LUM12 PR EN Safety and operating instructions

© Atlas Copco Industrial Technique AB - 9836 927100 00

5

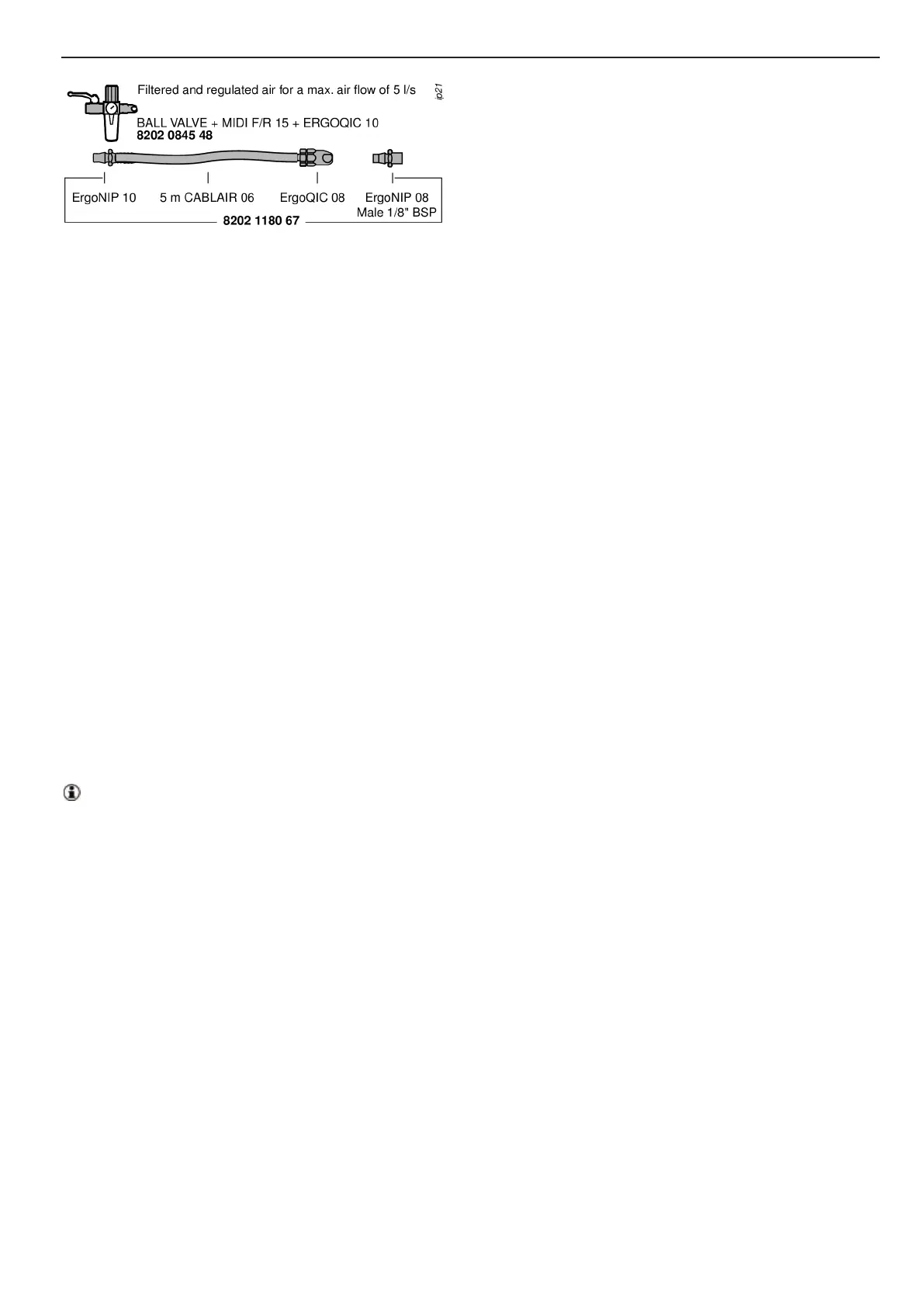

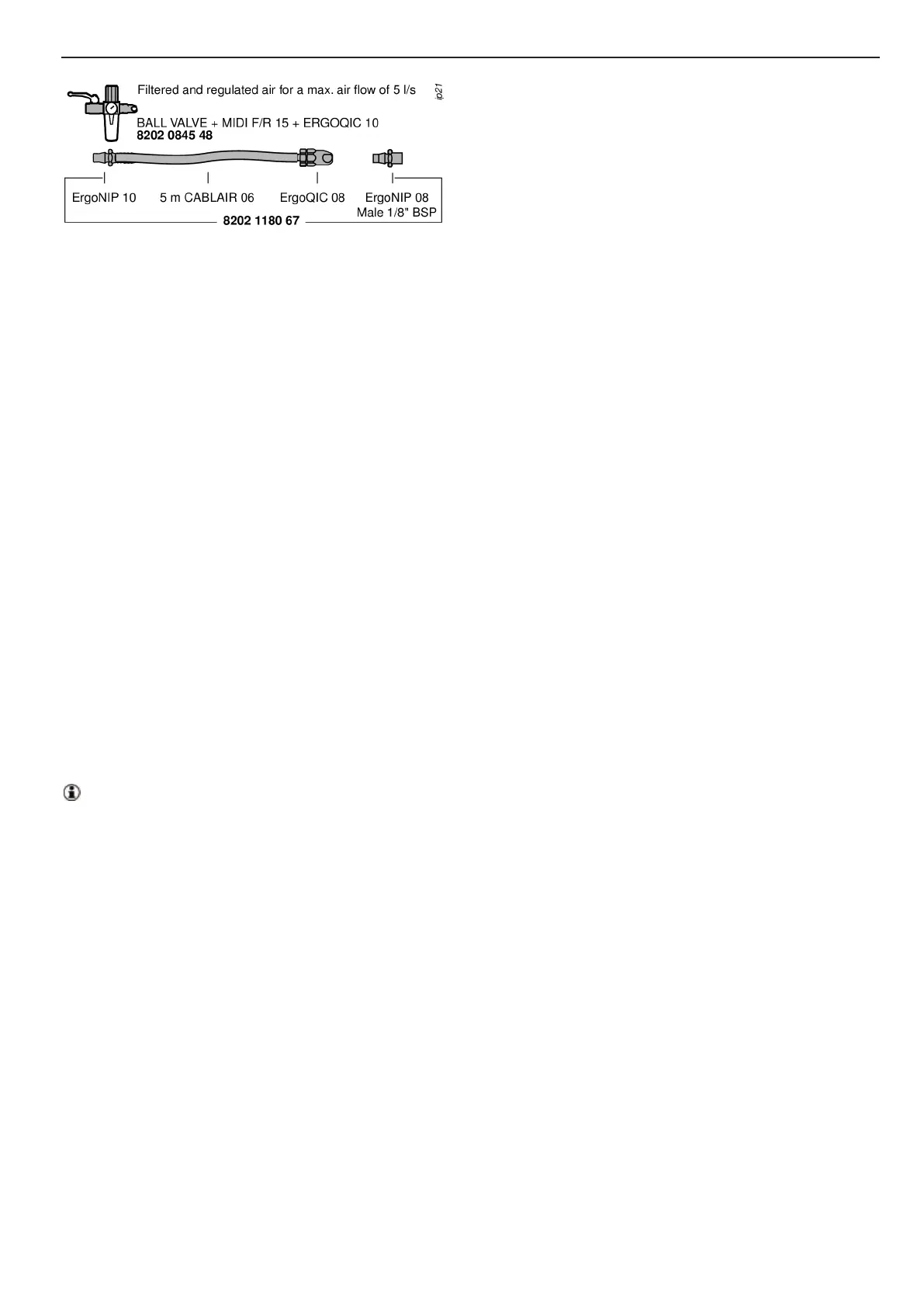

For more information please read, Atlas Copco Industrial Power Tools cata-

logue Ordering No. 9837 3000 01.

Handling

Operating instructions

See figure in Service instructions

Tightening torque

For accurate operation and safety, the tightening torque of the screwdriver must

be adjuisted correctly in relation to the screw joint. Check the torque specifica-

tion for the actual joint.

The tightening torque is adjusted by altering the tension of the clutch spring.

Turn the protection ring until the hole in the clutch housing is free. Then turn

the out going spindle until you can see the keyhole in the adjustment washer.

Turn the adjustment key clockwise to decrease and anticlockwise to increase

the torque. After the adjustment, turn the protective ring back again.

Verification of tightening torque

Atlas Copco Torque Analyser, ACTA 3000, plus an appropriately-sized in-line

transducer, IRTT together with the available test joints are recommended equip-

ment.

Torque range of the clutch springs :

Each clutch spring gives a certain torque range. Don’t adjust the torque

over the maximum recommendation as that might result in improper func-

tion and faster wear of the clutch.

The torque range of each spring is easily identified by it’s colour.

Maintenance

For maximum performance

At tough working conditions – soft joints and max. setting – lubrication of the

air is recommended.

With extreme dry air the service life of vanes and machine performance might

be reduced. A daily supply of 0.1 – 0.2 ml oil into the machine inlet will im-

prove the machine performance. Alternatively consider an automatic lubricator

device, Atlas Copco oil fog lubricator DIM, or single point lubricator DOS,

which will improve the machine performance.

Loading...

Loading...