IB-2003 Series 40 Transfl ite - Stationary Conveyor

57

Appendix A: Disc Wheel Installation

Disc Wheel Installation

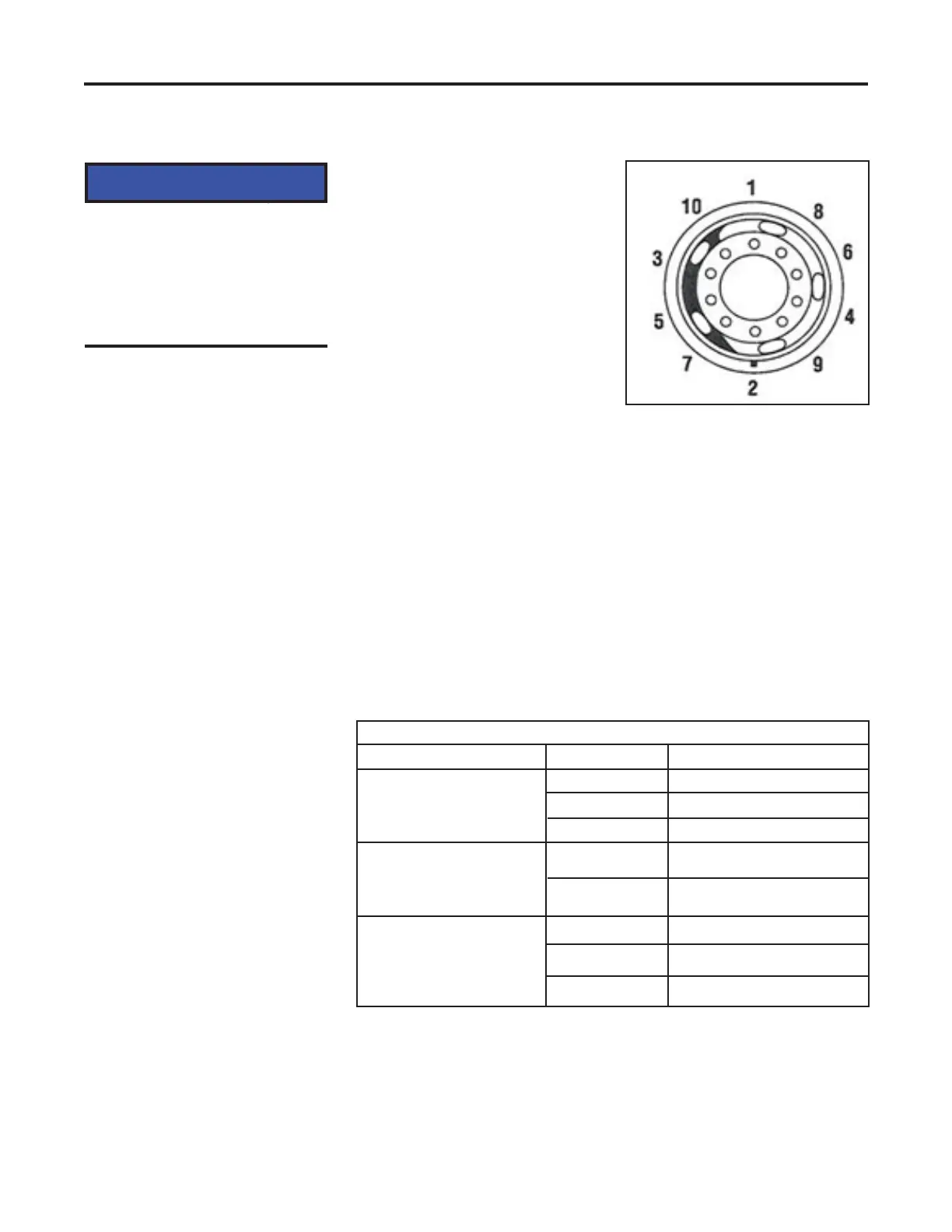

Torque Chart - Wheel Installation

Mounting Type Nut Thread Torque Level

Hub-piloted with

fl ange nut

Stud-piloted, double

cap nut-standard type

(7/8” ball seat radius)

Stud-piloted, double

cap nut-heavy duty

type

(7/8” ball seat radius)

11/16” - 16

M20 x 1.5

M22 x 1.5

3/4” - 16

1-1/8” - 16

15/16” - 12

1-1/8” - 16

1 5/16” - 12

300-400 ft.lbs. (oiled)

280-330 ft.lbs. (oiled)

450-500 ft.lbs. (oiled)

450-500 ft.lbs. (dry)

450-500 ft.lbs. (dry)

750-900 ft.lbs. (dry)

750-900 ft.lbs. (dry)

750-900 ft.lbs. (dry)

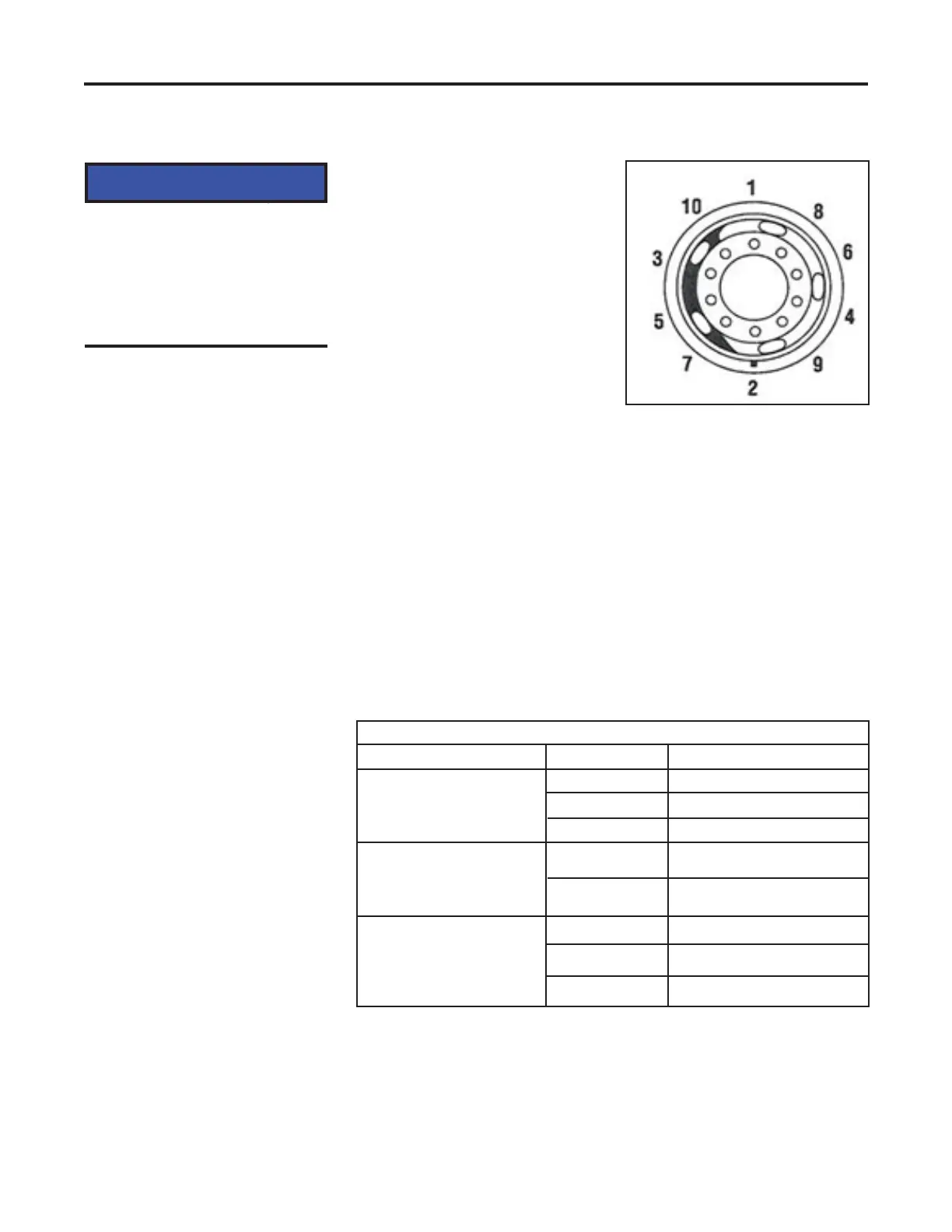

2. Install nuts using proper

installation sequence

shown to the right. Snug

nuts to 50 ft.lbs. Do not

tighten fully until all nuts

have been seated. Then

torque to specifi cation as

shown on the torque chart

below using the same

sequence used for

installation.

3. After wheel assembly has

been installed, recheck the

torque level after 50-100

miles of operation and

retighten if necessary to

the recommended torque

using the proper sequence

as shown to the right.

a. To check and retorque

an inner cap nut, it is

necessary to loosen

NOTICE

1. Hub-piloted wheels

For nuts used on hub

piloted wheels, apply two

drops of oil to a point

between the nuts and

fl anges and two drops to

the last 2 or 3 threads at

the end of each stud.

Lightly lubricate the pilots

on the hub to ease wheel

installation and removal.

Do not get lubricant on

the mounting face of the

drum or wheel.

Stud-piloted wheels

Do not use lubrication on

nuts used on stud-piloted

wheels. Never lubricate

wheel or nut ball seats or

mounting faces. If

lubrication is used, consult

the wheel manufacturer

for torque

recommendations.

Never mix hub-piloted and

stud-piloted wheels, hubs,

and nuts. The result could

be loss of torque, a cracked

wheel or possible wheel

loss.

the outer cap nut fi rst

and then tighten the

inner cap nut.

Retighten outer cap

nuts to the proper

torque.

b. It is recommended that

a torque check be

made when checking

the tire pressure.

Information courtesy of The Maintenance Council of The American Trucking Association). For complete wheel service

guidelines see TMC RP-222, “User’s Guide to Wheels and Rims”.

Loading...

Loading...