710

KDS

Astec Mobile Screens Setup 16 KDS 710

D

esigned for construction and recycling contractors, the KDS Series of mobile screening plants

are easy to operate and highly reliable in processing recycled materials, crushed stone,

demolition waste, topsoil and more. These robust machines offer heavy-duty plate steel and

AR liners at high impact areas, giving a much longer life while processing demanding loads. Capable

of processing on site and in tight construction areas, the KDS Series reduces hauling costs and

minimizes material purchase requirements.

710: Direct feed double deck screen; 10’ x 6’-8

1/2

” with heavy duty bolted design. Direct feed area

constructed of heavy 1/4” plate steel with 1/4” AR liners and provides 12’ top feed opening for 3-5 yard

loader material feed. Standard material separations range from 4” to 1/2”.

SCREEN

710: 80 continuous HP @ 2200 RPM, John Deere water-cooled diesel engine equipped with all in-

strumentation; electric start, Murphy shut down system and ground mounted controls: All systems

are hydraulically operated and include o-ring face seal settings; Four (4) hydraulic pumps: Two (2) for

track operation, one (1) to operate screen and another for auxiliary power; Auxiliary power includes

quick couplers to power optional nes conveyor as well as quick couplers to power a hydraulic stack-

ing conveyor.

POWER SYSTEM

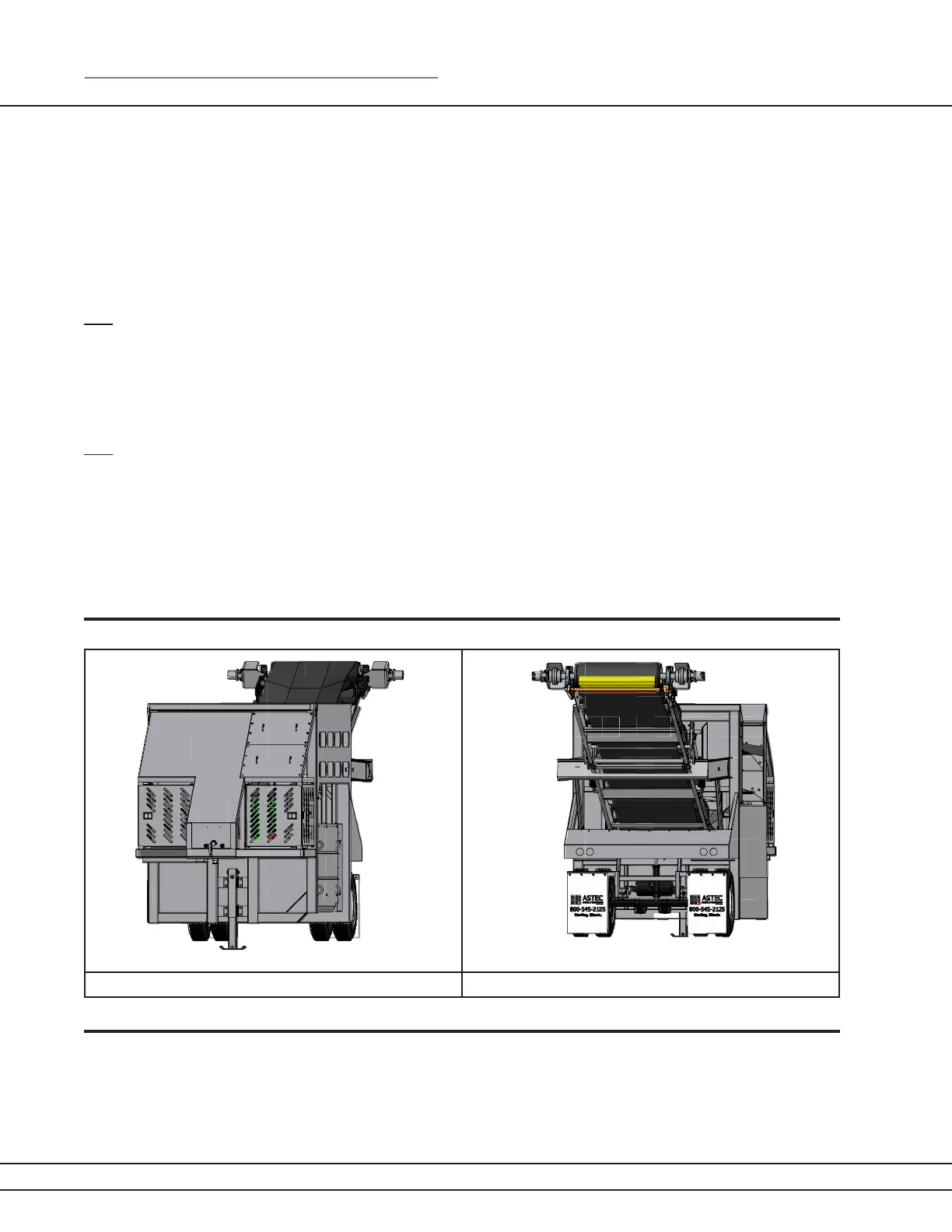

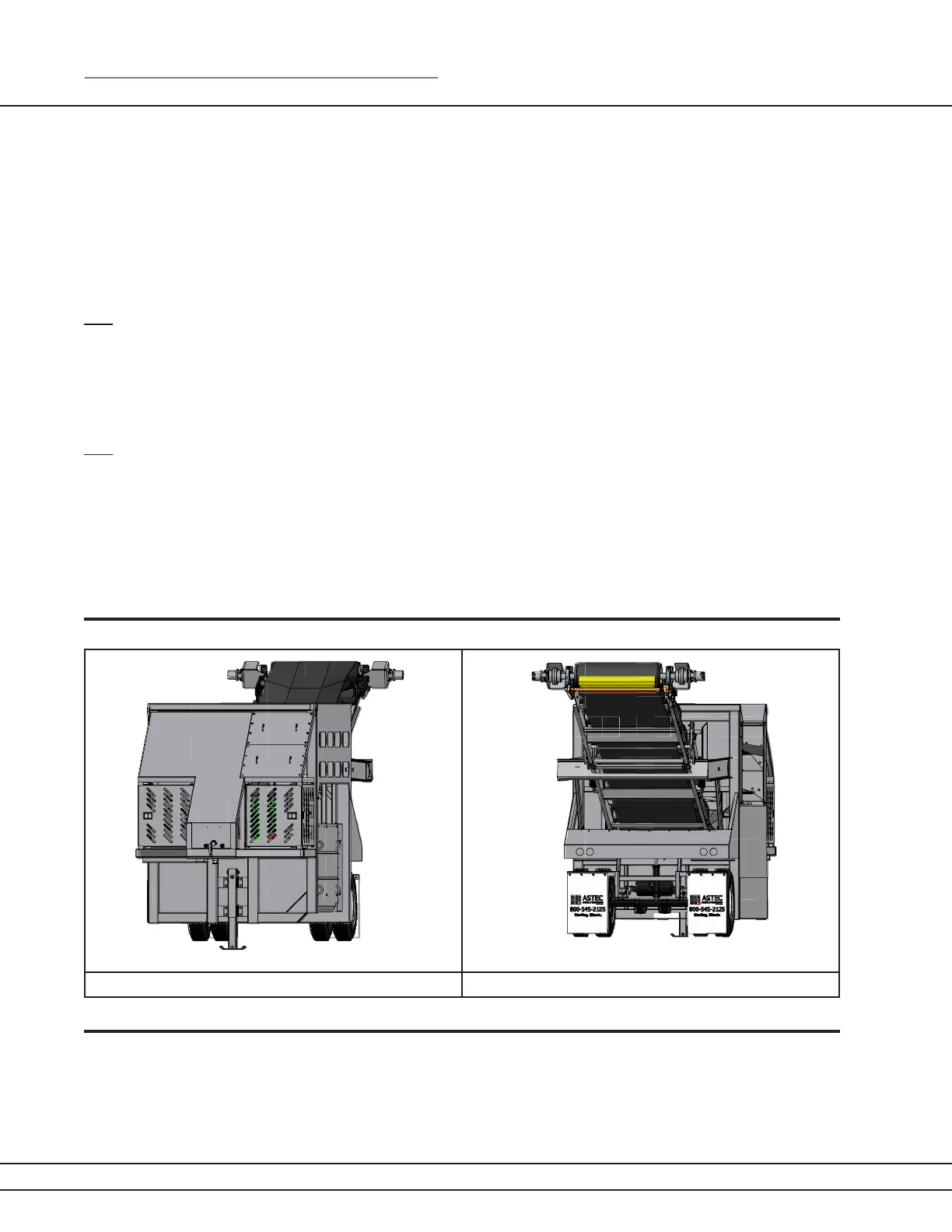

Front View Rear View

Loading...

Loading...