AUSTIN-HKALEY SPRITE GENERAL MAINTENANCE

To adjust the contact breaker points, turn the engine with the

starting handle until the contacts are fully open. Slacken the

fixed contact plate securing screw '1'. insert a screw-driver in the

slot '2' and move the plate until the gap gauge is a sliding fit

between the contacts

(.014 to .016 in. or .36 to .41 mm.) and

then fully tighten the securing screw. Finally recheck the gap and

replace the rotor arm. B efore replacing the distributor cap

wipe the inside and outside with a soft dry cloth, paying particular

attention to the space between the terminals. Ascertain that the

small carbon brush on the inside of the cap works freely in its

holder and that the terminals are secure.

Coi/t The L.A.12 type Lucas ignition coil requires no attention

beyond checking that the terminal connections are tight and that

the exterior is kept clean, particularly between the terminals.

H.T. Cables: The high tension cables must be c arefully

examined and any which have the insulation cracked, perished or

damaged in any way must be replaced.

Sparking Plugs: The sparking plugs fitted to the Austin-Healey

Sprite are of the Champion N.5 Long Reach type, and as they

are of great importance to satisfactory engine performance, every

care should be taken to fit only the recommended type when

replacements become necessary.

Every 5,000 miles (8,000 km.), remove the plugs and clean off

all carbon deposit from the electrodes and plug threads with a

stiff brush dipped in paraffin.

Alternatively the plugs may be taken to the local Austin dealer

for cleaning and testing on a special 'Air Blast' service unit.

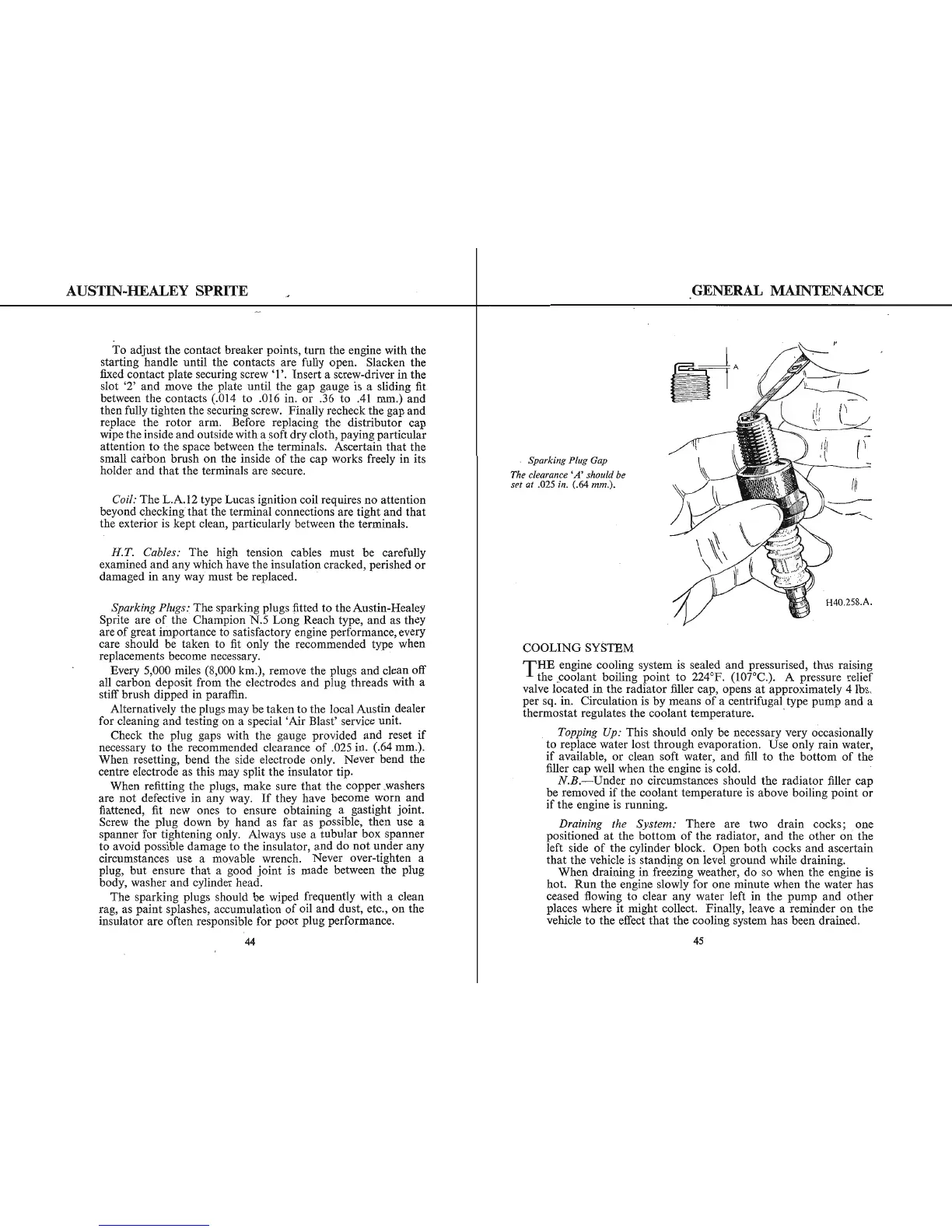

Check the plug gaps with the gauge provided and reset if

necessary to the recommended clearance of .025 in. (.64 mm.).

When resetting, bend the side electrode only. Never bend the

centre electrode as this may split the insulator tip.

When refitting the plugs, make sure that the copper washers

are not defective in any way. I f they have become worn and

flattened, fit new ones to ensure obtaining a gastight joint.

Screw the plug down by hand as far as possible, then use a

spanner for tightening only. Always use a tubular box spanner

to avoid possible damage to the insulator, and do not under any

circumstances use a movable wrench. Never over-tighten a

plug, but ensure that a good joint is made between the plug

body, washer and cylinder head.

The sparking plugs should be wiped frequently with a clean

rag, as paint splashes, accumulation of oil and dust, etc., on the

insulator are often responsible for poor plug performance.

T .

— Sparking Plug Gap

The clearance 'A' should be

set at .025 ln. (.64 mm.).

COOLING SYSTEM

HE engine cooling system is sealed and pressurised, thus raising

the coolant boiling point to 224'F. (107'C,). A pressure relief

valve located in the radiator filler cap, opens at approximately 4 lbs.

per sq. in. Circulation is by means of a centrifugal type pump and a

thermostat regulates the coolant temperature.

H40.258.A.

Topping Upt This should only be necessary very occasionally

to replace water lost through evaporation. Use only rain water,

if available, or clean soft water, and fill to the bottom of the

filler cap well when the engine is cold.

¹B.— Under no circumstances should the radiator filler cap

be removed if the coolant temperature is above boiling point or

if the engine is running.

Draining the System: There are two drain cocks; one

positioned at the bottom of the radiator, and the other on the

left side of the cylinder block. Open both cocks and ascertain

that the vehicle is standing on level ground while draining.

When draining in freezing weather, do so when the engine is

hot. Run the engine slowly for one minute when the water has

ceased flowing to clear any water left in the pump and other

places where it might collect. Finally, leave a reminder on the

vehicle to the effect that the cooling system has been drained.

45

Loading...

Loading...