BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

OPERATION ADVICE

• Remove the McPherson spring strut.

• Select jaws according to table (page 32-46) and mount on the spring compressor. Fit the

retaining bolts and tighten firmly.

• It is very important for your safety that the bolts of the jaws are firmly tightened.

• Rotate the drive nut to drive the jaws apart to match the length of the spring and to compress as

many windings as possible.

• Place the coil spring compressor in the built-in protective accessory in a suitable vice.

• Place the spring strut onto the coil spring compressor. Take care that the seating of the spring

windings in the jaws is correct.

• With an impact wrench or a racket spanner, turn the drive nut until the upper support bearing is

free. Additional compressing is permitted.

• When using impact wrench do not exceed 180Nm torque limit.

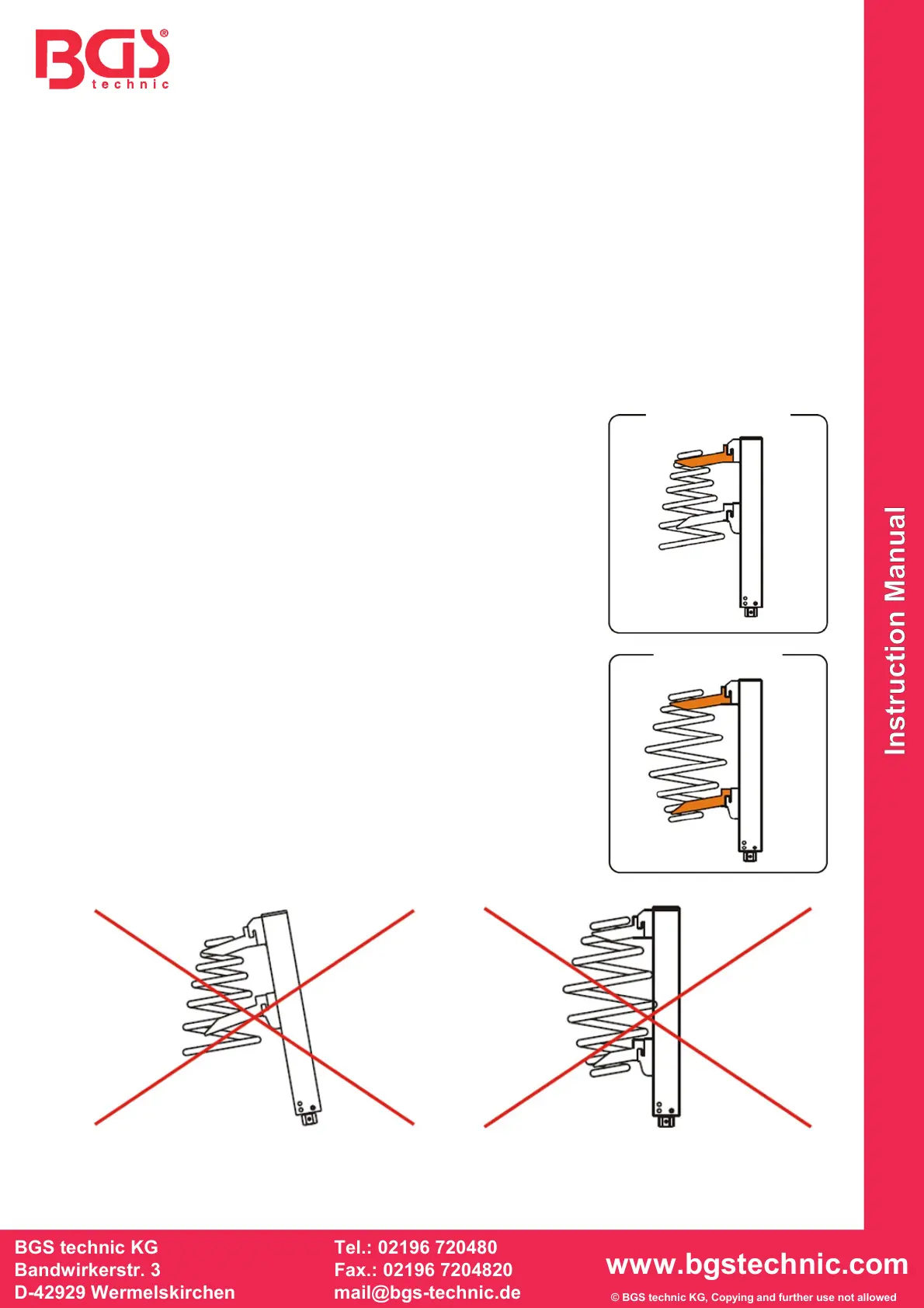

Conical Springs

Use the raised jaw to ensure that the centre line of the spring is

parallel to the compressing device.

Do not use the coil spring compressor for conical springs if this is

not the case.

Fit the raised jaw at the spring end with the smallest diameter.

It is very important for your safety that the jaws are fitted correctly

and that the bolts are firmly tightened before use.

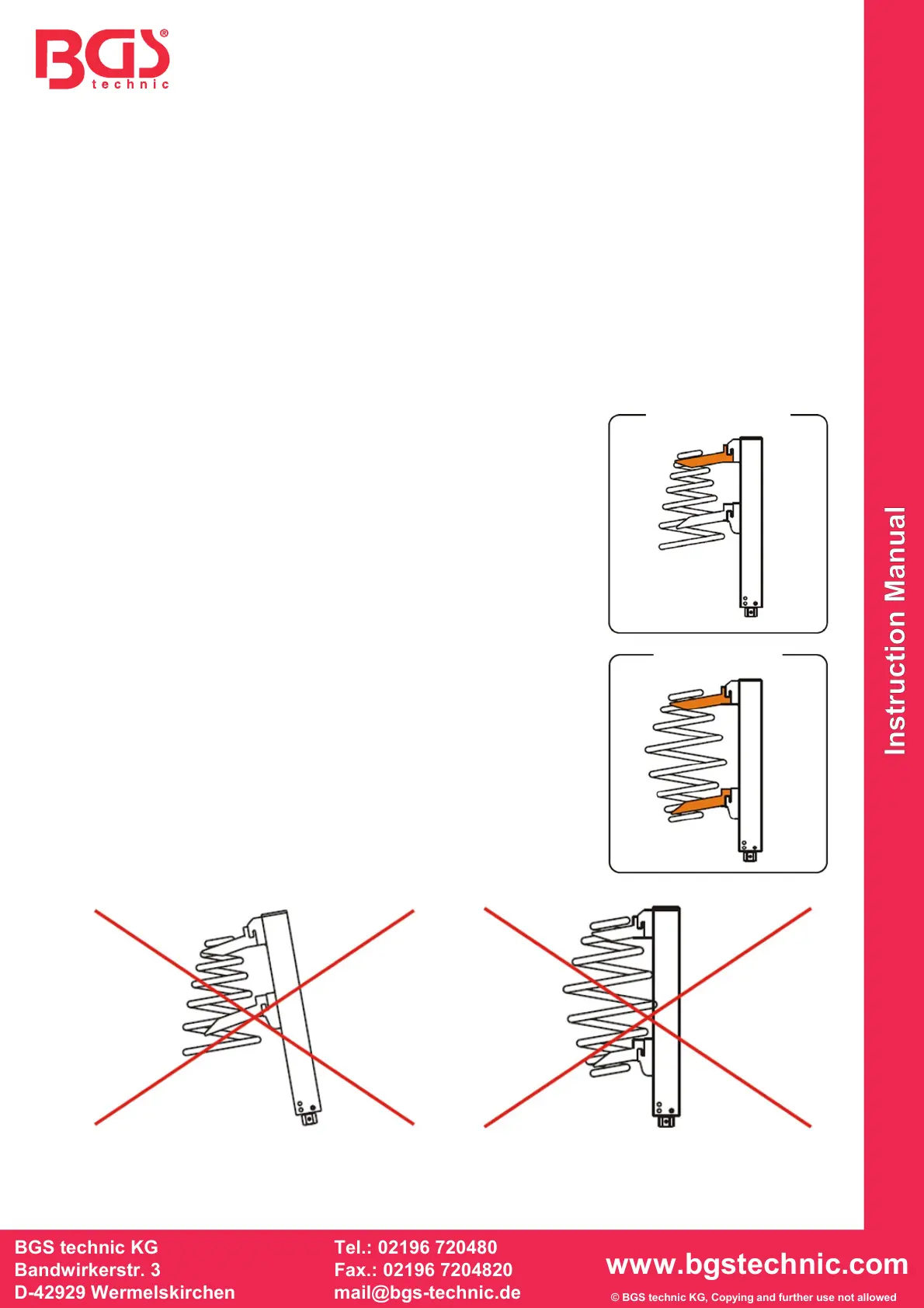

Ball Springs

Use the raised jaw to ensure that the centre line of the spring is

parallel to the compressing device.

Do not use the coil spring compressor for ball springs if this is not

the case.

Fit raised jaws at both spring ends.

It is very important for your safety that the jaws are fitted correctly

and that the bolts are firmly tightened before use.

Loading...

Loading...