10

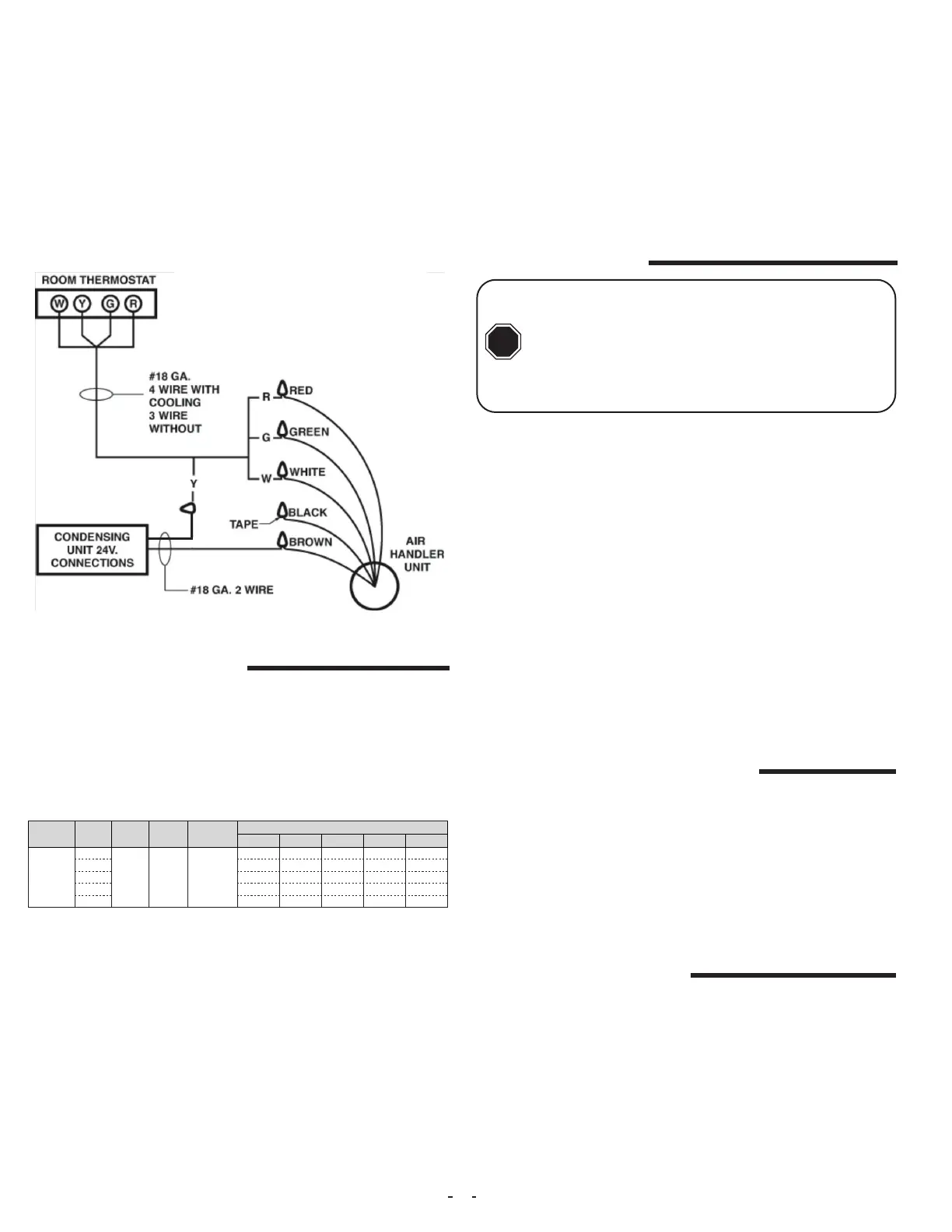

During cooling mode operation, the indoor blower G wire will ener-

gize a time delay relay inside the electric furnace. After a short time

delay period, the time delay relay contacts will close and apply power

to the blower motor. Fan delay periods are 7 seconds ON delay and

65 seconds OFF delay. (See Schematic)

The Y wire from the thermostat is not connected at the electric fur-

nace. This wire goes directly to the outdoor unit 24 volt wiring to turn

on the outdoor condensing unit when a call for cooling takes place.

The 24 volt common for the outdoor unit circuits is connected at the

electric furnace Brown wire.

The electric heater low voltage wiring W terminal is wired directly

from the thermostat to the electric furnace. The blower will delay a

heat call ON for a period of 5 seconds. The OFF delay period is 60

seconds.

Fig 5A-2.

Table 6-1.

Air volume needs to be set to the level recommended by the outdoor

unit equipment manufacturer. Most systems will require around 400

CFM of indoor air for every 1 ton of system cooling capacity. The air

volume must be set prior to attempting system charge.

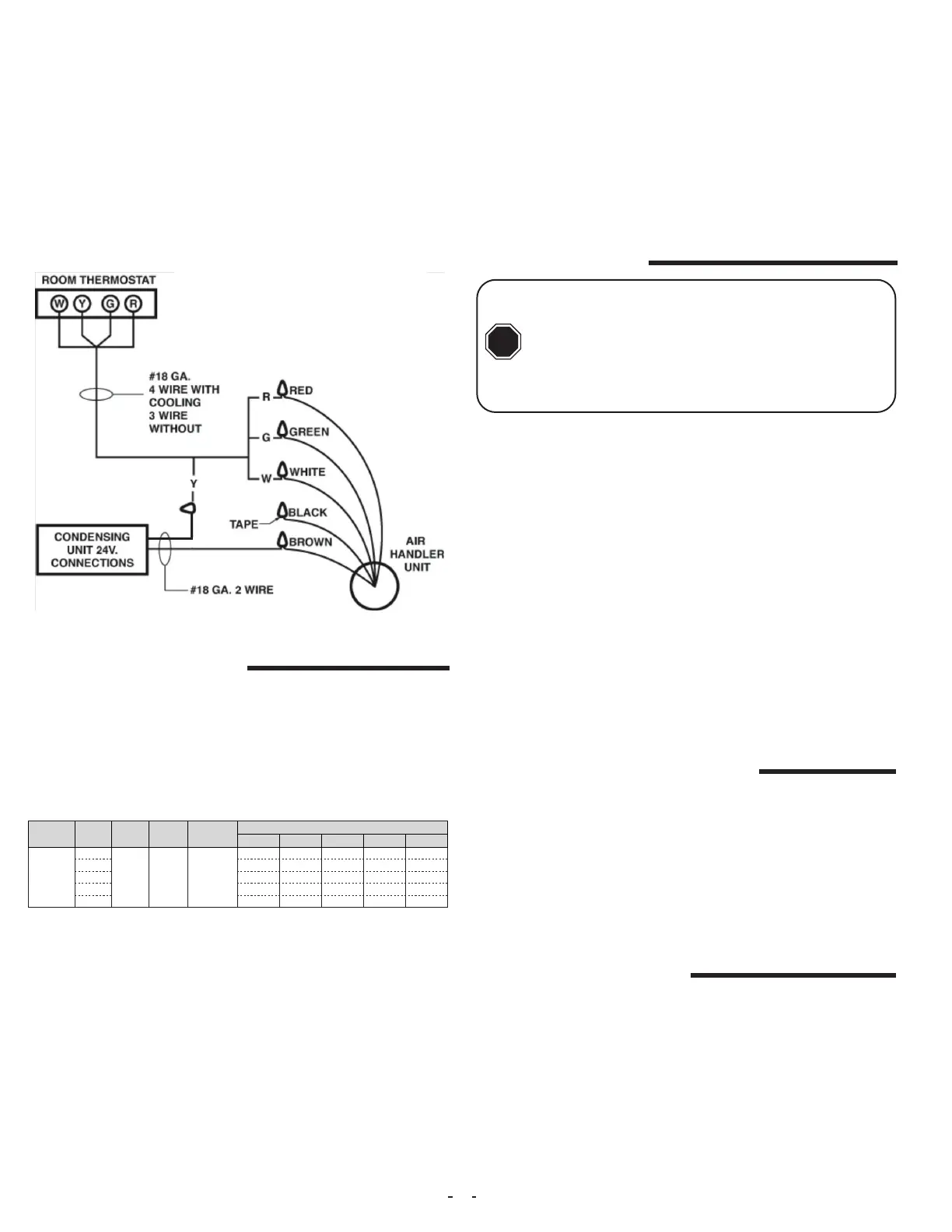

This electric furnace uses a 240V PSC motor. The air volume level

produced by the electric furnaces at varying external static pressure

levels is shown in Table 6-1.

6. Air Volume Adjustment

Use a Magnehelic Gauge with a 1” scale and two static pressure

tips to measure the static pressure during the air volume adjustment

procedure. The high port static pressure tip should be placed in the

supply duct near the outlet of the electric furnace. The low port static

pressure tip should be placed in the return air duct near the entrance

to the electric furnace. The factory provided air lter should be in

place inside of the electric furnace.

1. Select a starting speed tap from the CFM table.

2. Call for fan only operation at the thermostat.

3. Read the external static pressure level on the Magnehelic gauge.

4. Make speed tap selection changes to get the air volume as close

as possible to the required level.

5. If the static pressure is above .5” wc , excessive turbulence or duct

friction needs to be reduced. (Obstructions in the duct system can

also cause excessive static pressure.)

6. When proper air volume is established, move on to the charging

procedure.

MODEL

SPEED

TAP

MOTOR

HP

MOTOR

AMPS

MOTOR

VOLTAGE

CFM V. EXTERNAL STATIC*

0.10 0.20 0.30 0.40 0.50

AE(U/D)

T1

3/4 5.4 240

940 850 795 740 640

T2 1155 1070 1015 950 885

T3 1375 1305 1255 1180 1127

T4 1500 1430 1375 1315 1260

T5 1850 1800 1760 1710 1650

1. Bring airow up to the maximum CFM possible according to Table

6-1.

2. Evacuate refrigeration system to micron level required by outdoor

unit manufacturer.

3. Release system charge from outdoor unit and call for cooling.

4. Use outdoor unit equipment manufacturer specic charging charts

if available and make proper charge adjustment based upon outdoor

unit instructions.

5. If outdoor unit instructions and charts are not available, use Aspen

provided charts. Make certain indoor air temperature is near comfort

level setpoint 75F, prior to establishing superheat and subcooling

levels.

7. System Charging

An improperly charged system may cause degradation in sys-

tem performance and damage the compressor. After installation

of the coil, refer to the outdoor unit manufac-

turer for charging techniques and amount of

charge. If outdoor unit manufacturers charg-

ing instructions are unavailable; then refer to instructions below

to charge the system.

CAUTION

!

After all connections are made, start-up and checkout must be per-

formed before proper evaluation of the entire system can be made.

Make sure that heat anticipator is properly set as noted on thermo-

stat instructions. Load requirements can vary in each residence and

it may be necessary for the installer or homeowner to make slight ad-

justments to the heat anticipator setting for longer or shorter cycles.

It is recommended to change the setting no more than plus or minus

0.05 amps at a time. Greater changes can cause the unit to rapid

cycle or remain on excessively. Measure anticipator circuit current

with electric heaters energized and set anticipator to proper level.

8. Adjustment Of Heat Anticipator

9. Final System Checkout

1. Make certain all cabinet openings are properly sealed and any

grommets moved during installation are moved into proper place.

2. With cooling system operating, check for condensate leakage.

3. Perform leak detection inspection of refrigerant circuit and con-

necting piping.

4. Secure all cabinet doors

Loading...

Loading...