lll. OPERATION GUIDE:

lV. MAINTENANCE:

1. The nut riveting adapter is

lubricated before shipping.

Recommended: cleaning

the components of plunger

tube, and using lubricant

grease to re-lubricate its

parts on a yearly basis

or earlier.

2. Threaded mandrel

replacement:

Life span of threaded mandrel varies with usage

frequency and the uses of different rivet nut sizes/types.

Recommended: replacing the threaded mandrel with

new spare and its nosepiece before worn-out.

WARNING: The objects to be riveted MUST BE

SECURELY FIXED BEFORE riveting in order to avoid

possible injury. Unsecured objects may rotate with the

driving tool if not secured.

IMPORTANT: Ensure the threads on mandrels are clean

and the loaded rivet nut has full thread engagement with

threaded mandrel during riveting. It is strongly

recommended to clean and lubricate (ex. silicone spray)

the threads on mandrels before and after use.

CRITICAL: Before using the tool on your intended work

piece, it is REQUIRED that you test the tool with a rivet nut

on a test piece to determine the adequate torque needed

for your rivet nut size, rivet nut material, and sheet metal

thickness and material.

• Ensure drill is in "driver" mode and not drill mode.

Different drills will require different torque limiting settings

for the same material.

• On the test piece, set your drill to a low clutch setting and

work up to higher settings until the torque level is enough

to fully set the rivet nut but not over set - WARNING: Over

setting rivet nuts may permanently damage the mandrel or

tool.

• Once the torque level is determined, test again on a new

hole at your intended setting to confirm. The knurled part

of the rivet nut should look mushroomed and starting to

become flat on the other side of the work piece and should

not rotate when you install a bolt.

ADN14

MODEL: PRODUCT TYPE:

Page 3

RIVET NUT DRILL ADAPTER KIT

2.4 Ensure the rivet nut has adequate thread

engaged

and that there is no cross threading. Check

and confirm the objects to be riveted are SECURE.

2.5 Some small amount of clearance between nose

piece and the flange of rivet nut may be beneficial to

operation, but keep adequate thread engagement on

the nut.

2.6 Refer to Section III. for determining the proper

drill torque settings. (REQUIRED).

2.7 Put the rivet nut now threaded onto the tool's

mandrel fully into the proper size hole (see Sizing Chart

on page 2).

2.8 Align the adapter with the hole angle as best

you can. While gripping the adapter firmly with one hand

(wear work gloves), operate the drill in the FWD

direction until you feel or hear the drill's torque clutch

catching.

The adapter should not rotate while the drill

works. Release your grip on the adapter and reverse

the drill out of the rivet nut. Depending on the material,

you may need to manually help the adapter thread out

of the rivet nut with your off hand.

Tip 1: If the torque setting of your drill is too high,

not on, or on a drill setting, you WILL damage the

rivet nut, workpiece, mandrel or tool. Monitor

threads for burrs and lubricate when needed.

Tip 2: Make a note of the torque setting matching

your application for future use.

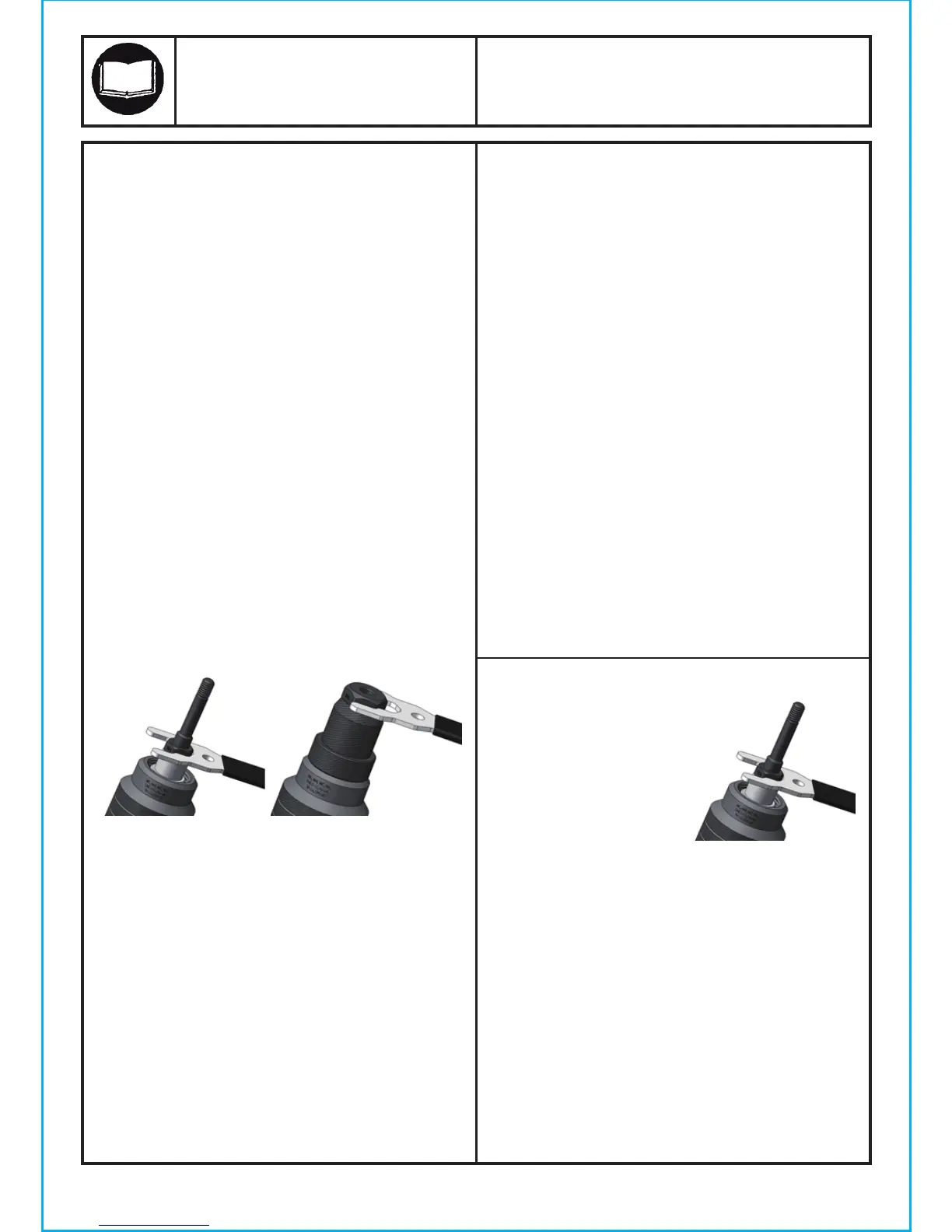

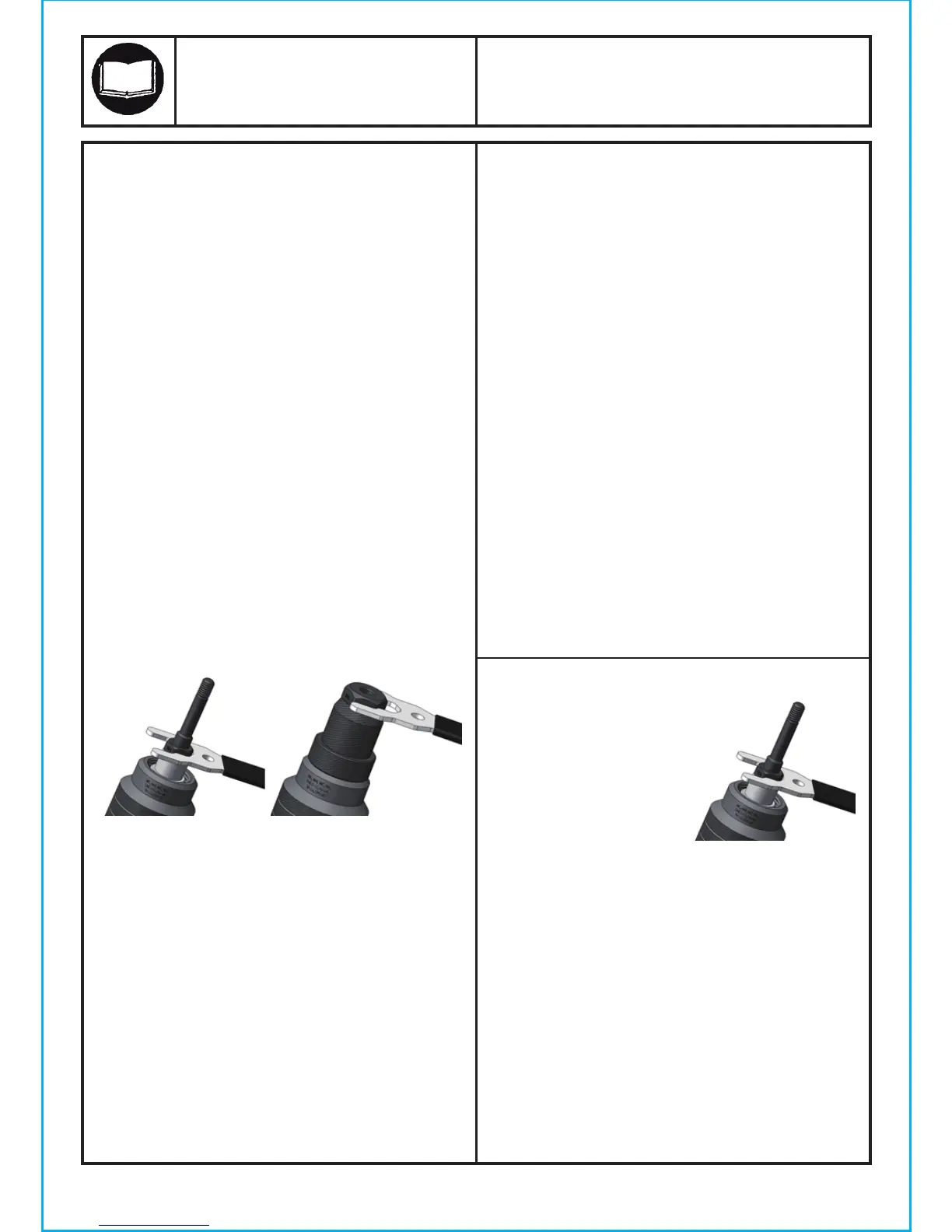

1. Tool Installation:

Install a new mandrel and nosepiece to match your

intended rivet nut thread size. Use the included wrench

to install the new

mandrel into the #2 Plunger Tube.

Ensure that the mandrel and other components are

tightly fixed in position. After installing the front bushing

cover and lock bushing, lightly tighten the new

nosepiece onto the end of the tool. Install the hex shank

drive end of the tool into your drill and affix into its chuck.

2. Riveting:

2.1 While holding the adapter with your hand, operate

the drill in the REV direction until you hear the adapter

start to click. This means it has fully exposed the

mandrel.

2.2 Switch the drill to the FWD setting.

2.3 Manually thread the selected rivet nut onto threaded

mandrel; or hold the rivet nut in one hand and use

another hand to pull the drill trigger slightly to have the

nut threaded on by the tool.

Loading...

Loading...