Do you have a question about the Black & Decker H11955F and is the answer not in the manual?

Manual provides installation, use, maintenance and safety information.

Follow recommendations to avoid personal injuries or damage.

Details hazards like hot parts, electrical risks, air quality, and proper use.

Adhere to max pressure limits and safety valve settings.

Avoid welding on tank; ensure periodic inspection and potential replacement.

Manual helps optimize performance, guarantee safe use, and guide maintenance.

Use mineral oil and original parts; contact service for issues.

Keep the pressure vessel certificate with the manual.

Inspect for freight damage and report issues immediately.

Illustrates various suggested uses for the air compressor.

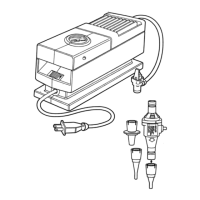

Details the included accessories for specific models.

Provides detailed technical data for different models.

Identifies and explains the function of each major component.

Instructions for product assembly and choosing a suitable installation location.

Guidance on maintaining distance for ventilation and maintenance.

Advice on achieving oil and dust-free air for specific services.

Details on ensuring proper electrical supply and protection.

Check oil level and ensure pressure regulator valve is open.

Run compressor for 10 mins for lubrication, then test pressure switch.

Drain condensed water from the tank after initial use.

Connect to air network and check for leaks.

Instructions for fastening nozzles and air kit hoses.

Steps to start compressor, fill tank, and adjust pressure.

Procedure for resetting thermal protector in case of overheating.

Guidance on preparing surfaces and using the spray gun.

Tips for proper movement pattern and paint application.

Steps to clean and lubricate the spray gun after use.

Check oil level and drain condensed water daily.

Recommended lubricant oil type (ISO VG 100 or SAE 30).

Specifies intervals for first and subsequent oil changes.

Detailed procedure for changing the compressor oil.

Clean compressor exterior and air filter element.

Check and tighten fastening bolts every 15 days.

Check pressure switch and start up procedure items.

Replace air filter every 300 hours; re-fasten bolts and nuts.

Calibrate pressure switch, gauge, and safety valve annually.

Check and clean cylinder valves every 1000 hours or 12 months.

Provides torque specifications for cylinder head bolts.

Repairs should be performed by Authorized Service Center using original parts.

Troubleshooting for motor not starting, overheating, or abnormal vibration.

Addresses reduced air production and overheating.

Troubleshooting for tank pressure increase and insufficient pressure.

Addresses air leakage and high temperature of compressed air.

Troubleshooting for excessive oil consumption, unusual oil color, and dirt.

Addresses ambient temperature, operating pressure, and valve adjustments.

Lists contact information for Black & Decker in various countries.

| Brand | Black & Decker |

|---|---|

| Model | H11955F |

| Category | Air Compressor |

| Language | English |

Loading...

Loading...