LUM12 HRX/HRX-RE EN Service

© Atlas Copco Industrial Technique AB - 9836 9388 01

13

For Maximum Performance

At tough working conditions – soft joints and max. setting – lubrication of the air is recommended.

With extreme dry air the service life of vanes and machine performance might be reduced. A daily supply

of 0.1 – 0.2 ml oil into the machine inlet will improve the machine performance. Alternatively consider an

automatic lubricator device, Atlas Copco oil fog lubricator DIM, or single point lubricator DOS, which will

improve the machine performance.

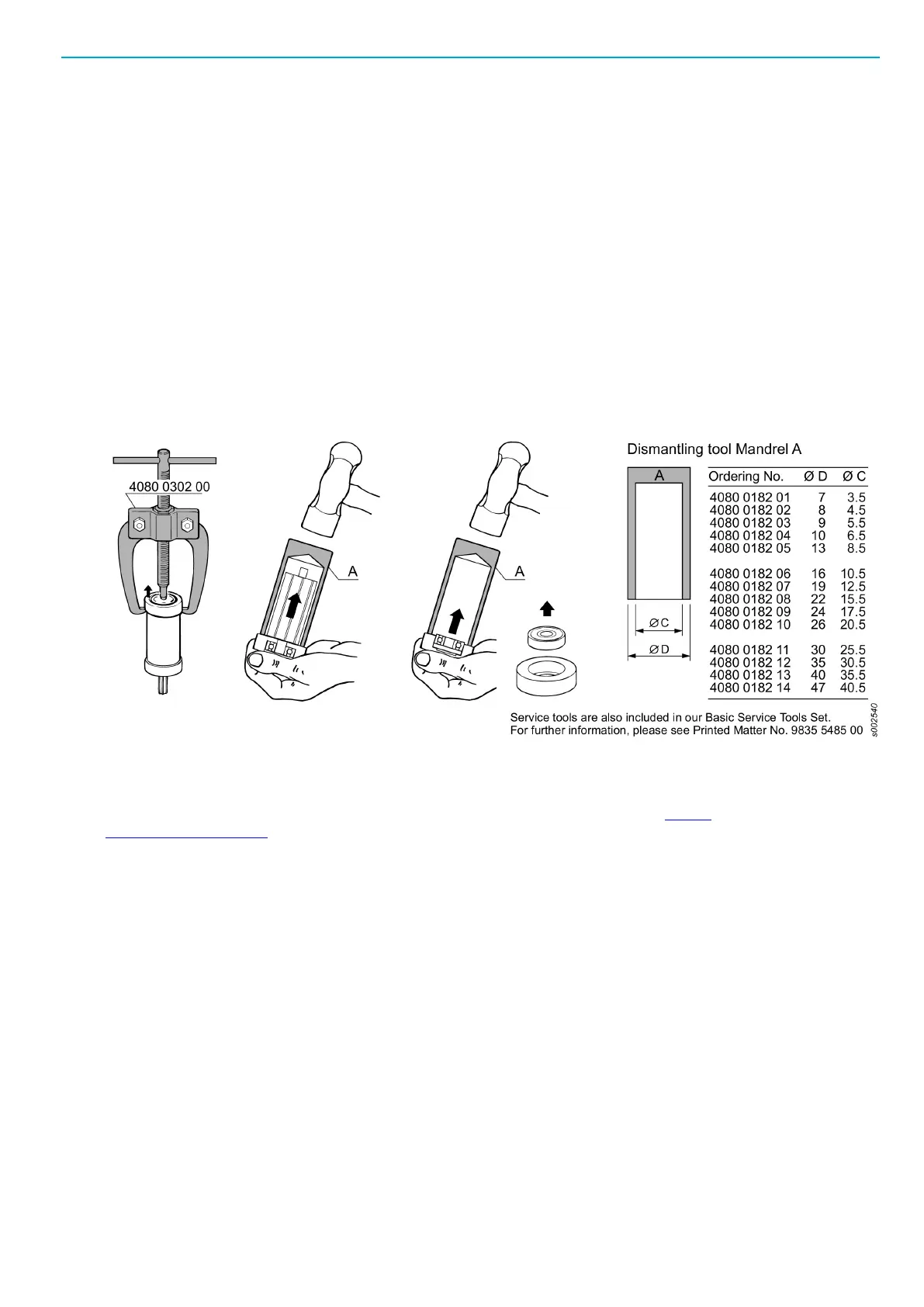

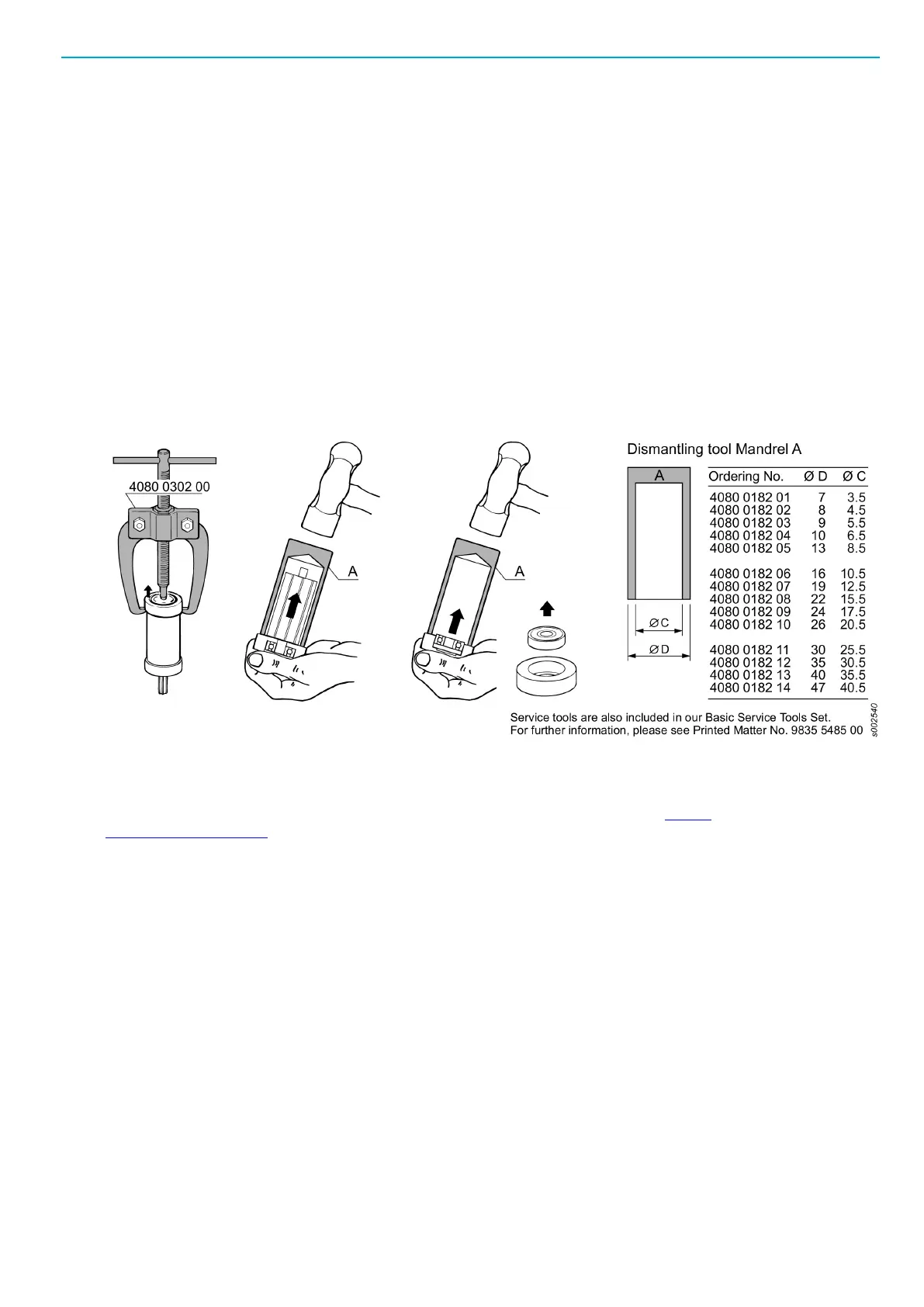

Dismantling/Assembling Instructions

Disassembling/Assembling

It is important that the machines threaded connections are tightened properly; i.e. in accordance with the

specifications on the exploded views.

Dismantling of Motor

Tightening of Threaded Connections

The tightening torque indicated in the exploded views (see Spare parts section in https://

servaid.atlascopco.com) will give the right clamping force and prevent parts from loosening. It is important

not to exceed the clamping force, these parts must be able to open up without being damaged at service.

After some time of operation and in special circumstances, depending on application and usage, the parts

may however loosen somewhat. The tightening torque can then be increased by 10-20% and some type

of low or medium thread locking fluid can be applied.

Loading...

Loading...