ENGLISH

8

Switching off for long periods

In the event of lengthy periods of absence, set the function selector to

(OFF) (g. 34). The display will switch off.

Turn the main system switch OFF.

Turn off the fuel and water taps of the heating and domestic hot water

system. In this case, anti-freeze device is deactivated: empty the sys-

tems, in case of risk of frost.

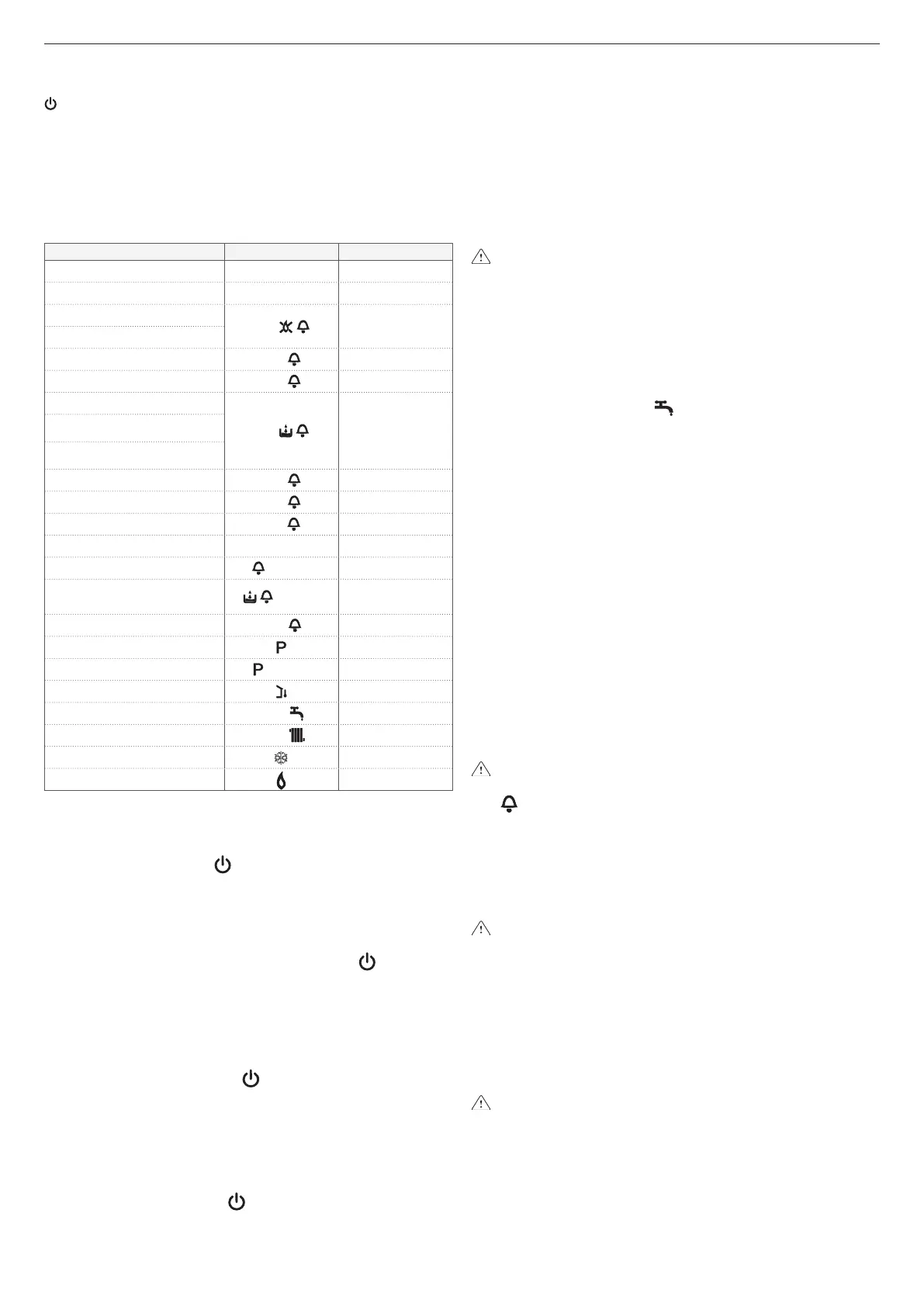

4.4 Operating status and faults

The operating status of the boiler is shown on the digital display, below

is a list of the types of displays.

Boiler status Dis

play

Type of alarm

Stand-by - Signal

OFF status OFF None

ACF alarm lockout module

A01

Denitive lockout

ACF electronics fault alarm

Limit thermostat alarm

A02

Denitive lockout

Air pressure switch alarm

A03

Denitive lockout

Water pressure switch alarm

A04

Denitive lockout

Anti-overow pressure switch

alarm

Reed sensor (if the condense

collector tray kit is installed)

NTC domestic water fault

A06

Signal

NTC heating fault

A07

Temporary stop

Parasite ame

A11

Temporary stop

Temporary, pending ignition 80°C ashing Temporary stop

Air pressure switch intervention

ashing

Temporary stop

Water pressure switch

intervention

ashing

Temporary stop

Calibration

ADJ

Signal

Preheating active function

Signal

Preheating heat request

ashing

Signal

External probe presence

Signal

Domestic water heat request

60°C

Signal

Heat request for heating

80°C

Signal

Antifreeze heat request

Signal

Flame present

Signal

Reset function

To restore operation (reset alarms):

Faults A01-02-03

Turn the function selector to OFF (fig. 34), wait 5-6 seconds, then

turn it to the required position. If the reset attempts do not reactivate the

boiler, contact the Technical Assistance Centre.

Fault A04

- Insufficient water pressure

Check the pressure value indicated by the water gauge:

if it is less than 0.5 bar, turn the function selector to OFF (fig. 34)

and adjust the filling tap until the pressure reaches a value between

1 and 1.5 bar.

Then turn the function selector to the required position.

If these pressure drops occur frequently, contact the Technical

Assistance Centre.

- Anti-overflow pressure switch

Position the mode selector on (OFF), wait for 5-6 seconds and

then turn it to the required position.

If the fault persists, contact the Technical Assistance Centre.

- Full basin (if the condense collector tray kit is installed)

Remove the basin and empty it (following the instructions supplied

with the kit).

Once the operations have been completed, replace the basin.

Turn the function selector to OFF, wait for 5-6 seconds and then

turn it to the required position.

If the fault persists, contact the Technical Assistance Centre.

Fault A06

The boiler functions normally but does not guarantee a constant

domestic hot water temperature, which remains set at around 50°C.

The intervention of the Technical Assistance Centre is necessary.

Fault A07

Request the intervention of the Technical Assistance Centre.

4.5 Adjustments

The boiler is factory-set by the manufacturer.

If it is necessary to adjust it again, for example after extraordinary main-

tenance, after replacement of gas valve or after gas conversion, carry

out the following procedure.

The maximum output adjustment must be carried out in the

sequence indicated exclusively by qualied personnel.

- remove the housing by loosening the xing screws A (g. 36)

- loosen the screw of the pressure test point downstream from the gas

valve by roughly two turns, then connect the pressure gauge

- disconnect the compensation inlet from the air distribution box

4.5.1 Maximum power and minimum domestic hot water ad-

justment

- Turn on a hot water tap to its maximum output on the control panel:

- set the function selector to (summer) (g. 37a)

- turn the domestic hot water temperature selector to its maximum

(g. 37b)

- power the boiler electrically by setting the main system switch to

“ON”

- check the pressure on the pressure gauge is stable, or use a milliam-

meter connected to the modulator to make sure the latter is receiving

the maximum available current (120 mA for G20 and 165 mA for

LPG)

- use a screwdriver to carefully prise the protection cap out of the ad-

justment screws

- using a fork spanner CH10 on the maximum output adjustment nut

to obtain the value indicated in the data table

- disconnect a modulator faston

- wait until the pressure shown on the pressure gauge is stable at

minimum value

- use an Allen spanner to set the red adjustment screw of the DHW

minimum, calibrating it until the pressure gauge shows the value in-

dicated in the data table

- reconnect the modulator faston

- turn off the domestic hot water tap

- carefully ret the protection cap of the adjustment screws.

4.5.2 Minimum and maximum heating electric adjustment

The “electric adjustment” function is activated and deactivated ex-

clusively by the jumper (JP1) (g. 39).

ADJ appears on the display, indicating that the calibration proce-

dure is in progress.

The function can be enabled in the following ways:

- by powering the card with jumper JP1 inserted and the function se-

lector in the winter position, regardless of the possible presence of

other operation requests.

- by inserting jumper JP1, with the function selector in the winter posi-

tion, without any heat request in progress.

By activating the function the burner is ignited through simulation

of heat request in heating.

To perform calibration operations, proceed as follow:

- switch off the boiler

- remove the housing and the terminal board cover, loosening the

screw B (g. 39) to access the card

- insert jumper JP1 (g. 39) to enable the minimum/maximum heating

adjustment functions of the knobs on the control panel.

- make sure the function selector is in the winter position (see para-

graph 4.2).

- power the boiler

Electric card live (230 Volt)

- turn the heating water temperature adjustment knob B (g. 40) until it

reaches the minimum heating value as indicated in the multigas table

- insert jumper JP2 (g. 39)

- turn the DHW temperature adjustment knob C (g. 40) until it reach-

es the maximum heating value as indicated in the multigas table

- remove jumper JP2 to store the maximum heating value

- remove jumper JP1 to store the minimum heating value and to

quit the calibration procedure

- reconnect the compensation inlet to the air distribution box.

Loading...

Loading...