Proper blade maintenance is important in order for the cutter to work properly, to always

obtain a precision cut and to lower HP requirements thus keeping costs down.

Blades must be kept sharp, at their original length and with corners intact. A blade must

be replaced if, due to wear or damage, its original shape has been distorted.

Blade sharpening is extremely important in order to get the best cutting results.

Removing or installing blades

Never rely on the tractor lift system to support the machine while working underneath.

Install blocks or stands under the cutter deck to prevent it from falling.

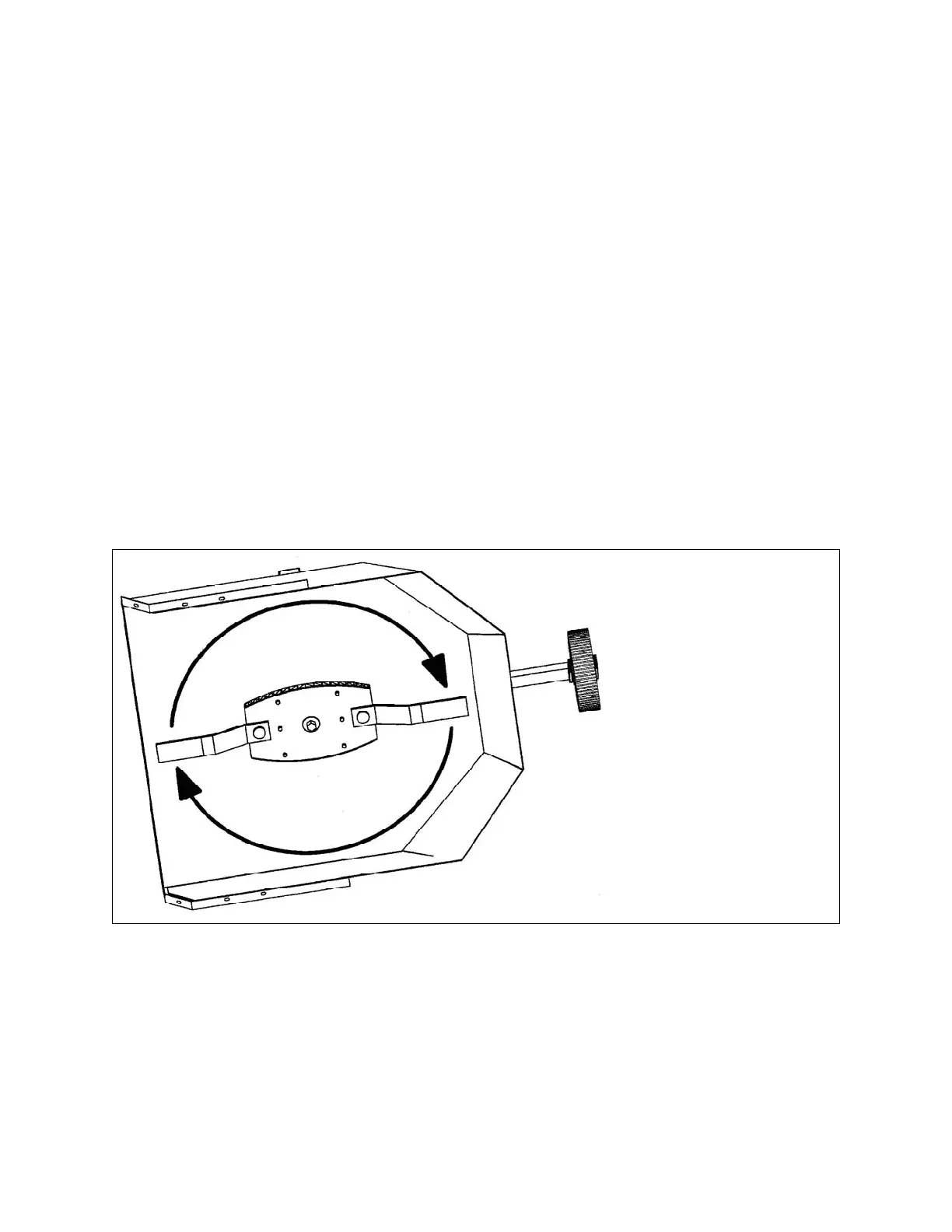

To replace the blades, proceed as follows (see fig. 8):

1. Remove the top inspection plate to gain access to the rotor.

2. Block the blade carrier rotor with a wrench and remove the blade bolt nut.

3. Remove the blade bolt and blade.

4. Check the bolt for wear. Replace if necessary.

5. Place the new blade making sure that the cutting edge is towards the direction of

rotation. The blade turns in a clockwise direction when viewed from the bottom of the

deck (see fig. 9).

6. Insert the blade bolt into the new blade and install into blade carrier rotor.

7. Properly torque the nut (M27-2.00 class 6.8) to 265 lb.ft.

IMPORTANT: Check blade bolt torque every 8 hours. Ensure the blades are able

to free-swing. This is extremely important to prevent damage to the cutter.

IMPORTANT: When installing new blades, it is important that they be the same

type and the same weight to ensure balance. An unbalanced rotor blade carrier

can damage the cutter.

MAINTENANCE 24 BEFCO

T

ORNADO RSD & RRB OPERATOR’S MANUAL

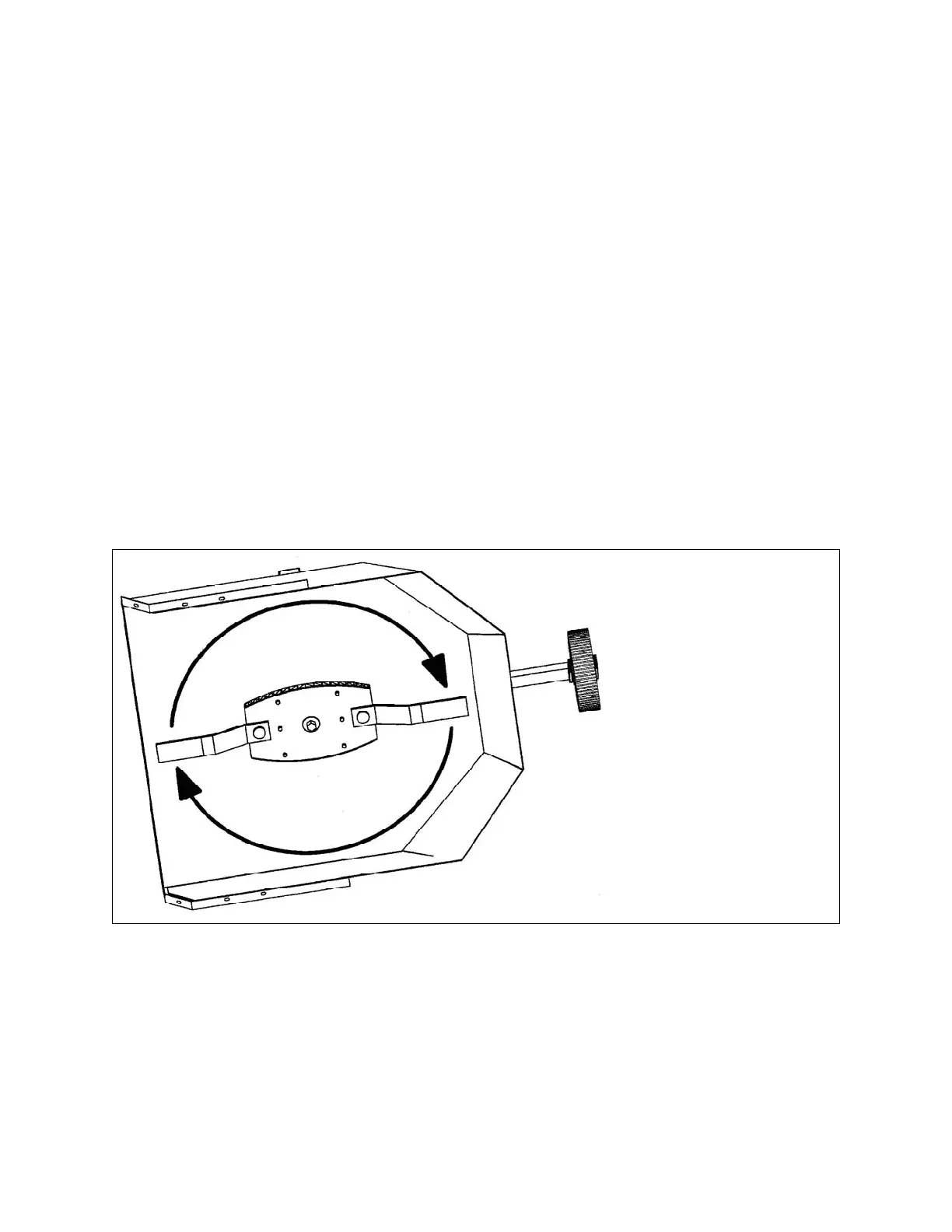

Fig. 9 - Direction of rotation.

The blades turn in a clockwise

direction when viewed from the

bottom of the deck.

Loading...

Loading...