tonE” to any value and “toFE” = OFF the output in probe error

condition will remain switched on. Remember that the temperature regulation

function can be conditioned by the “Compressor Protection” function described

below.

4.3 - COMPRESSOR PROTECTION FUNCTION AND DELAY AT POWER-

ON - The function “Compressor Protection” carried out by the machine aims to

avoid close start ups of the compressor controlled by the instrument in cooling

applications. This function foresees a time control on the switching on of the

“OUT” output associated with the temperature regulation request. The

protection consists of preventing the output being switched on during the time

set in the parameter “PtC” and counted depending on what has been

programmed in the parameter “PSC”, and therefore that any activation occurs

only after the “PtC” time has finished. If during the power on delay phase, the

regulator request should disappear, due to an inhibition caused by the

compressor protection function, the foreseen start up of the output is naturally

cancelled. Using the parameter "PSC", it is possible to set the type of

compressor protection and therefore from when the inhibition time “PtC” must

start. The parameter “PSC” can be set as:

= 1 : Power on delay

= 2 : Delay after power off

= 3 : Delay between power on phases.

The function is disabled by programming “PtC” = 0. During the power on delay

phases of the OUT output by inhibiting the function “Compressor Protection”

the led OUT flashes. It is also possible to prevent activation of the output after

the instrument is turned on, for the time set in the parameter “od”. The

function is disabled by “od” = OFF. During the power on delay phase, the

display shows the indication od, alternating with the normal programmed

visualisation.

4.4 - DEFROST CONTROL - The automatic control of defrost, that is by

stopping compressor, occours according to this parameters:

"dCt" : Defrost interval computation

- rt - based on real time (instrument on)

- ct - based only on compressor running time (output on)

"dint" : Interval between defrost cycles

"dEFE" : Lenght of defrost cycles

The instrument switch off the output for the time “dEFE” each “dint” time (of

real time functioning if “dCt” = rt, or of compressor running time if “dCt” = ct).

The occurring defrost cycle is signalized by the led DEF. Through par.

“dLo”,“Etdu” and “dALd” it’s possible to define the display behaviour during

defrost. The “dLo” parameter pemits the display visualization lock on the last

temperature reading (dLo = On) during all the defrost cycle until, at the end of

defrost, the temperature has not reached the value [SP + Etdu] or is ended the

time setted on par. "dALd". Or it permits the visualization of label "dEF" (“dLo”

= Lb) during the defrost cycle and, after the defrost, of label "PdEF" until, at

the end of defrost, the temperature has not reached the value [SP + Etdu] or is

ended the time setted on par. "dALd". The display will otherwise continue to

visualize the temperature measured by the probe during the defrost cycle

(“dLo”= OFF).

4.5 - MANUAL DEFROST - To start up a manual defrosting cycle, press the

key UP/DEFROST when it is not in programming mode and keep it pressed

for about 5 seconds after which, if the conditions are correct, the led DEF will

light up and the instrument will carry out a defrosting cycle.

4.6 - FUNCTIONING OF KEY “U” - The U key function can be defined by the

parameter “USrb” and can be configured for the following functions:

= OFF - The key U carries out no function.

= 1 - Pressing the key for at least 1 second, it is possible to switch the

instrument from the ON status to Stand-by status and vice versa.

4.7 - PARAMETERS CONFIGURATION BY “KEY01” - The instrument is

equipped with a connector that allows the transfer from and toward the

instrument of the functioning parameters through the device TECNOLOGIC

KEY01 with 5 poles connector.

For additional info, please have a look at the KEY01 instruction manual.

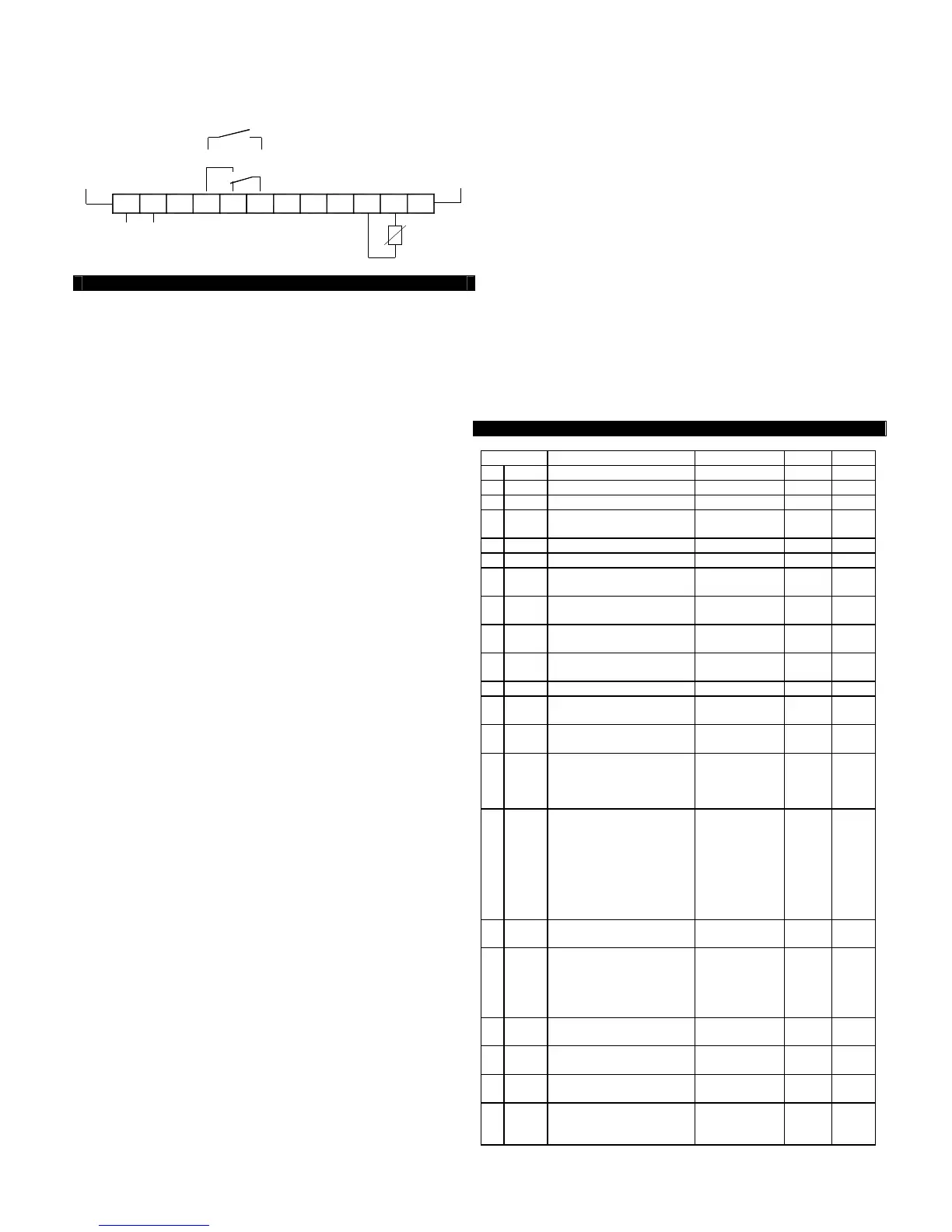

5 - PROGRAMMABLE PARAMETERS TABLE

Par. Description Range Def. Note

1

SPLL

Minimum Set Point -58.0 ÷ SPHL -50.0

2

SPHL

Loading...

Loading...