PUMP HEAD INSTALLATION

The pump head is connected to driver unit by two m4 screws.

Insert the two screws into the mounting holes, connect the pump head

with the driver unit end to end, then tighten the screws.

To connect two or more pump heads, longer screws are needed.

PROMPT:

Try your best to tighten the two screws in the same degree. Do not

over-tighten the screws to prevent the support block from deforming

and buzz.

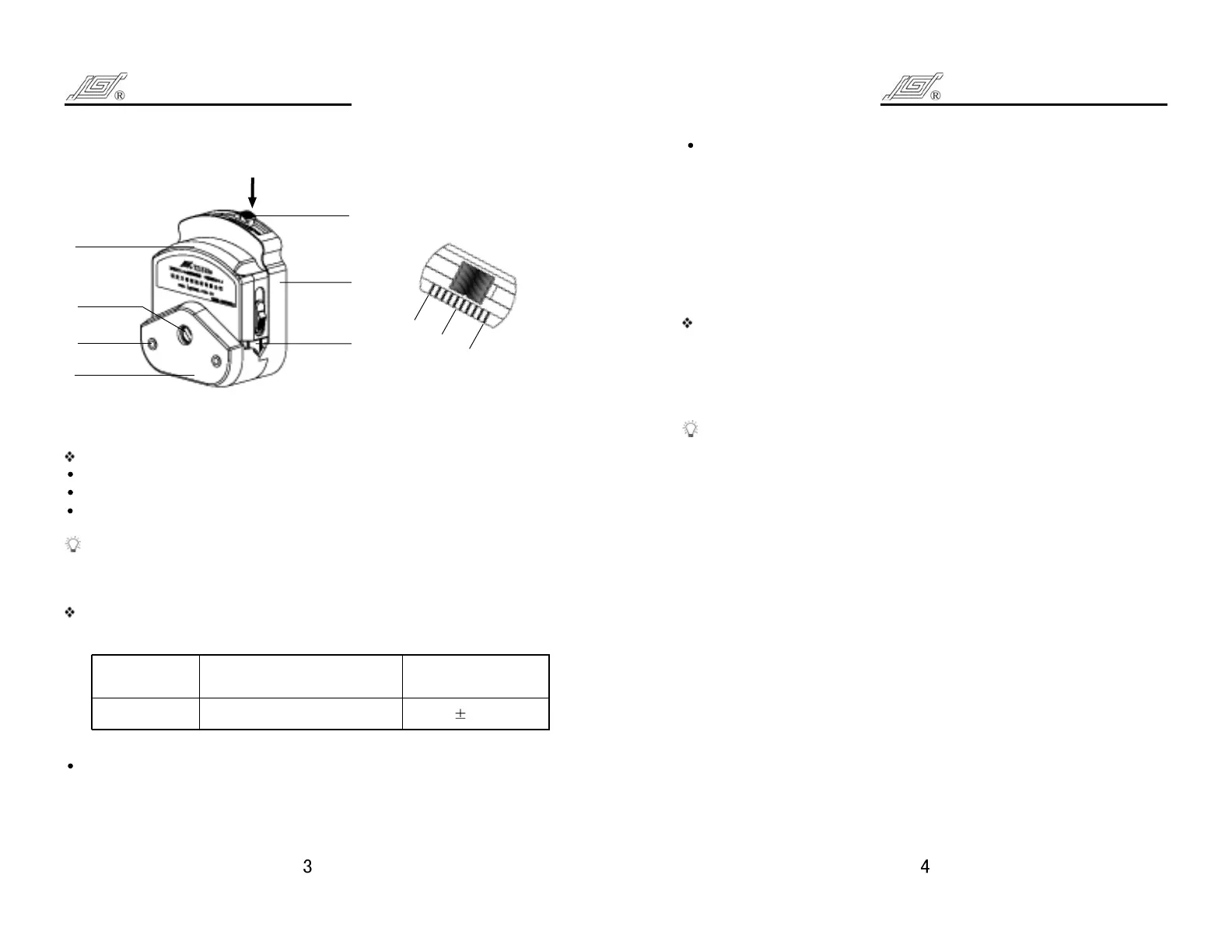

If the wall thickness of tubing is not standard, you can adjust the

occlusion as follows: first load the tubing, and push the lever to the left

end to make the occlusion maximum. Place the inlet of the tubing into

water and blow from the outlet, there are blebs. Then push the lever

to the right till there are exactly no blebs.

If there are still blebs after push the lever to the right end, it suggests

that the wall thickness of the tubing is too thin and beyond the appli-

cable range.

LongerPump

TM

YZ Series

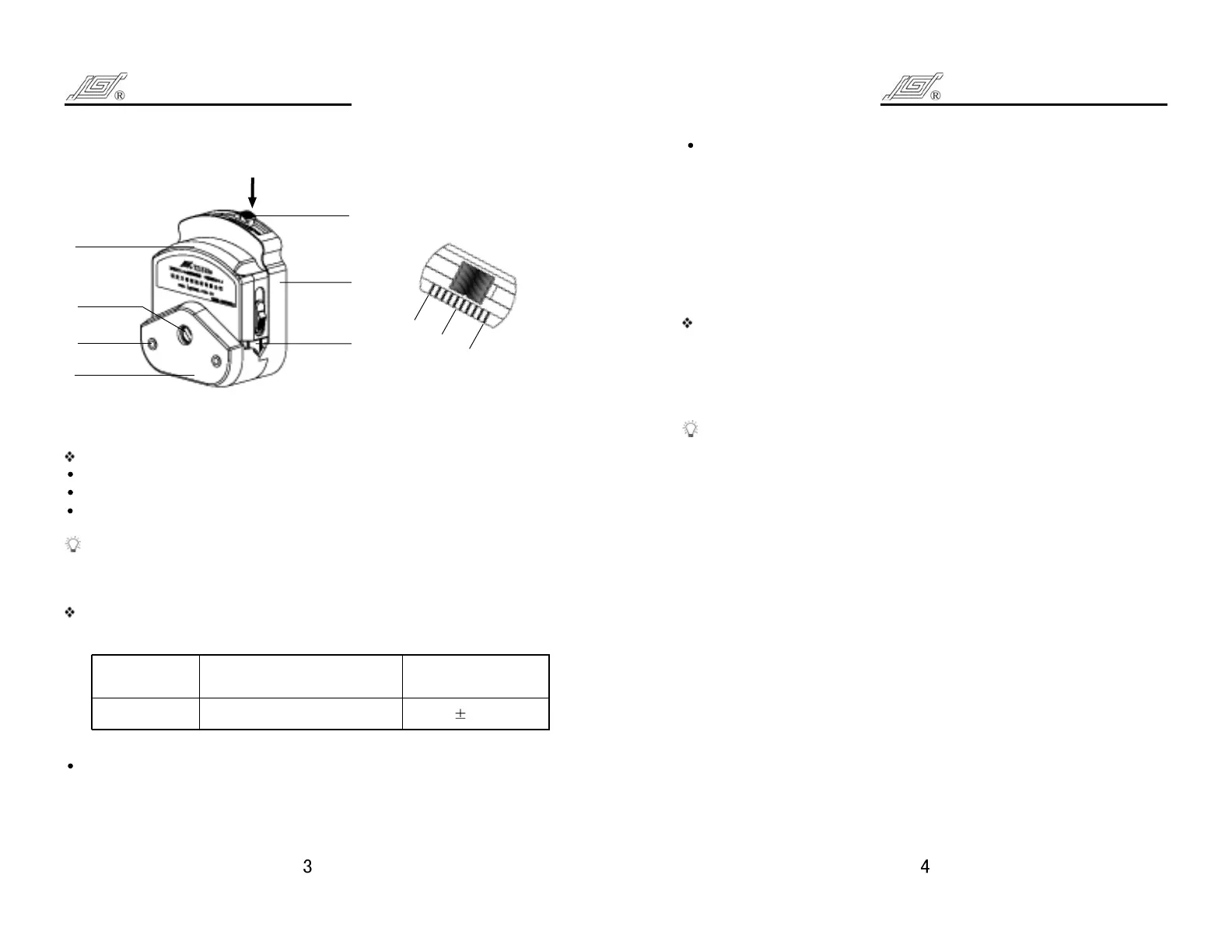

PUMP HEAD OPERATING

Press down lever and push back to left to open pump head.

Push tubing clamps at arrowhead direction and load tubing.

Press down lever and push back to right to close pump head.

ATTENTION

The tubing clamp on both sides of the compression block can fit differ-

ent sizes of tubing automatically. Don’t need to adjust.

PUMP HEAD OCCLUSION ADJUSTMENT(see K view)

YZ1515w pump head direction for use

K VIEW

A

B

k

Mounting

Holes

Lever

Compression

Block

Rotor

Base

Support

Block

Tubing

Clamp

YZ1515w

PUMP HEAD APPLICABLE TUBING

TUBING WALL

THICKNESS

YZ1515W

13

#

,14

#

,16

#

,25

#

,17

#

,18

#

1.6 0.3(mm)

For standard wall thickness tubing, the lever should be in the middle of

the index scale.

LongerPump

TM

YZ Series

Loading...

Loading...