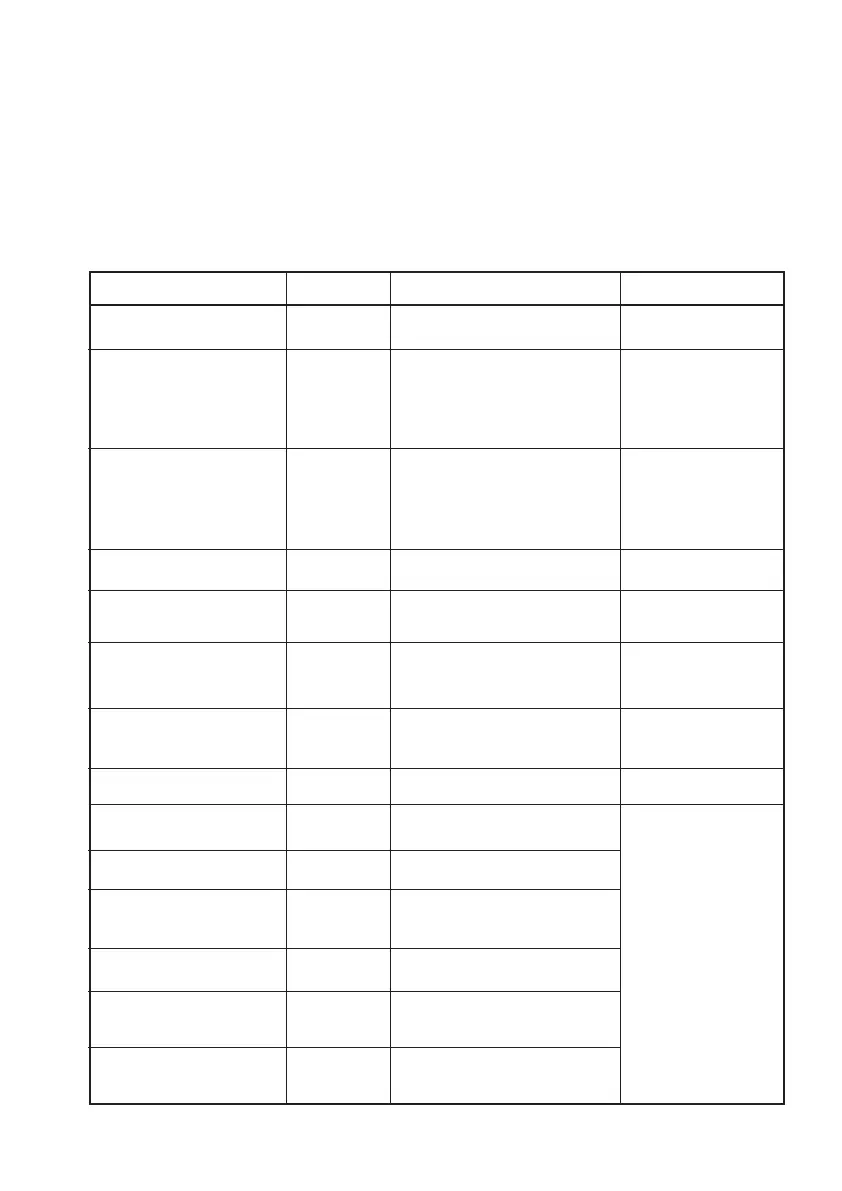

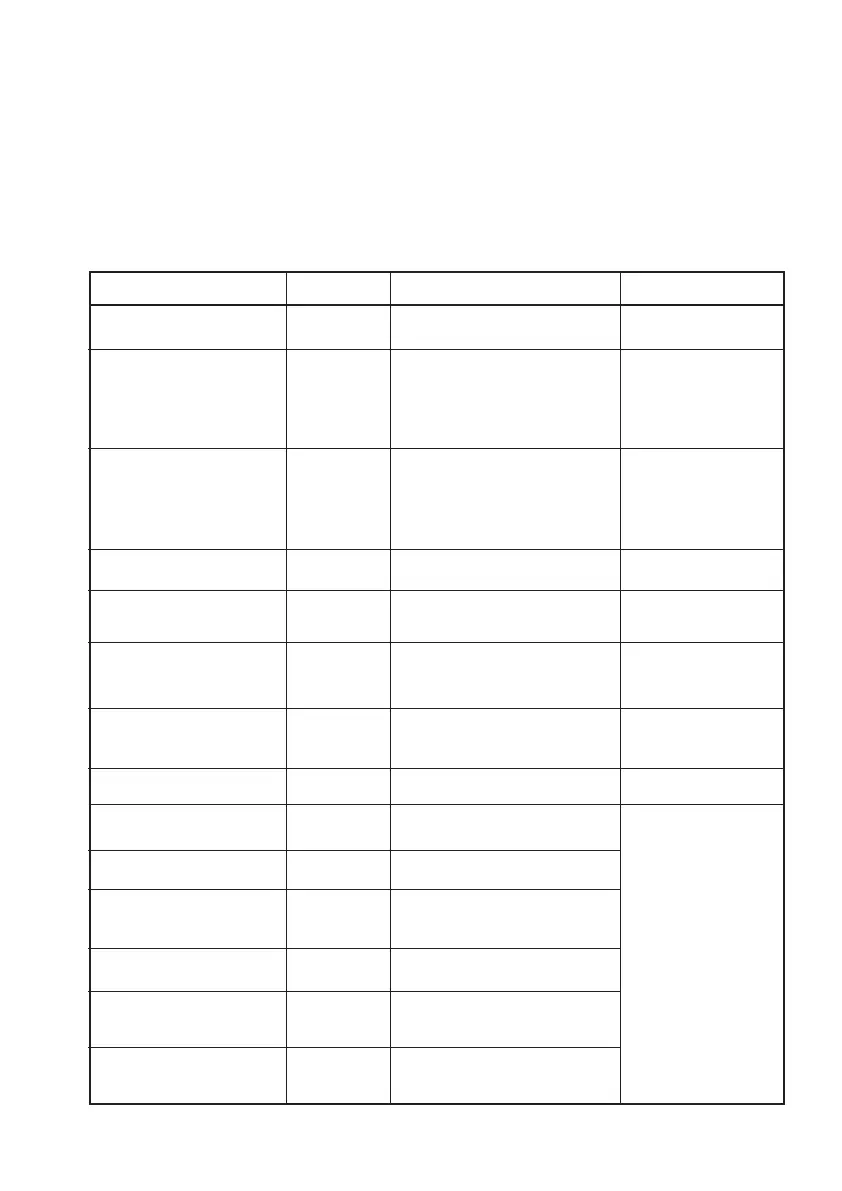

Part description Quantity Details Time/Frequency

Engine Oil O O O

Transmission oil 3,5 L Replace with gear oil First time: after

type SAE 15W/40 50 hours operation.

After rst time:Every

100 hours operation

Hydraulic oil Add or replace hydraulic First time: after

TR”D” oil with ISO VG 46 20 hours operation.

After rst time:

Every 50 hours op.

Air Filter O O

Fuel Pipe Replace pipe and Replace pipe

check connections every two years

Electric system Check there are no Every year

peelings or damages

Inspecting the brakes. run water under pression in line with the

operating conditions

Plug O O

Crawlers 10÷15 mm Adjust divergence grade Refer to your dealer

Axle shafts unlock lever Check if machine can turn

Brake lever and Control brake efciency

parking brake

Clutch lever Check that belt does not slip

Assembly bolts of Fixing agent

the guide rollers

Assembly bolts Fixing agent

of the engine

CHAPTER 6 MAINTENANCE

1. How to determine timing for regular maintenance

In order to avoid accidents caused by using the machine under wrong conditions,

take the machine to your closest authorised dealer or to a repair workshop and

have them check the safety of the machine’s various components. In particular,

make sure to replace the fuel pipe every two years and check the electric system

once a year.

Tables for regular maintenance

O Refer to indications mentioned in the engine’s “Use and Maintenance” handbook

Loading...

Loading...