3

INSTALLATION

Installation onto Drum Mounted Agitator Units

(refer to page 1 and figure 1, page 5)

1

. Align holes on coupling adapter (30) to the mounting

holes on the stuffing box assembly (17). Secure with

lock washers (23) and hex head bolts (24).

2. Apply medium strength thread lock to set screw (28),

then screw into coupling (26).

3. Align the set screw (28) with the set screw detent on

the drive shaft assembly (27). Tighten set screw.

4. Align coupling (26) with the pin (10) on agitator shaft.

Drop down over agitator shaft (11).

5. Rotate gear reducer (25) and air motor (39) until the

square flats on the drive shaft assembly (27) line up

with the female flats in the bottom of gear reducer (25).

Drop down to top of coupling adapter (30).

6. Align the inlet for the air supply after mounting. This is

accomplished by rotating the gear reducer with air

motor (25 and 39) to the desired position to connect the

air supply. Tighten hex head cap screw (29).

7. Connect the air supply to the air motor.

OPERATION

Before operating air motor, lubricate as covered in next

section. Open valve to main air line; then slowly open air

adjusting valve until agitator turns. To extend air motor

life, adjust air pressure setting to run motor at about one

revolution per second. The agitator should be run contin-

uously while in use.

PREVENTIVE MAINTENANCE

Air Motor Lubrication

Periodically – Remove air adjusting valve and air strainer

and flush motor with a clean suitable solvent. Remove

trapped particles from screen in air inlet and clean air

strainer felt.

Air Motor Gear Box Lubrication

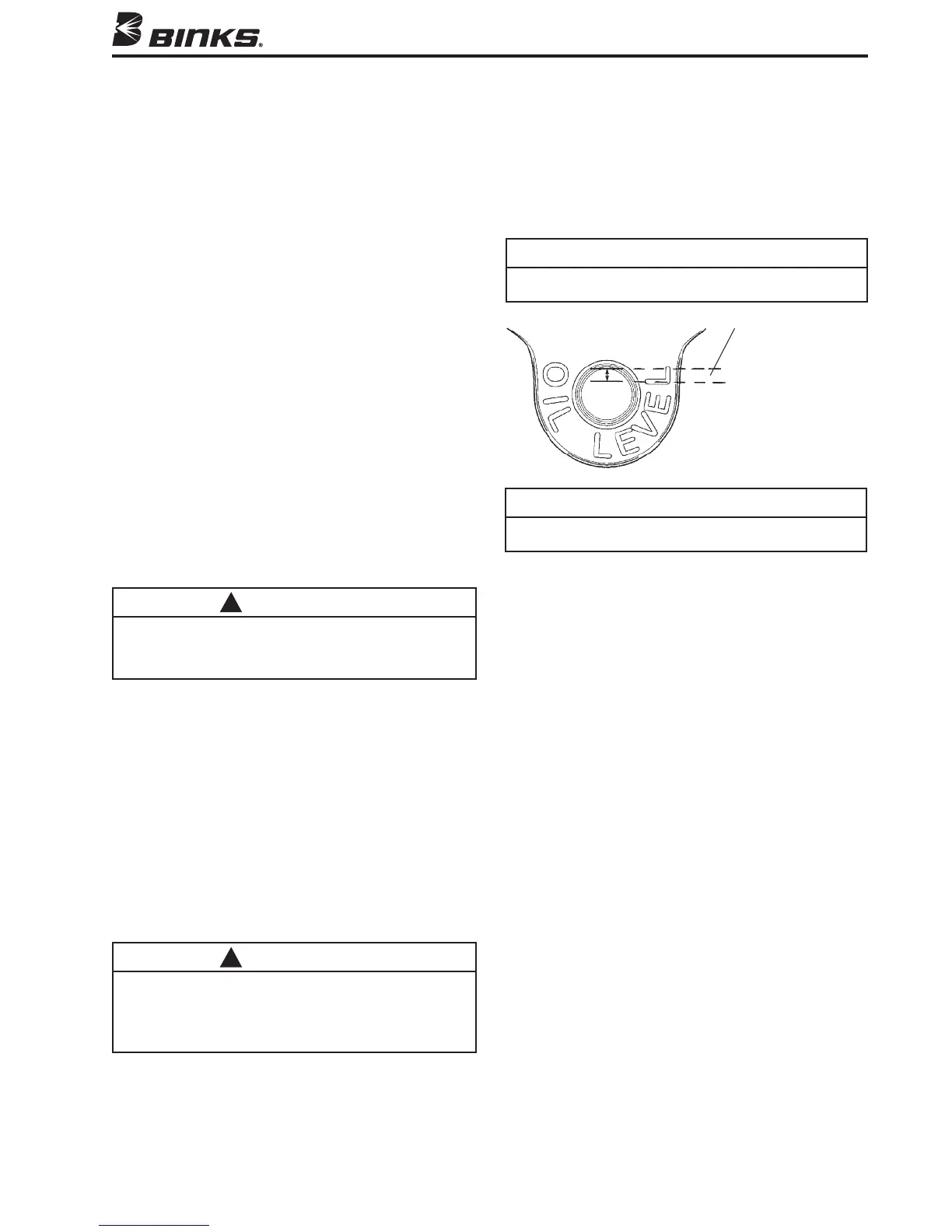

Every 2 Days – Remove oil fill plug and check oil level.

Proper oil level is indicated on outside of gear box hous-

ing. If oil level is low, add 140-weight SAE Gear Oil or

a

high quality worm gear lubricant. Replace pipe plug

and tighten to 20 foot-pounds (27 N-m) of torque.

After first 250 hours of operation, remove gear box and

drain gear oil. Refill gear box with 140-Weight SAE Gear

Oil or a high quality worm gear lubricant. Replace pipe

plug and tighten to 20 foot-pounds (27 N-m) of torque.

Six months or 2500 Operating Hours – Replace gear oil

according to instructions above. Replace gear oil more

often if environment causes oil to become contaminated

during use.

REPLACEMENT OF PARTS

Removal of Air Motor and Gear Box

(refer to figure 1, page 5 – typical assembly.)

1. Turn off valve to main air supply and disconnect air

adjusting valve (38) at nipple (37).

2. Loosen cap screw (29) and remove air motor and gear

box assembly from coupling adapter (30).

Air Motor (refer to figure 2, page 6)

Holes must be drilled for new dowel pins (44) after

assembling front plate (49) on new body (48) for align-

ment of parts.

Do not pry front plate (49) or end plate (43) from air

motor body (48) with a screw driver; this will dent the

surface of the body and plates causing leaks. A puller tool

should be used to remove the plate from the motor body

while maintaining the position of the shaft.

CAUTION

The gear reducer is shipped with a plastic 1/4 NPT plug to

prevent leakage. Make sure the plastic plug on top of the

gear reducer has been replaced with the QS-108 vented oil

fitting (Item No. 55, page 7) before operation.

!

OPERATION AND MAINTENANCE

(continued on page 4)

CAUTION

Failure to properly lubricate the air motor will result in

premature motor failure and will void warranty.

Lubricate air motor daily by adding 4 or 5 drops of SAE 10

weight oil into air inlet fitting. For convenience, an automatic

oiler may be connected to the air inlet.

!

NOTE

Gear box oil is most easily drained just after motor opera-

tion, while oil is still warm.

NOTE

Do not overfill. Overfilling may cause oil to leak out of vent

cap on top of gear box.

Approx. 1/8" gap

(top of oil level to

bottom of fill hole)

Loading...

Loading...