7

8

4 5 6

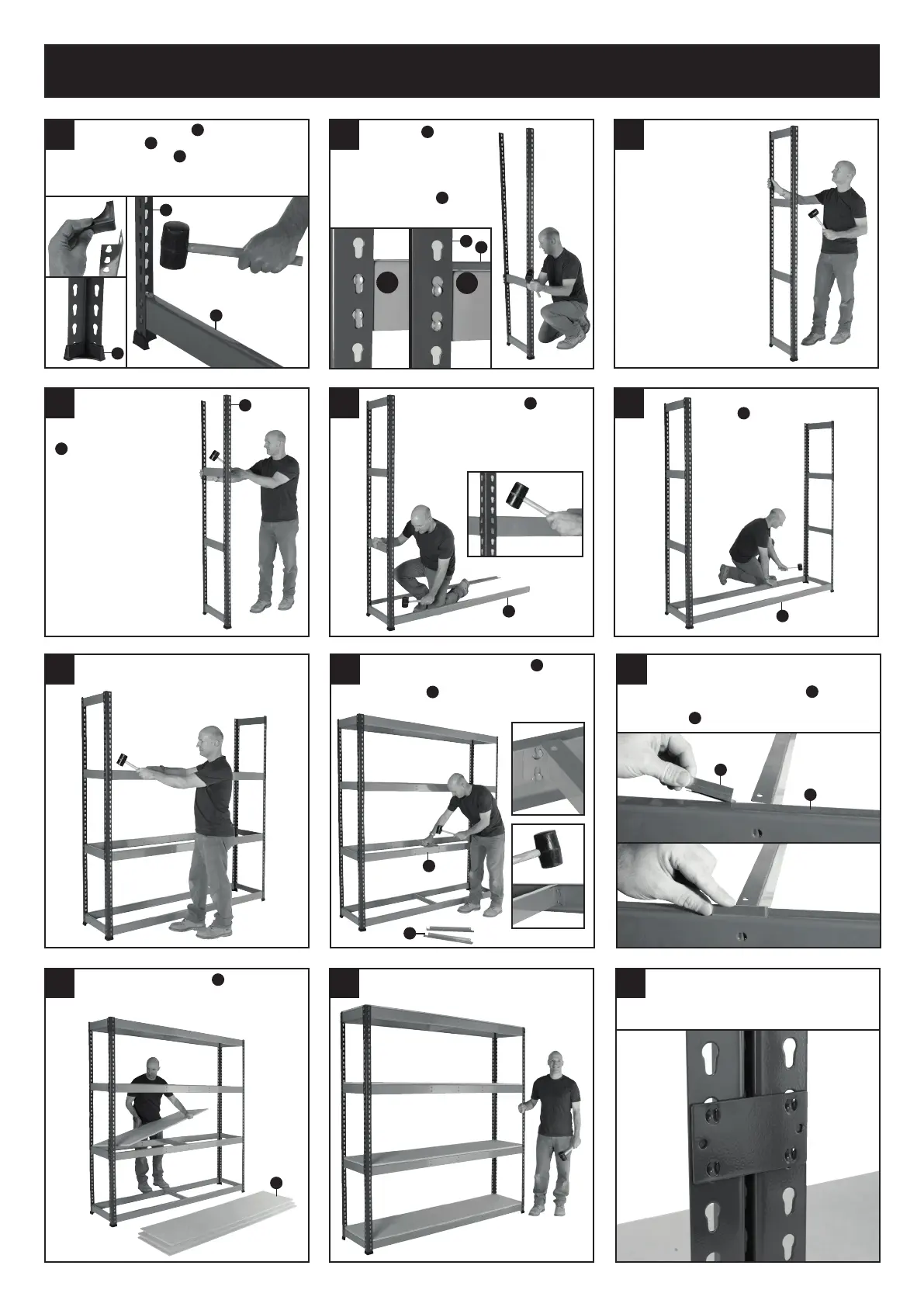

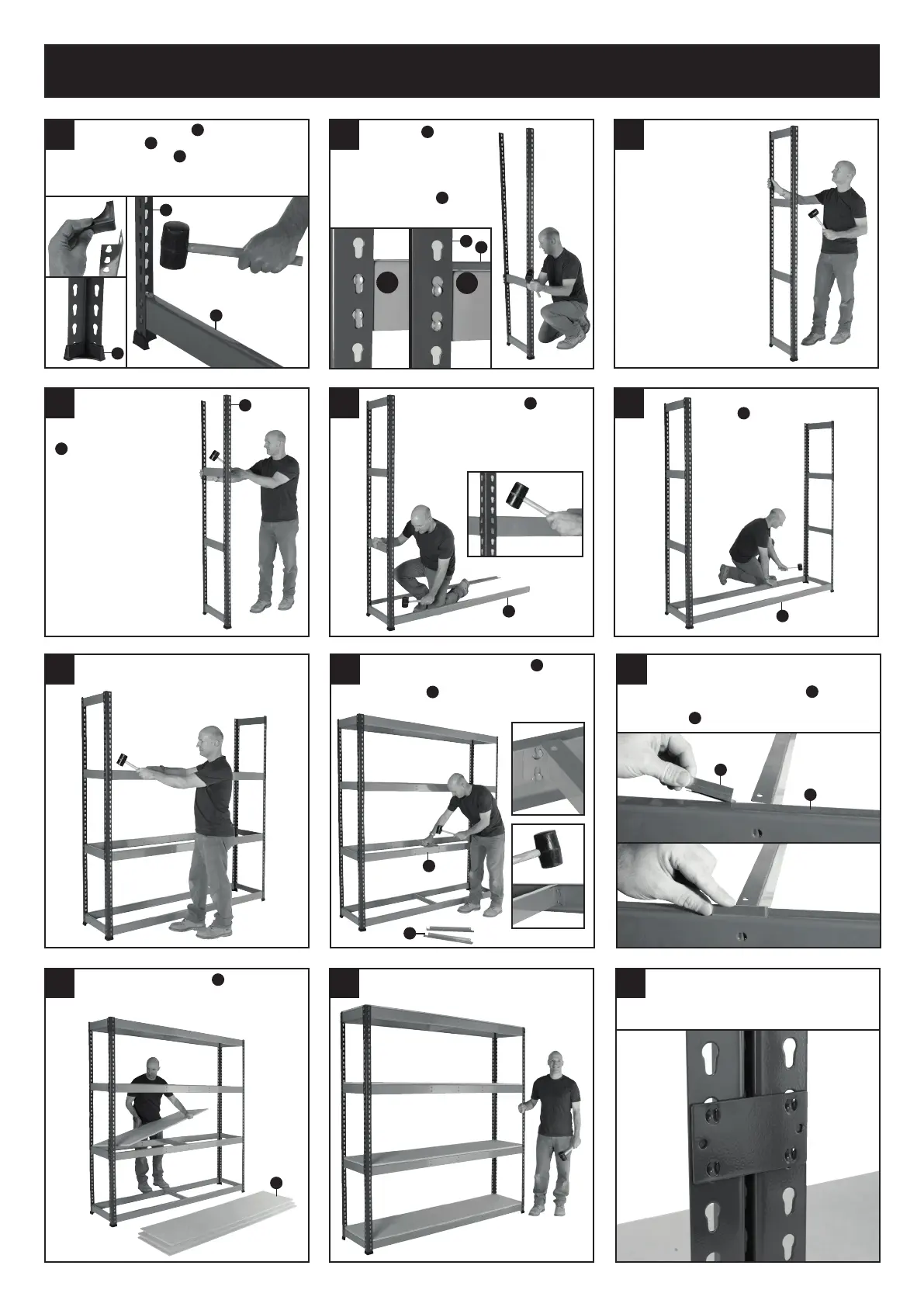

Assembly - BiG400/BiG800

1 2 3

Select two uprights

A

and push on

plastic feet

G

to the bases. Insert a

short side beam

C

into the keyholes at

the lowest shelf level required. Ensure

the beam is 90 degrees to the upright

Tap beam

C

with a

rubber mallet to ensure

the end studs are fully

located in the bottom of the

keyholes on both uprights.

Lean the uprights

A

against

a wall for support if needed

Repeat steps 1 and 2

until you have created a

“ladder style frame”

Select two more uprights

A

and repeat steps 1 to

3 until you have a second

“ladder style frame”

Locate a centre support beam

(D)

onto

the metal studs on the centre of each

long beam

(B)

. Tap into place and repeat

for all levels

12

Tip: Use the rst frame

as a template to get the

correct spacing

Take two long beams

B

and

insert them into the keyholes on

one frame at the same height as

the short beams. Tap into place

with a rubber mallet

Repeat steps 5 and 6 to add the

remaining long beams. Ensure that

each long beam is located at the

same height as the side beams

Tip: Now is a good

time to check the

space between beams

suits the items you

want to store on the

shelves and adjust as

required

O

P

Insert the other ends of the

beams

B

into the second

frame as in step 5

Tip: Ask another

person to hold the

frames in place

while you secure

them

Shelving bays can be joined together

with tie plates. Use 4 per join - 2 front

and back. Tap into place with a rubber

mallet

11

The bay is now complete and ready

to use

B

A

C

C

A

A

B

D

B

G

9

If you have wide shelving then the

chipboard may be in 2 pieces per level.

Slide the chipboard joiners

(F)

supplied

onto the centre of each front & back

beam

(B)

before adding the chipboard

F

B

F

B

10

Insert chipboard decks

(E)

into each

level - decks sit on the top of the beams

inside the posts

E

E

B

D

Loading...

Loading...