U0594061-DPage 18 / 82 CORFIRST / CORSUN 2 / CORFLOW

EN

4. FITTING MAGNESIUM PROTECTION ON THE UPPER BASE

Refer to the specic Anode manual for the installation.

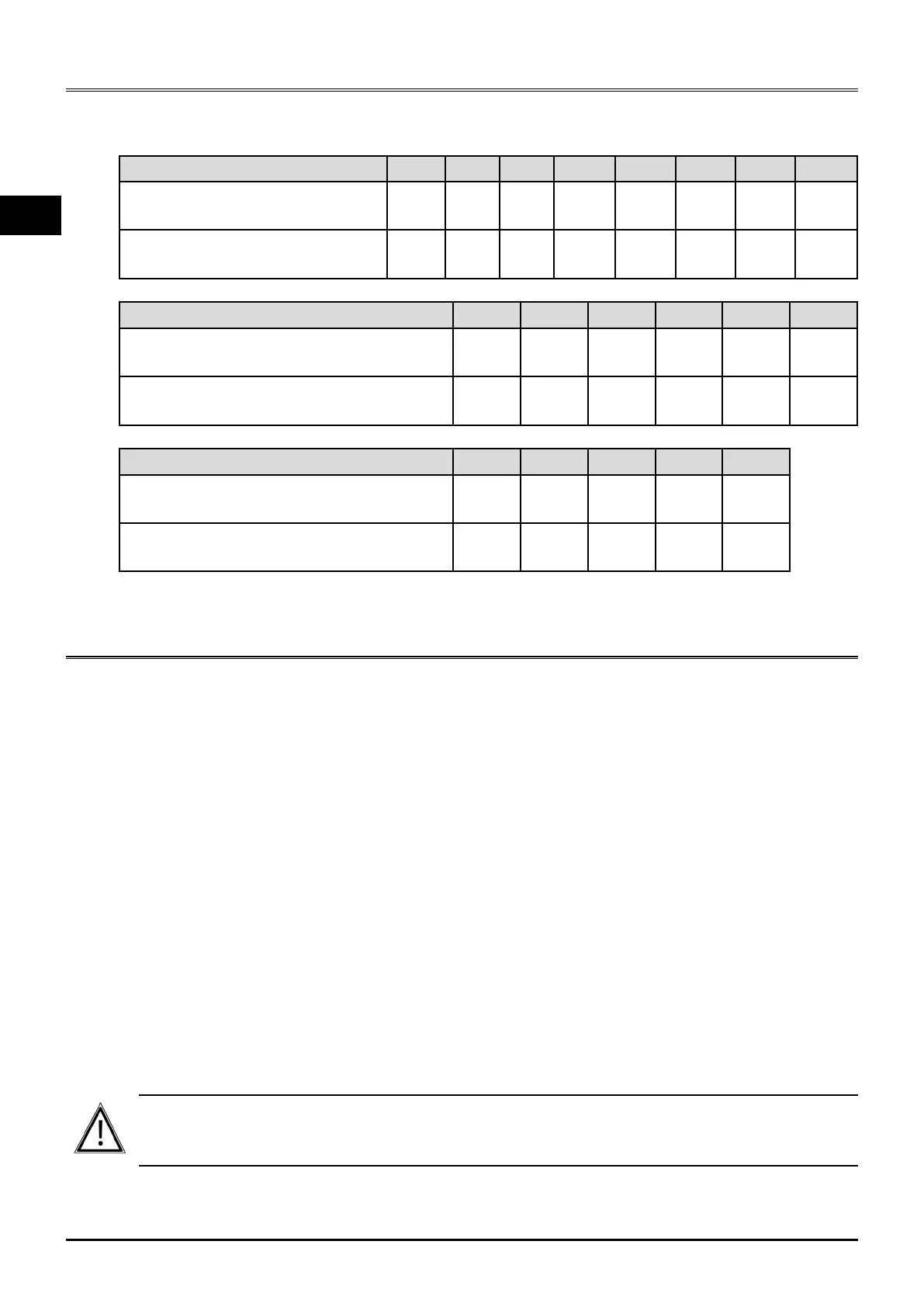

CORFIRST 500L 750L 900L

1000L 1500L 2000L 2500L 3000L

Dimension of rough anode on

upper base

400 500 800 800 1000 650 650 800

Minimum tting dimension +

riser blocks 2

2250 2385 2965 3210 3165 2730 3090 3665

CORSUN 2 500L 750L 900L 1000L 1500L 2000L

Dimension of rough anode on upper

base

600 500 400 400 650 650

Minimum tting dimension + riser

blocks 2

2450 2385 2565 2810 2815 2730

CORFLOW 500L 750L 900L 1000L 1500L

Dimension of rough anode on upper

base

500 800 1000 1000 1000

Minimum tting dimension + riser

blocks 2

2350 2685 3165 3410 3165

5. HYDRAULIC CONNECTION

Before proceeding with the hydraulic connection, the supply pipes must be thoroughly

cleaned to avoid introducing metal or other particles into the tank.

If metal pipes are used, the connection to the hot water outlet must use a dielectric pipe

joint or cast-iron sleeve to prevent galvanic corrosion (iron-copper). Brass connections

are prohibited here. A certied safety unit or non-return ap and safety valve assembly is

obligatory.

If the network supply pressure is ≥ 5 bar, a pressure reducer must be tted to the distribution

outlet. A pressure of 3 to 4 bar is recommended. Check when hot that the pressure does not

exceed 6 bar..

Fit a bleed outlet to the tank´s top connection (DHW outlet).

To avoid clogging the installation´s components (heat exchangers, safety valve, safety unit)

with sludge, a lter must be tted to the domestic cold water supply outlet feeding the tank.

The domestic hot water in the tank can reach a high temperature. It is thus essential to t a

thermostatic mixing valve before water is distributed to the taps. The temperature setting at

the taps should comply with the regulations in force.

If COMPOSITE MATERIAL pipes (PER, PVC etc.) are used a temperature limiter must

be tted to the tank output and adjusted according to the performance of the material

used.

Loading...

Loading...